Method for preparing suede-like surface structure of crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of unsuitable industrial production and low conversion efficiency of cells, and achieve the effects of reducing processing costs, being suitable for popularization and application, and having obvious advantages in efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a textured structure of a polycrystalline silicon solar cell, comprising the following steps:

[0038] (1) Clean the silicon wafer and remove the surface damage layer;

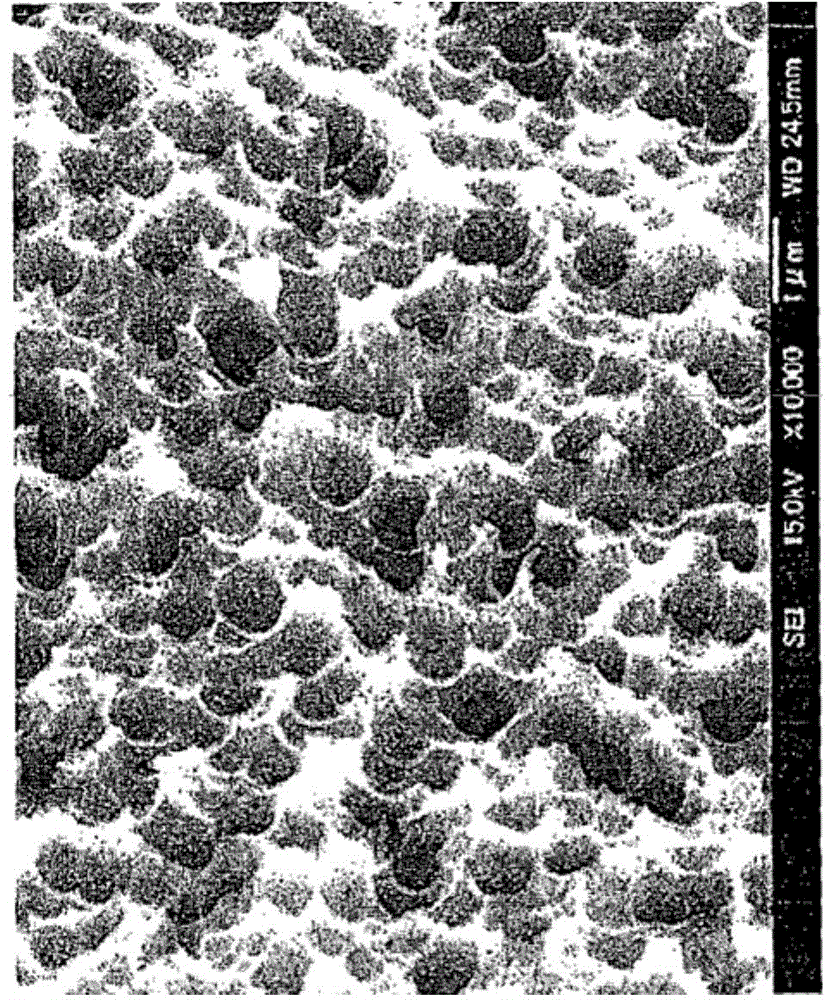

[0039] (2) Put the above-mentioned silicon chip into a chemical etching solution containing metal ions to form nanowires or porous silicon structures on the surface of the silicon chip; the temperature is 30°C, and the time is 200 seconds;

[0040] The metal ion is selected from silver ion;

[0041] The chemical etching solution is selected from HF and H 2 CrO 4 mixed solution; wherein, the concentration of HF is 10 mol / L, H 2 CrO 4 The concentration is 0.4 mol / L;

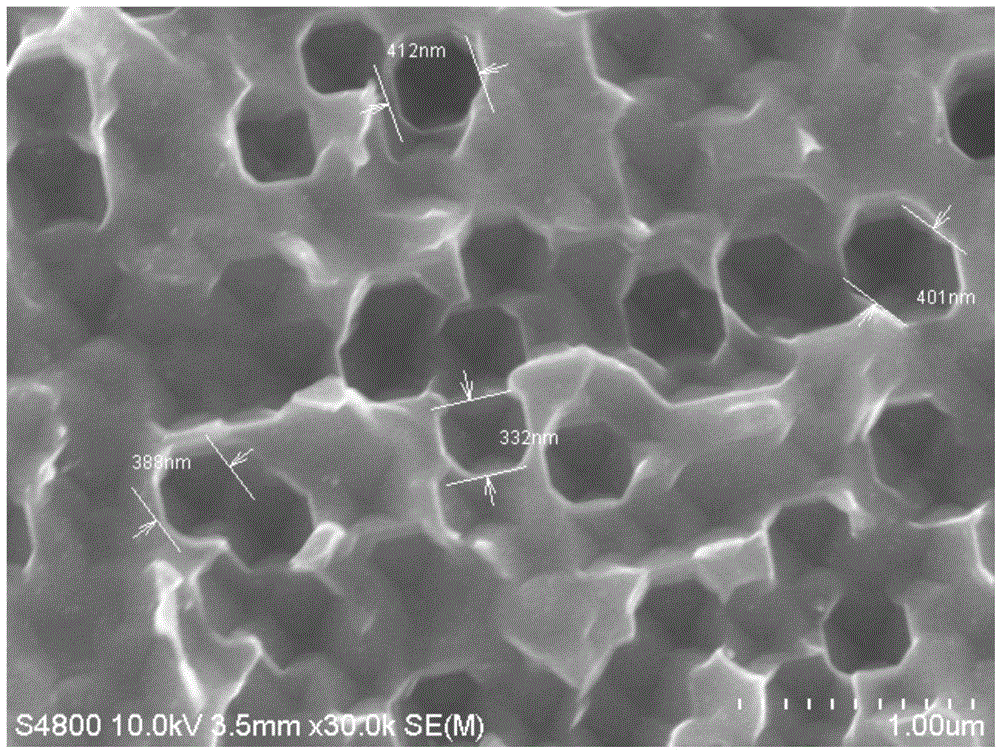

[0042] (3) Putting the above-mentioned silicon chip into the first chemical etching solution for corrective etching, so that the above-mentioned nanowire or porous silicon structure forms a nano-deep hole structure;

[0043] The first chemical etching solution is H 2 CrO 4 and HF mixed acid solution, wherein th...

Embodiment 2

[0055]A method for preparing a textured structure of a polycrystalline silicon solar cell, comprising the following steps:

[0056] (1) Clean the silicon wafer and remove the surface damage layer;

[0057] (2) Put the above-mentioned silicon chip into a chemical etching solution containing metal ions to form nanowires or porous silicon structures on the surface of the silicon chip; the temperature is 30°C, and the time is 200 seconds;

[0058] The metal ion is selected from silver ion;

[0059] The chemical etching solution is selected from HF and H 2 CrO 4 mixed solution; wherein, the concentration of HF is 10 mol / L, H 2 CrO 4 The concentration is 0.4 mol / L;

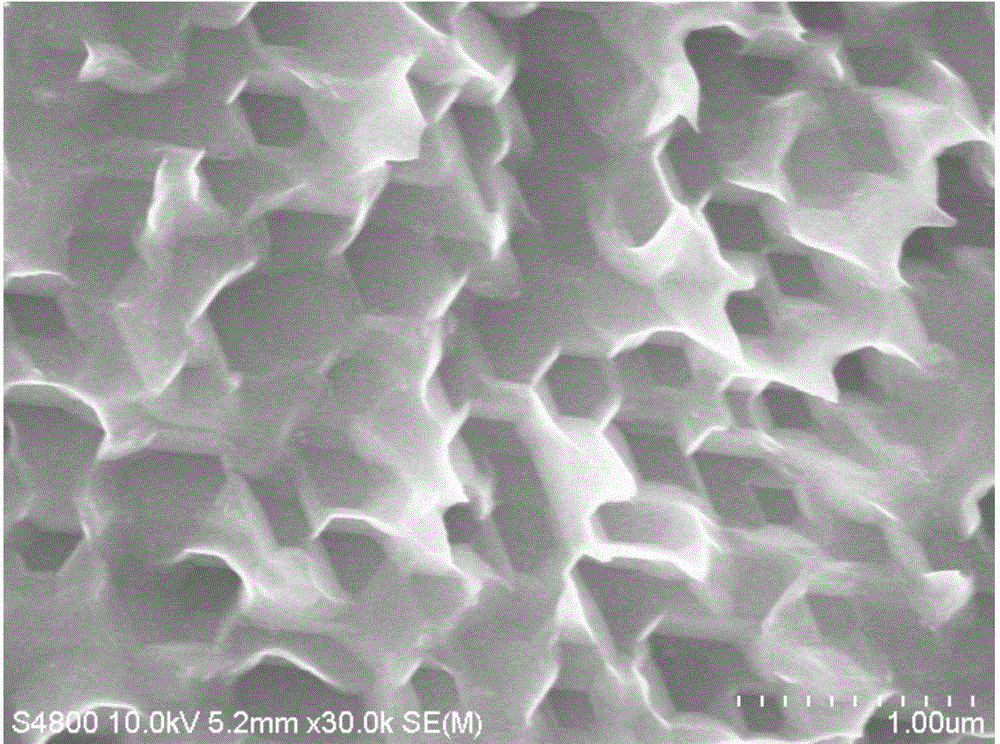

[0060] (3) Putting the above-mentioned silicon chip into a chemical etching solution for corrective etching, so that the above-mentioned nanowire or porous silicon structure forms a nano-concave structure;

[0061] The chemical corrosion solution is selected from tetramethylammonium hydroxide solution; its concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com