Preparation method for medical metal implant surface chitosan quaternary ammonium salt/collagen composite coating

A chitosan quaternary ammonium salt and composite coating technology, which can be used in coatings, prostheses, medical science, etc., can solve the problems of limited coating control, limited improvement of bearing capacity, and decreased electric field responsiveness, and achieve release behavior. Controllable adjustment, increased capacity, the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

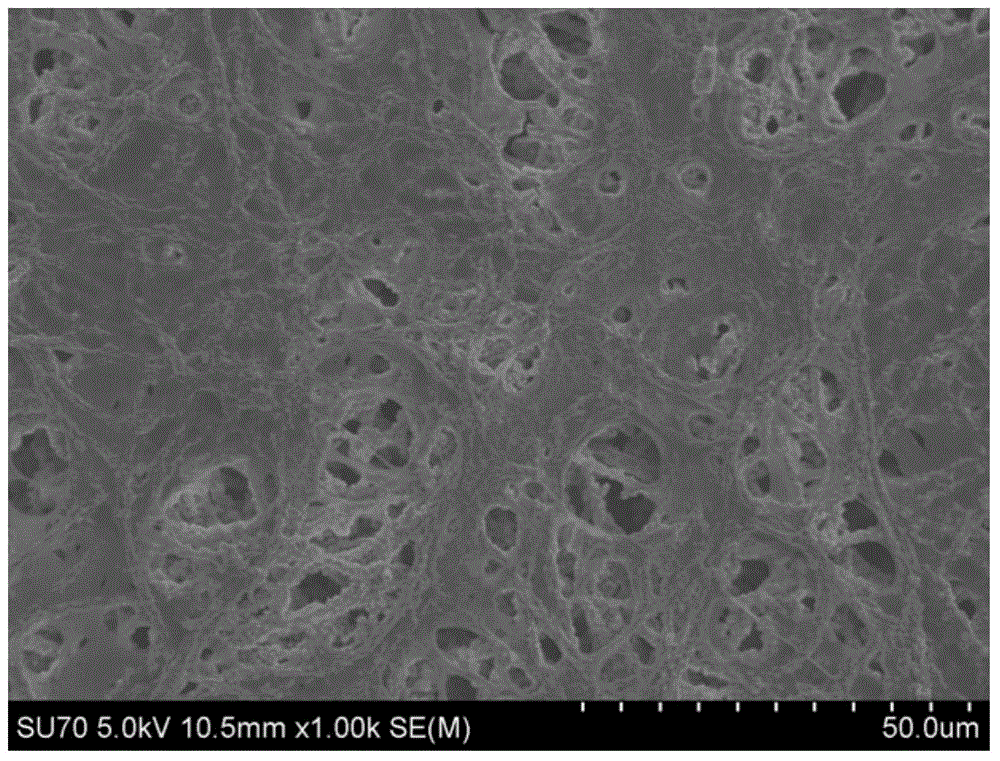

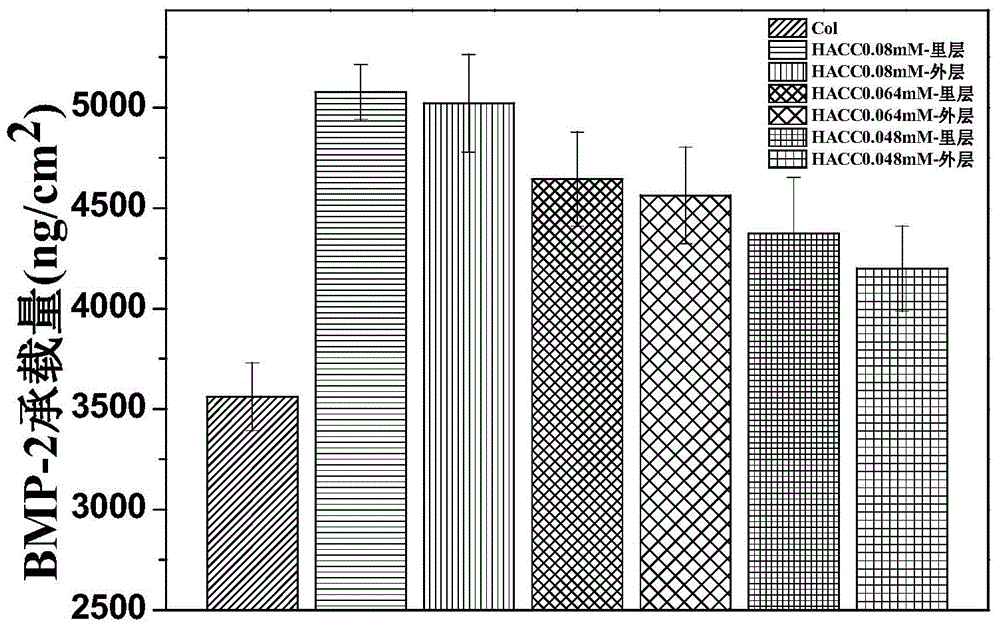

Embodiment 1

[0023] 1) quaternary ammonium root substitution degree is 98%, molecular mass is 30000 2-hydroxypropyltrimethylammonium chloride chitosan is dissolved in distilled water, preparation concentration is the chitosan quaternary ammonium salt aqueous solution of 0.5g / L, put Stand-by at 4°C; dissolve Beiling liquid type I collagen in 0.005mol / L acetic acid to prepare a collagen acetic acid solution with a concentration of 0.5g / L, and place it at 4°C for use;

[0024] 2) Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O is dissolved in water and prepared as Ca(NO 3 ) 2 aqueous solution, the NH 4 h 2 PO 4 Dissolved in water, prepared as NH with a phosphorus concentration of 80mmol / L 4 h 2 PO 4 aqueous solution, the Ca(NO 3 ) 2 Aqueous solution and NH 4 h 2 PO 4 The aqueous solution was stirred and mixed to obtain A solution. Mix Beiling liquid type I collagen, 2-hydroxypropyltrimethylammonium chloride chitosan solution with solution A to make the quaternary ammonium root ...

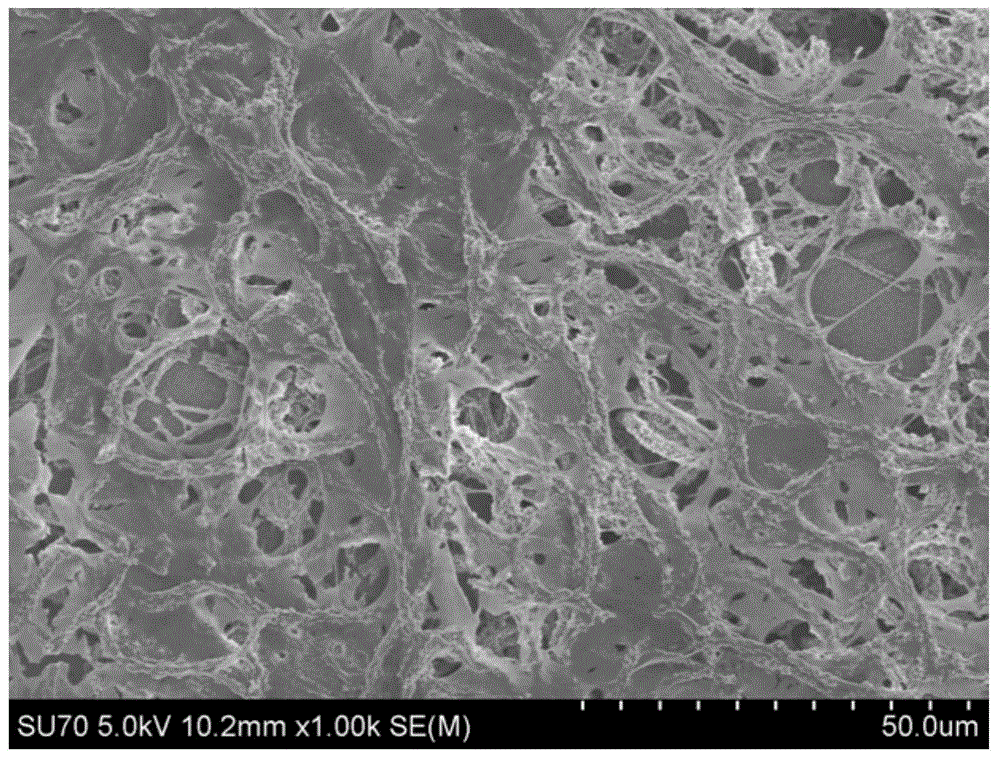

Embodiment 2

[0028] 1) quaternary ammonium root substitution degree is 98%, molecular mass is 30000 2-hydroxypropyltrimethylammonium chloride chitosan is dissolved in distilled water, preparation concentration is the chitosan quaternary ammonium salt aqueous solution of 0.5g / L, put Stand-by at 4°C; dissolve Beiling liquid type I collagen in 0.005mol / L acetic acid to prepare a collagen acetic acid solution with a concentration of 0.5g / L, and place it at 4°C for use;

[0029] 2) Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O is dissolved in water and prepared as Ca(NO 3 ) 2 aqueous solution, the NH 4 h 2 PO4 Dissolved in water, prepared as NH with a phosphorus concentration of 80mmol / L 4 h 2 PO 4 aqueous solution, the Ca(NO 3 ) 2 Aqueous solution and NH 4 h 2 PO 4 The aqueous solution was stirred and mixed to obtain A solution. Mix Beiling liquid type I collagen, 2-hydroxypropyltrimethylammonium chloride chitosan solution with solution A to make the quaternary ammonium root an...

Embodiment 3

[0033] 1) quaternary ammonium root substitution degree is 98%, molecular mass is 30000 2-hydroxypropyltrimethylammonium chloride chitosan is dissolved in distilled water, preparation concentration is the chitosan quaternary ammonium salt aqueous solution of 0.5g / L, put Stand-by at 4°C; dissolve Beiling liquid type I collagen in 0.005mol / L acetic acid to prepare a collagen acetic acid solution with a concentration of 0.5g / L, and place it at 4°C for use;

[0034] 2) Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O is dissolved in water and prepared as Ca(NO 3 ) 2 aqueous solution, the NH 4 h 2 PO 4 Dissolved in water, prepared as NH with a phosphorus concentration of 80mmol / L 4 h 2 PO 4 aqueous solution, the Ca(NO 3 ) 2 Aqueous solution and NH 4 h 2 PO 4 The aqueous solution was stirred and mixed to obtain A solution. Mix Beiling liquid type I collagen, 2-hydroxypropyltrimethylammonium chloride chitosan solution with solution A to make the quaternary ammonium root ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com