Controllable-degradation lacrimal passage suppository and preparation method thereof

A lacrimal duct plug and collagen matrix technology, applied in medical science, surgery, etc., can solve problems such as difficulty in judging plugs, formation of packages, displacement and deterioration of the condition, avoiding ocular surface damage, simplifying the preparation method, and avoiding epiphora. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

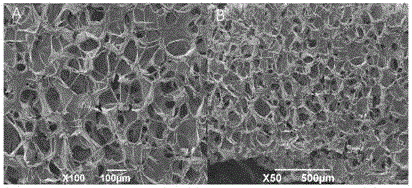

[0035] Reference Methods Collagen was purified from bovine tendon and dissolved in 2% acetic acid solution to obtain a 1% collagen solution.

[0036] Cross-linking: EDC with a mass fraction of 0.01% was added to the above collagen solution, the cross-linking time was 24 hours at 25°C, and the stirring speed was 80r / min. Then, the purified water was used for repeated dialysis and vibration washing, and the liquid was changed every 8 hours, and the liquid was changed 3 times in total.

[0037] Homogenization: adding an appropriate amount of purified water to the obtained cross-linked collagen matrix for homogenization at 4°C until a fine and uniform gel-like substance with a viscosity of 800 mPa / s is formed.

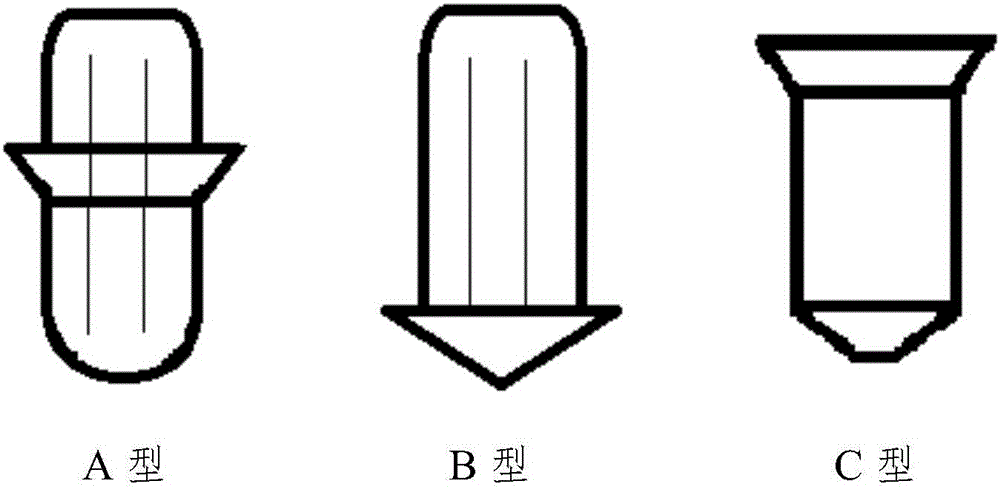

[0038] Molding and freeze-drying: transfer the gel into a mold for freeze-drying to obtain a sample with a specified structure. There are 4 axial grooves evenly distributed on the surface of the A and B-type samples; The needle passes through the center of the C-type samp...

Embodiment 2

[0040] Reference Methods Collagen was purified from bovine tendon and dissolved in 2% acetic acid solution to obtain a 10% collagen solution.

[0041] Cross-linking: EDC with a mass fraction of 0.5% was added to the above collagen solution, the cross-linking time was 16 hours at 4°C, and the stirring speed was 300 r / min. Then, the purified water was used for repeated dialysis and vibration washing, and the liquid was changed every 4 hours, and the liquid was changed 6 times in total.

[0042] Homogenization: adding an appropriate amount of purified water to the obtained cross-linked collagen matrix for homogenization at 4°C until a fine and uniform gel-like substance with a viscosity of 1200 mPa / s is formed.

[0043] Forming freeze-drying: Transfer the gel into a mold for freeze-drying to obtain a sample with a specified structure. There are 10 axial grooves evenly distributed on the surface of the A and B-type samples; after freeze-drying, use a 0.5~0.7mm medical puncture Th...

Embodiment 3

[0045] The bovine cortical bone was cut and pulverized to obtain bone powder with a particle size of 0.05-0.1 mm, which was washed repeatedly to remove blood stains and other sundries. Degreasing, decalcification, and virus inactivation were performed according to the methods in the literature.

[0046] Swelling: soak in 0.3M hydrochloric acid solution at a mass ratio of 1:5 for 2 days, and then wash the swollen bone meal repeatedly with a large amount of purified water until the pH is 6-7. Remove the free water in the bone meal by suction filtration.

[0047] Homogenization: Add purified water at a mass ratio of 1:3, and homogenize at 4°C to form a fine and uniform gel.

[0048] Cross-linking: EDC with a mass fraction of 0.1% was added to the gelatinous collagen matrix, the cross-linking time was 10 hours at 4°C, and the stirring speed was 120 r / min. Then, the purified water was used for repeated dialysis and vibration washing, and the liquid was changed every 8 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com