Preparation method and application of cobaltosic oxide/graphene aerogel composite material

A technology of graphene airgel and cobalt tetroxide, which is applied in cobalt oxide/cobalt hydroxide, material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions can solve the problems of expensive instruments , to achieve the effect of simple operation, large localization area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

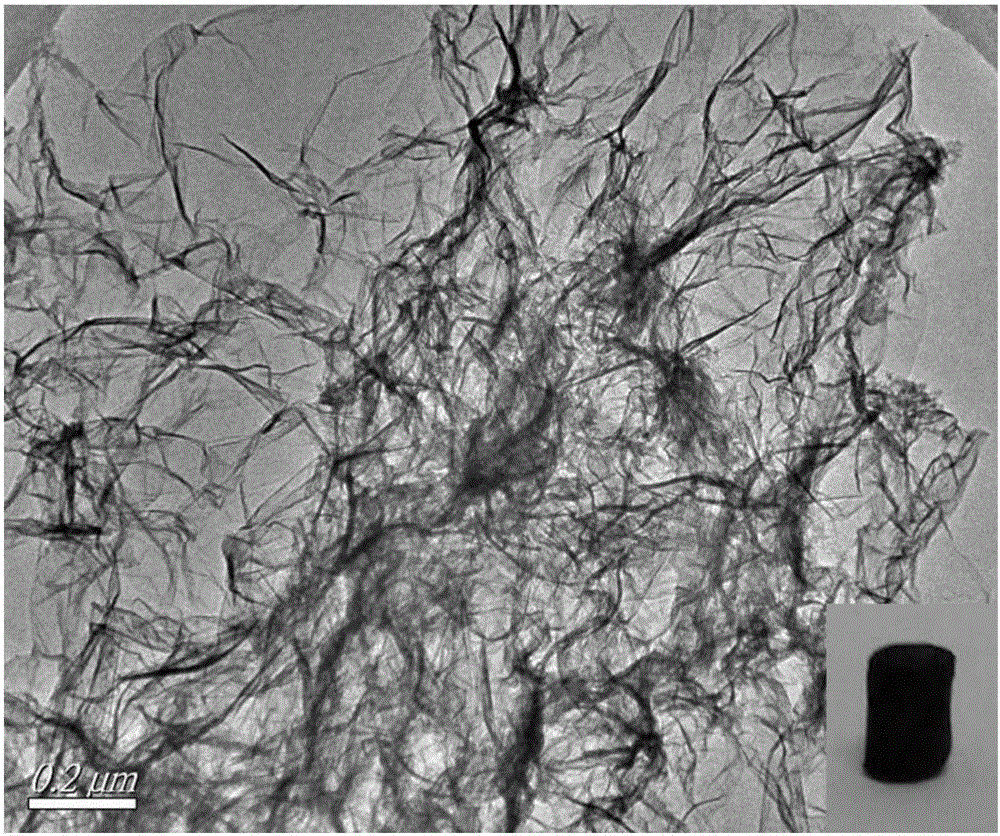

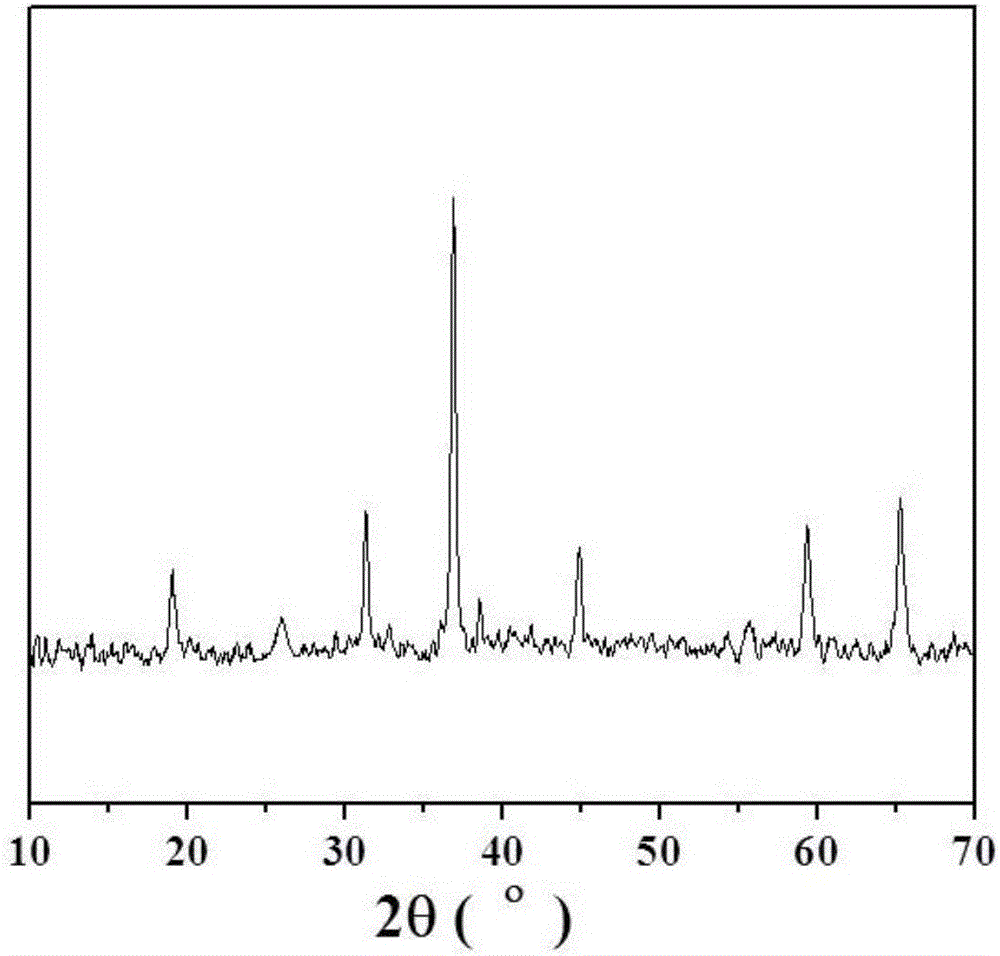

Embodiment 1

[0030] Weigh 50mg of solid graphene oxide and place it in 10mL double-distilled water, and ultrasonicate for 30min to make graphene oxide aqueous solution; weigh 5mg of Co(NO 3 ) 2 dissolved in the graphene oxide aqueous solution, and ultrasonically mixed. Transfer the mixed solution into a 15mL glass bottle, then transfer the 15mL glass bottle to a 20mL polytetrafluorohydrothermal kettle, keep the reaction at 160°C for 24h, and wait for the reaction kettle to drop to room temperature to obtain a cylindrical product; The cylindrical product is pre-frozen at -4°C; the pre-frozen material is placed in a freeze dryer, and freeze-dried at -80°C for 24 hours to obtain the graphene airgel-based composite material GAs / Co 3 o 4 .

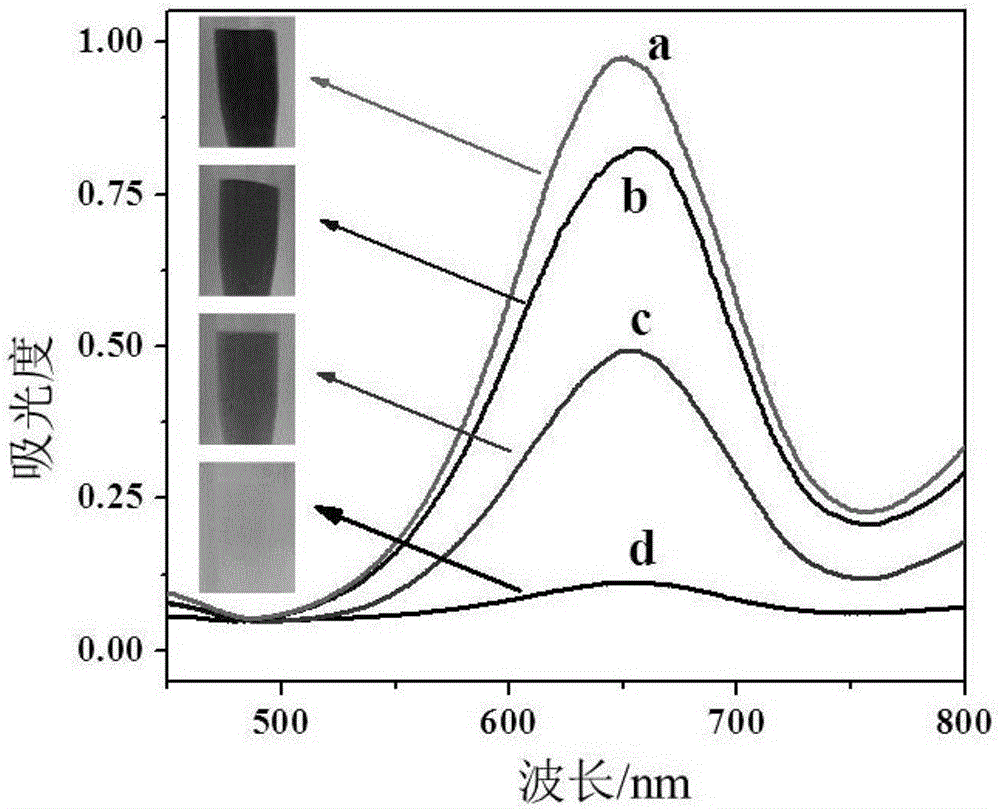

[0031] The sample prepared in this embodiment is used for colorimetric detection of acetylcholine, and the experimental steps are as follows:

[0032] Step 1, H 2 o 2 The corresponding relationship between the concentration and the absorbance of the r...

Embodiment 2

[0036] Weigh 20mg of solid graphene oxide and place it in 20mL double-distilled water, and ultrasonicate for 30min to make graphene oxide aqueous solution; weigh 2mg of Co(NO 3 ) 2 dissolved in the graphene oxide aqueous solution, and ultrasonically mixed. Transfer the mixed solution into a 25mL polytetrafluorohydrothermal kettle, then transfer the polytetrafluorohydrothermal kettle to a 100mL polytetrafluorohydrothermal kettle, keep the reaction at 120°C for 12h, and wait for the reaction kettle to drop to room temperature. Obtain a cylindrical product; pre-freeze the cylindrical product at -2°C; put the pre-frozen material into a freeze dryer, and freeze-dry it at -40°C for 12 hours to obtain a graphene airgel Matrix composite material GAs / Co 3 o 4 .

[0037] The sample prepared in this example was used for colorimetric detection of acetylcholine, and the experimental steps were the same as in Example 1.

Embodiment 3

[0039] Weigh 50mg of solid graphene oxide and place it in 10mL double-distilled water, and ultrasonicate for 30min to make graphene oxide aqueous solution; weigh 100mg of CoCl 2 dissolved in the graphene oxide aqueous solution, and ultrasonically mixed. Transfer the mixed solution into a 15mL glass bottle, then transfer the 15mL glass bottle to a 25mL polytetrafluorohydrothermal kettle, keep the reaction at 160°C for 24h, and wait for the reaction kettle to drop to room temperature to obtain a cylindrical product; The cylindrical product is placed in absolute ethanol for solvent exchange 5 times, and the product after the solvent exchange is transferred to CO 2 Drying in supercritical drying equipment, CO 2 Supercritical drying equipment parameters are: CO 2 Flow 1.5m 3 / h, the temperature is 50°C, the pressure is 16MPa, and the time is 24h. After the drying is completed, the graphene airgel-based composite material GAs / Co 3 o 4 .

[0040] The sample prepared in this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com