High-speed rail ballastless track concrete roadbed slab crack restoration material and preparation and application thereof

A ballastless track and repair material technology, applied in the field of construction engineering, can solve problems such as high cost and complex construction scheme, and achieve the effects of convenient construction, improved chemical medium erosion ability and durability, and super penetration and crystallization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

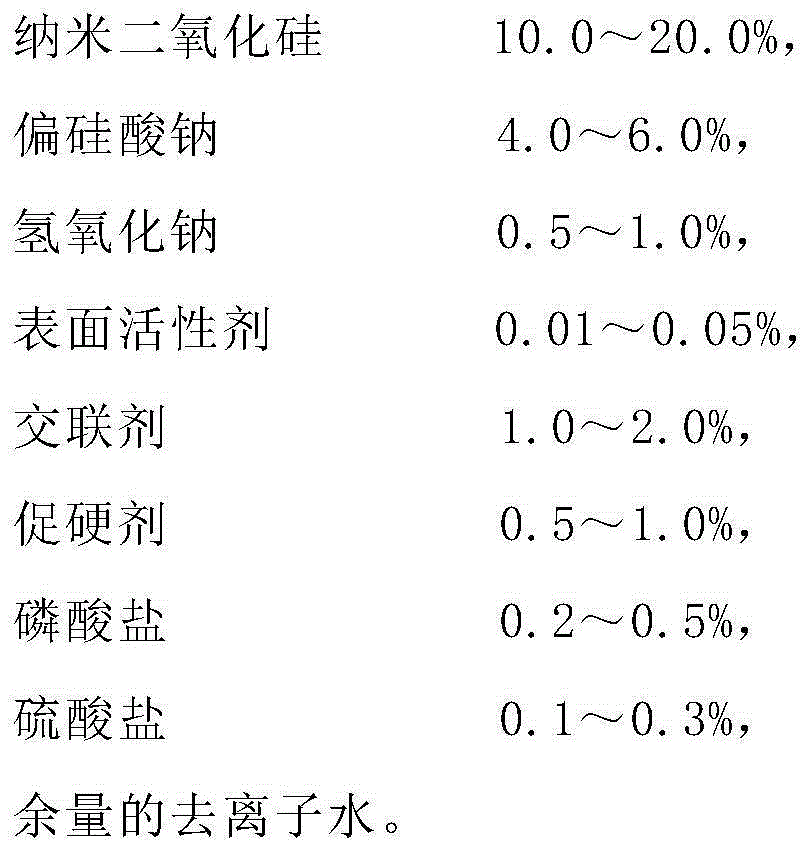

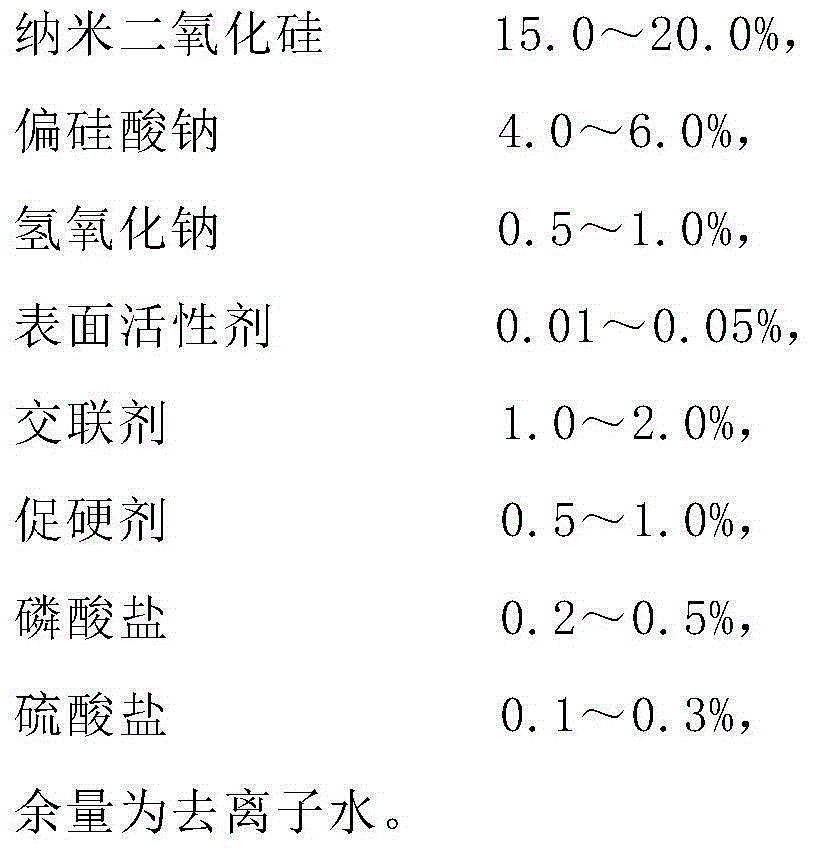

[0029] The composition and weight percentage of the material for repairing and maintaining cracks in the concrete ballast slab of the high-speed rail ballastless track of this embodiment are nano-silica: 15%, sodium metasilicate: 4.0%, sodium hydroxide: 1.0%, sodium fluorosilicate: 0.5 %, aluminum silicate: 2.0%, fluorocarbon surfactant: 0.01, sodium tripolyphosphate: 0.5, sodium sulfate: 0.1, deionized water: 76.89%. Trial preparation is carried out by preparing a 100kg sample.

[0030] The first step, take the deionized water of 76.89kg and place it in the reactor, stir, slowly add 15kg nano-silicon dioxide, stir for 15 minutes, then slowly add 4.0kg sodium metasilicate and 1.0kg sodium hydroxide, this time Seal the reactor and maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 100 ° C, and continue stirring for 15 minutes; stand for observation for 2 hours, remove the pressure and temperature after it is clear, and keep stirring until it ...

Embodiment 2

[0034] The composition and weight percentage of the material for repairing and maintaining cracks in the concrete ballast slab of the high-speed rail ballastless track of this embodiment are nano-silica: 20%, sodium metasilicate: 6.0%, sodium hydroxide: 0.5%, calcium fluorosilicate: 1.0 %, aluminum silicate: 1.5%, fluorocarbon surfactant: 0.05%, sodium tripolyphosphate: 0.2%, sodium sulfate: 0.3%, deionized water: 70.45%. Trial preparation is carried out by preparing a 100kg sample.

[0035] The first step, take 70.45kg of deionized water and place it in the reactor, stir, slowly add 20kg of nano-silicon dioxide, stir for 15 minutes, then slowly add 6.0kg of sodium metasilicate and 0.5kg of sodium hydroxide, this time Seal the reactor and maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 110 ℃, continue stirring for 10 minutes; stand and observe for 2 hours, remove the pressure and temperature after it is clear, and keep stirring until it c...

Embodiment 3

[0039] The composition and weight percentage of the high-speed rail ballastless track concrete ballast slab crack repair and maintenance material in this embodiment are nano-silica: 17.5%, sodium metasilicate: 5.0%, sodium hydroxide: 0.8%, ferric chloride: 1.0 %, aluminum silicate: 1.5%, fluorocarbon surfactant: 0.03%, sodium tripolyphosphate: 0.3%, sodium sulfate: 0.2%, deionized water: 73.67%. Trial preparation is carried out by preparing a 100kg sample.

[0040] The first step, take the deionized water of 73.67kg and place it in the reactor, stir, slowly add 17.5kg nano-silicon dioxide, stir for 15 minutes, then slowly add 5.0kg sodium metasilicate and 0.8kg sodium hydroxide, this Seal the reactor and maintain the working pressure of the reactor at 21g / cm 2 , the working temperature is 100 ℃, continue to stir for 10 minutes; stand and observe for 1.5 hours, remove the pressure and temperature after it is clear, and keep stirring until it cools to room temperature to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com