Seawater resistant vinyl ester composite material and preparation method thereof

A vinyl ester and composite material technology, applied in the field of composite materials, can solve the problems of shortened service life, decreased performance, poor seawater resistance, etc., and achieves the effects of long service life, good mechanical properties, and improved seawater resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

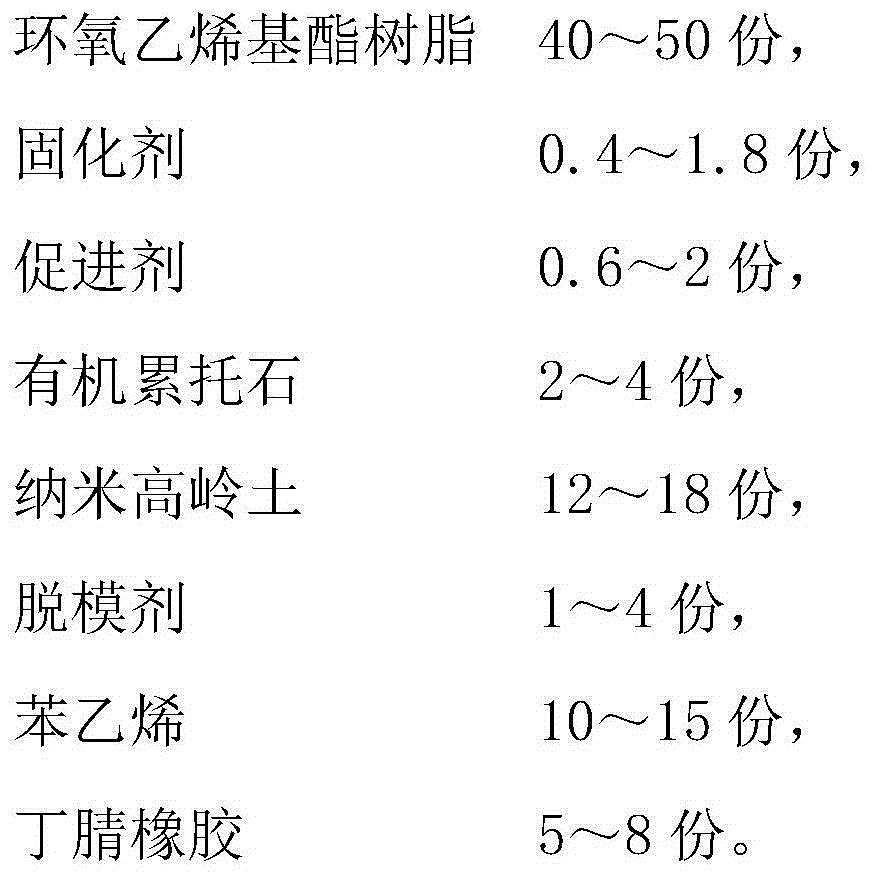

[0027] A kind of seawater resistant vinyl ester composite material, its parts by weight consist of: 40 parts of epoxy vinyl ester resin, 0.5 part of cumene hydroperoxide, 0.8 part of cobalt isooctanoate, 4 parts of organic rectorite, 16 parts of nano kaolin parts, 2 parts of polyethylene glycol, 15 parts of styrene, and 8 parts of nitrile rubber, wherein the interlayer distance of organic rectorite is 2.5-2.6nm.

[0028] The steps of its preparation method are as follows:

[0029] (1) Add rectorite to distilled water and place it in a constant temperature water bath with a temperature of 85°C for ultrasonic oscillation. After 6 minutes, add dodecyl dimethyl benzyl ammonium chloride, rectorite and dodecyl dimethyl The weight ratio of benzyl ammonium chloride is 18:1, continue ultrasonic oscillation for 25 minutes, let stand at room temperature for 20 hours, centrifuge, wash, dry, grind, and sieve to obtain organic rectorite for subsequent use;

[0030] (2) placing the nano-kao...

Embodiment 2

[0033] A kind of seawater resistant vinyl ester composite material, its parts by weight consist of: 45 parts of epoxy vinyl ester resin, 0.9 part of cumene hydroperoxide, 2 parts of cobalt isooctanoate, 3 parts of organic rectorite, 18 parts of nano kaolin 1 part, 1 part of polyethylene glycol, 12 parts of styrene, 5 parts of nitrile rubber, wherein the interlayer distance of organic rectorite is 2.5-2.6nm.

[0034] Its preparation method is the same as embodiment one.

Embodiment 3

[0036] A kind of seawater resistant vinyl ester composite material, its parts by weight consist of: 44 parts of epoxy vinyl ester resin, 0.4 part of cumene hydroperoxide, 1 part of cobalt isooctanoate, 3.5 parts of organic rectorite, 17 parts of nano kaolin parts, 4 parts of polyethylene glycol, 14 parts of styrene, and 7 parts of nitrile rubber, wherein the interlayer distance of organic rectorite is 2.5-2.6nm.

[0037] Its preparation method is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com