Method for producing lactic acid bacteria agent and bacteriocin by using salted vegetable wastewater

A technology of salted vegetables and lactic acid bacteria agents, which is applied in the field of production of lactic acid bacteria agents and bacteriocins, can solve the problems of complex material components, low added value of products, and unstable quality of salted vegetable concentrates, and achieve reduction in emissions and treatment Difficulty, low cost, enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

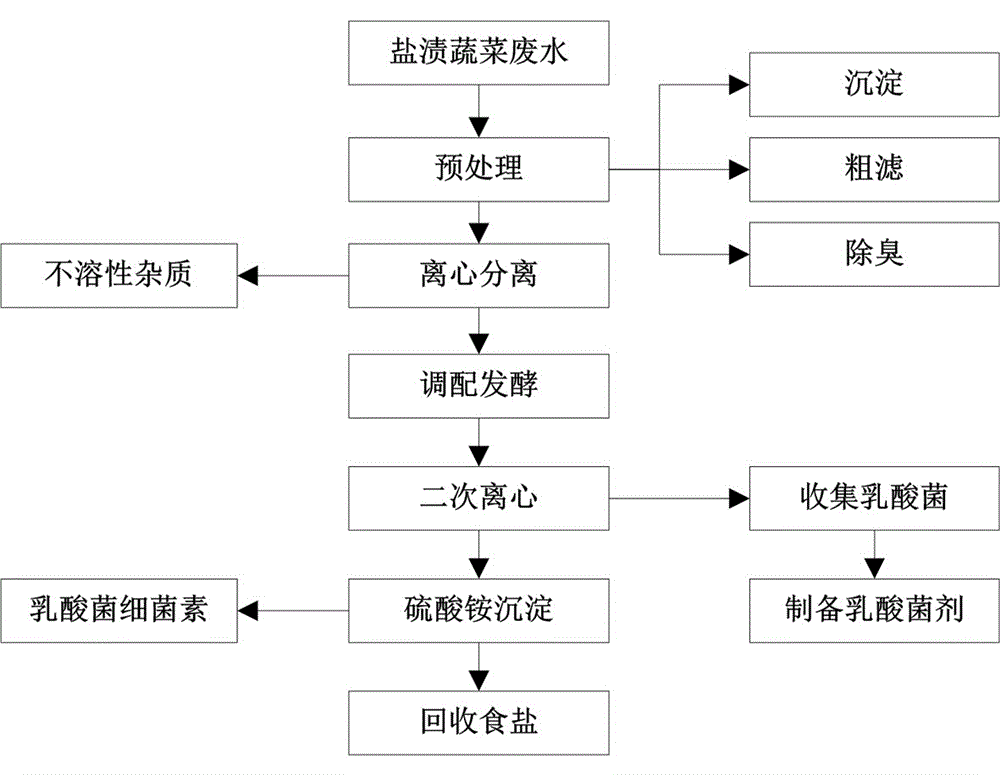

[0025] Embodiment 1: a kind of method utilizing salted vegetables waste water to produce lactic acid bacteria agent and bacteriocin, it comprises the following steps:

[0026] S1. Collect the fermented and mature salted vegetable waste water in the adjustment sedimentation tank, settle for 24 hours, and then carry out coarse filtration through the filter screen at the bottom of the adjustment sedimentation tank. Insoluble impurities such as vegetable leaves, vegetable dregs, sand and stones are deodorized by activated carbon to obtain a salted fermentation cell suspension. The salinity of the salted vegetable wastewater is 1%, and the reducing sugar in terms of glucose is 0.01%, centrifuged at 4000rpm After 9 minutes, the total nitrogen content in terms of protein in the aqueous solution is 3%, the non-salt soluble solid content is 0.01%, and the sensory requirements are no rancidity, no peculiar smell, no blackening, and no mildew floating film;

[0027] S2. Centrifuge the sa...

Embodiment 2

[0033] Embodiment 2: a kind of method utilizing salted vegetable waste water to produce lactic acid bacteria agent and bacteriocin, it comprises the following steps:

[0034] S1. Collect the fermented and mature salted vegetable waste water in the adjustment sedimentation tank, settle for 30h, and then carry out coarse filtration through the filter screen at the bottom of the adjustment sedimentation tank. Insoluble impurities such as vegetable leaves, vegetable dregs, sand and stones are deodorized by activated carbon to obtain a salted fermentation cell suspension. The salinity of the salted vegetable wastewater is 3%, and the reducing sugar in terms of glucose is 3%, centrifuged at 4000rpm After 10 minutes, the total nitrogen content in terms of protein in the aqueous solution is 0.01%, the non-salt soluble solid content is 3%, and the sensory requirements are no rancidity, no peculiar smell, no blackening, and no mildew floating film;

[0035] S2. Centrifuge the salted fer...

Embodiment 3

[0041] Embodiment 3: a kind of method utilizing salted vegetable waste water to produce lactic acid bacteria agent and bacteriocin, it comprises the following steps:

[0042] S1. Collect the fermented and mature salted vegetable waste water in the adjustment sedimentation tank, settle for 36 hours, and then carry out coarse filtration through the filter screen at the bottom of the adjustment sedimentation tank. Insoluble impurities such as vegetable leaves, vegetable dregs, sand and stones are deodorized by activated carbon to obtain a salted fermentation cell suspension. The salinity of the salted vegetable waste water is 5%, the reducing sugar in terms of glucose is 5%, and centrifuged at 4000rpm After 11 minutes, the total nitrogen content in terms of protein in the aqueous solution is 7%, the non-salt soluble solid content is 5%, and the sensory requirements are no rancidity, no peculiar smell, no blackening, and no mildew floating film;

[0043] S2. Centrifuge the salted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com