Backside-illuminated image sensor wafer level packaging process and packaging structure

An image sensor, wafer-level packaging technology, applied in radiation control devices and other directions, can solve the problems of poor physical support, residual glue in the photosensitive area, limited photon absorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A wafer-level packaging process for a back-illuminated image sensor of the present invention comprises the following steps:

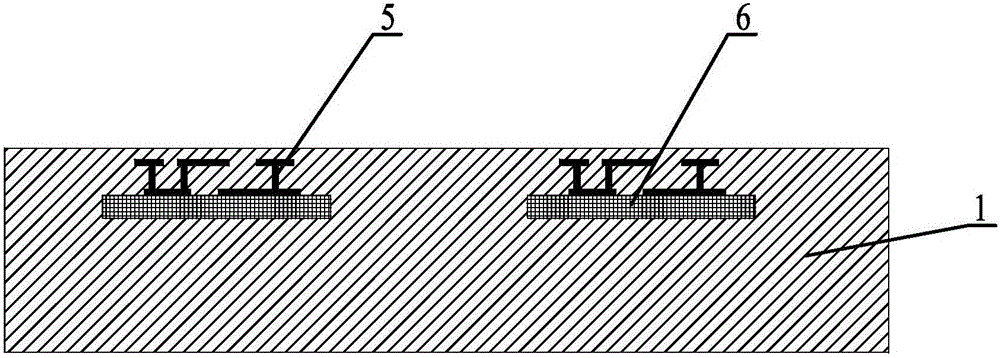

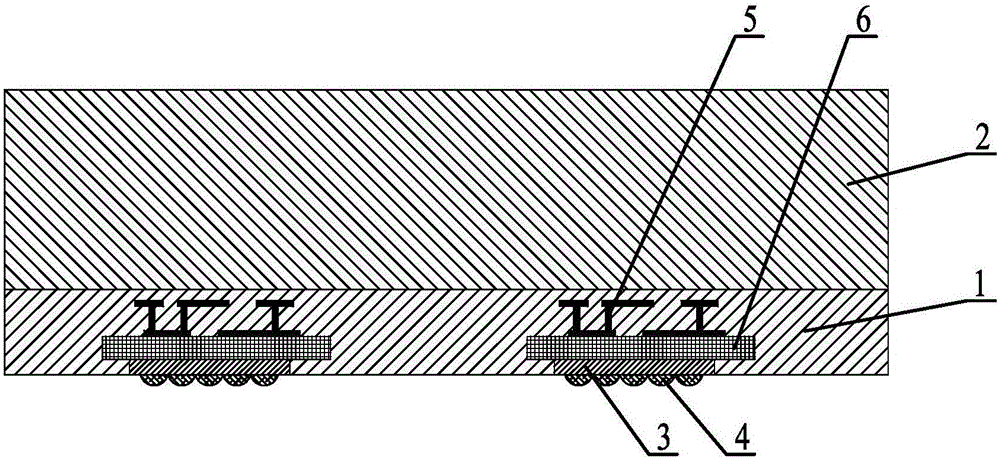

[0037] a. Take the CIS wafer 1 on which the leads 5 and the image sensor 6 have been made on the front side. The thickness of the CIS wafer 1 is 50 μm, and the thickness of the CIS wafer 1 is bonded by a conventional silicon-silicon bonding method A 200um load wafer 2 is supported by the load wafer 2 to thin the back of the CIS wafer 1, and a filter 3 and a microlens 4 are placed on the back of the thinned CIS wafer 1, such as figure 1 shown;

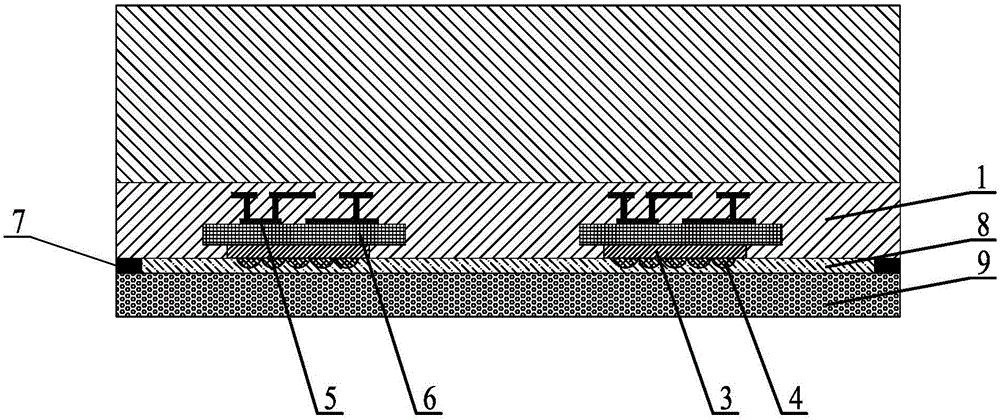

[0038] b. The edge position of the back side of the CIS wafer 1 is covered by the first adhesive glue 7 in a coating method. The material of the first adhesive glue 7 is benzocyclobutene. The backside edge of wafer 1 forms a closed ring, the width of the first bonding glue 7 is 1mm and the thickness of the first bonding glue is 10nm, coats with the second bonding glue 8 in this closed ring, the second Th...

Embodiment 2

[0042] A wafer-level packaging process for a back-illuminated image sensor of the present invention comprises the following steps:

[0043] a. Take the CIS wafer 1 on which the leads 5 and the image sensor 6 have been made on the front side. The thickness of the CIS wafer 1 is 100 μm, and the thickness of the CIS wafer 1 is bonded by conventional silicon-oxygen bonding method A 300um load wafer 2 is supported by the load wafer 2 to thin the back of the CIS wafer 1, and a filter 3 and a microlens 4 are placed on the back of the thinned CIS wafer 1, such as figure 1 shown;

[0044] b. Cover the edge position of the back side of the CIS wafer 1 by spraying the first adhesive glue 7, the material of the first adhesive glue 7 is thermoplastic epoxy resin, and the first adhesive glue 7 is placed on the CIS wafer The back edge of 1 forms a closed ring, the width of the first bonding glue is 2mm and the thickness of the first bonding glue is 1um, and the second bonding glue 8 is used...

Embodiment 3

[0048] A wafer-level packaging process for a back-illuminated image sensor of the present invention comprises the following steps:

[0049] a. Take the CIS wafer 1 on which the leads 5 and the image sensor 6 have been made on the front, the thickness of the CIS wafer 1 is 150 μm, and the thickness of the CIS wafer 1 is bonded by conventional oxygen-oxygen bonding method A 400 um load wafer 2 is supported by the load wafer 2 to thin the back of the CIS wafer 1, and a filter 3 and a microlens 4 are placed on the back of the thinned CIS wafer 1, such as figure 1 shown;

[0050] b. The edge position on the back side of the CIS wafer 1 is covered by the first adhesive glue 7 in a film-pasting manner. The material of the first adhesive glue 7 is UV epoxy resin, and the first adhesive glue 7 is placed on the CIS wafer. The back edge of 1 forms a closed ring, the width of the first adhesive glue is 3mm and the thickness of the first adhesive glue is 100um, and the second adhesive glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com