Method for preparing quantum dot photodetection array device based on ink-jet printing technology

An inkjet printing and light detection technology, which is applied in the manufacturing of semiconductor devices, electrical components, and final products, etc., can solve the problems of wasting materials and complicated preparation processes, and achieves strong controllability, simple and convenient process operation, and good recovery. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

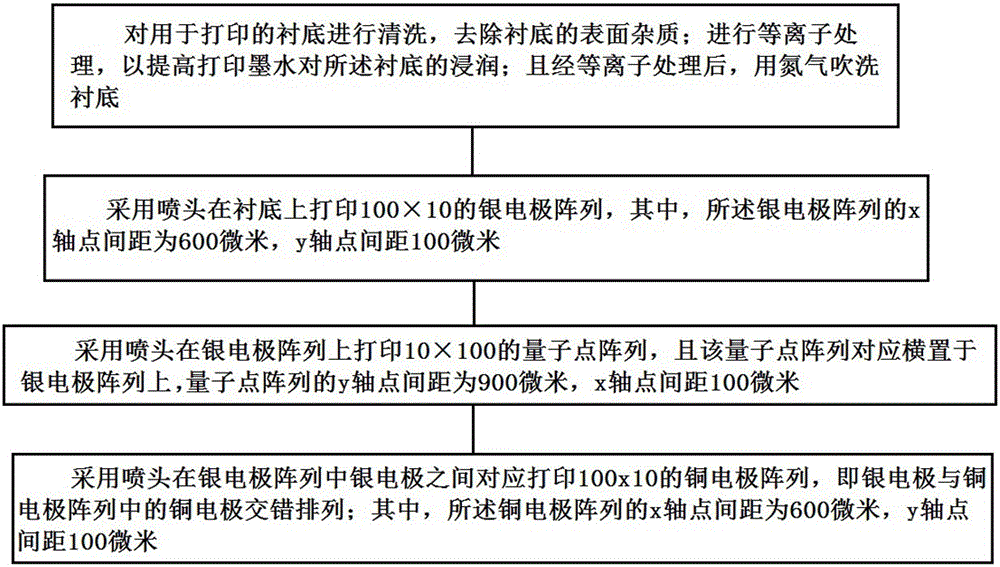

Method used

Image

Examples

Embodiment 1

[0045] Step S1: ultrasonically clean the common PET substrate used for printing with acetone, ethanol and deionized water for 15 minutes to remove surface impurities of the common PET substrate; perform plasma treatment for 10 minutes to improve the printing ink’s effect on the common PET substrate. Wetting of the substrate; and after plasma treatment, purging the common PET substrate with nitrogen; in the present embodiment, the common PET substrate is plasma treated and soaked in chloroform to improve The surface roughness of the common PET substrate.

[0046] Step S2: using an inkjet printer jetlab2 to print a 100×10 silver electrode array on the ordinary PET substrate with an 80-micron nozzle, and heat-treat the silver electrodes at a temperature of 80 degrees Celsius after printing, wherein the silver electrode array The x-axis point spacing is 600 microns, the y-axis point spacing is 100 microns, the thickness of the silver electrode is 50 nanometers, and the pri...

Embodiment 2

[0051] Step S1: ultrasonically clean the ordinary PET substrate used for printing with acetone, ethanol and deionized water for 15 minutes to remove surface impurities of the ordinary PET substrate; perform plasma treatment for 10 minutes to improve the printing ink's resistance to the ordinary PET substrate. Wetting of the PET substrate; and after the plasma treatment, the ordinary PET substrate is purged with nitrogen; in this embodiment, the ordinary PET substrate is plasma treated and soaked in chloroform for Improve the surface roughness of the common PET substrate.

[0052] Step S2: using an inkjet printer jetlab2 to print a 100×10 silver electrode array on the ordinary PET substrate with an 80-micron nozzle, and heat-treat the silver electrodes at a temperature of 80 degrees Celsius after printing, wherein the silver electrode array The x-axis point spacing is 600 microns, the y-axis point spacing is 100 microns, the thickness of the silver electrode is 50 na...

Embodiment 3

[0057] Step S1: ultrasonically clean the common glass substrate used for printing with acetone, ethanol and deionized water for 15 min to remove the surface impurities of the common glass substrate; perform plasma treatment for 10 min to improve the printing ink’s resistance to the common glass substrate. Wetting of the glass substrate; and after the plasma treatment, the ordinary glass substrate is purged with nitrogen; in this embodiment, the ordinary glass substrate is subjected to plasma treatment and soaked in chloroform for Improve the surface roughness of the common glass substrate.

[0058] Step S2: using an inkjet printer jetlab2 to print a 100×10 silver electrode array on the ordinary glass substrate with an 80-micron nozzle, and heat-treat the silver electrodes at a temperature of 80 degrees Celsius after printing, wherein the silver electrode array The x-axis point spacing is 600 microns, the y-axis point spacing is 100 microns, the thickness of the silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com