Preparation method of multi-element polyphase composite lithium ion battery negative material

A composite material, ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large irreversible capacity loss of metal oxides, inability to commercialize nanomaterials, and complicated preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

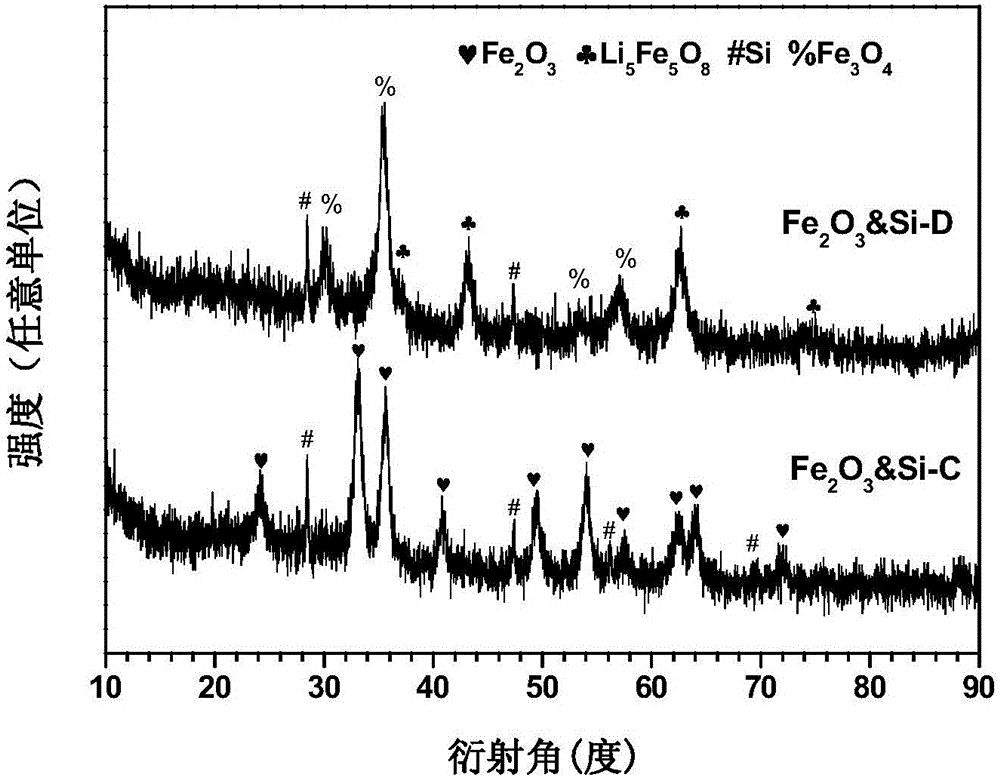

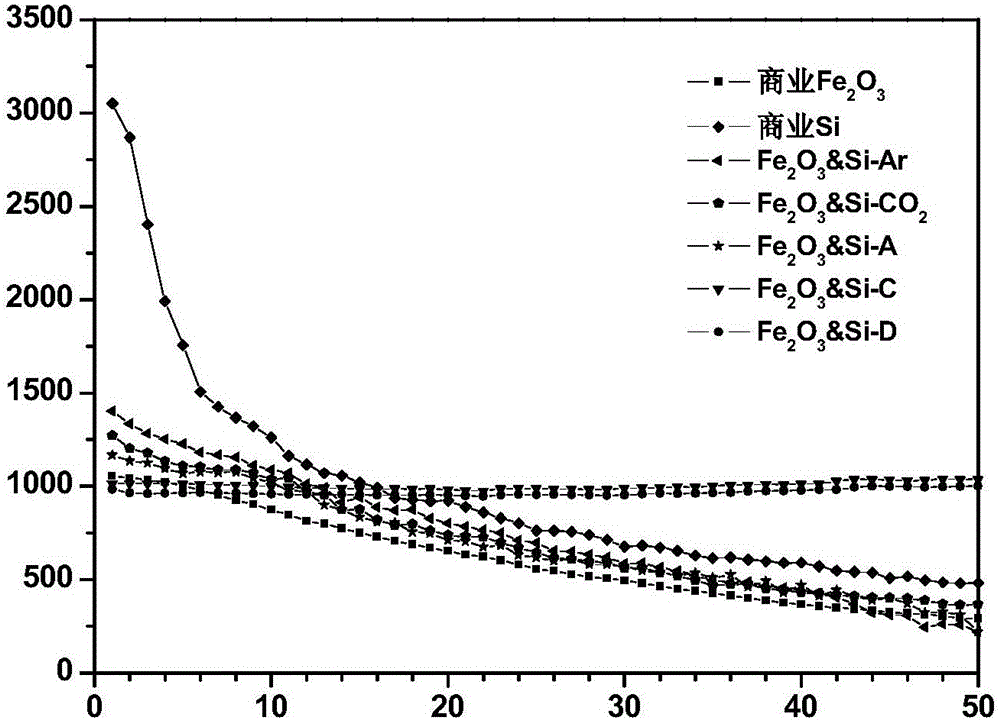

[0066] Commercial Fe 2 o 3 , silicon simple substance, LiH molar ratio is 1:0.33:0.67. In an argon atmosphere glove box, weigh commercial Fe 2 o 3 5g, 0.35g of simple silicon, and 0.17g of LiH powder were put into a ball mill jar, the ball-to-material ratio (mass ratio) was 20:1, and the grinding balls were stainless steel balls. Then put the ball mill jar on the planetary ball mill, and ball mill it for 2 hours at a speed of 200 rpm. The obtained sample is taken out in the glove box of argon atmosphere, and marked as sample Fe 2 o 3 &Si-A.

[0067] Take the above sample Fe 2 o 3 &Si-A 2.5g, heat and dehydrogenate in a vacuum atmosphere, the heating rate is 5 degrees Celsius / min, the heating temperature is 530 degrees Celsius, keep warm for 4 hours, in the heat preservation stage, vacuumize the system once every 0.5 hours, and then cool down to room temperature . A completely dehydrogenated product was obtained, labeled as sample Fe 2 o 3 &Si-B.

[0068] Take sampl...

Embodiment 2

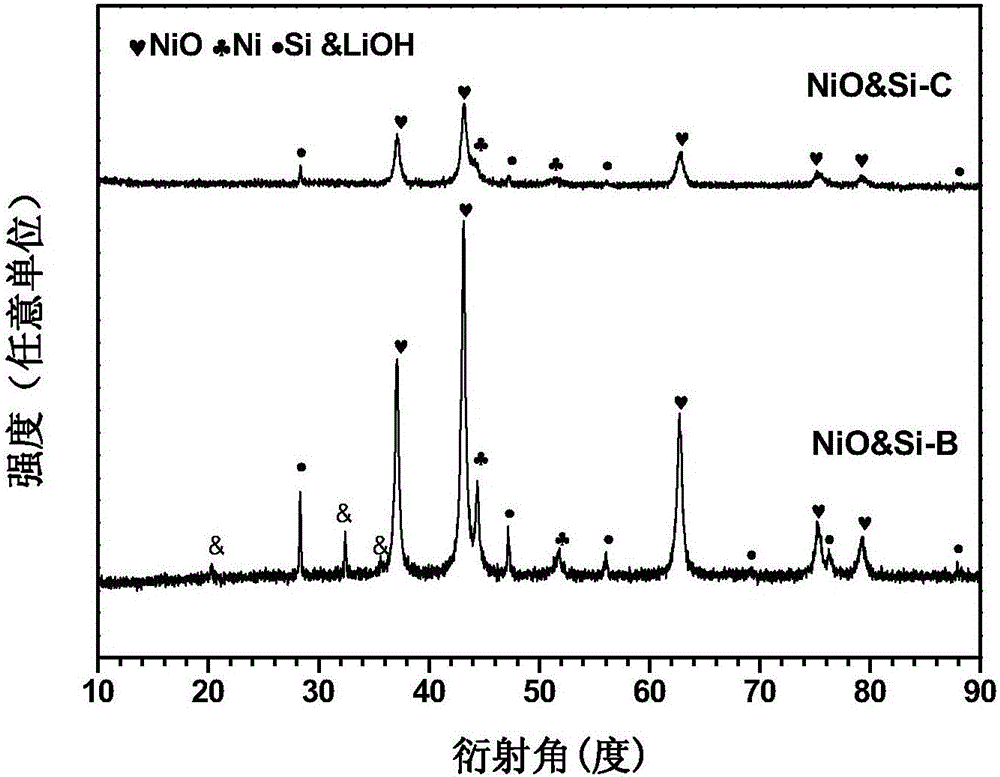

[0077] The molar ratio of commercial NiO, silicon element, and LiH is 1:0.2:0.3. In an argon atmosphere glove box, 5 g of commercial NiO, 0.35 g of silicon element, and 0.17 g of LiH powder were weighed and put into a ball mill jar with a ball-to-material ratio (mass ratio) of 20:1, and the balls were stainless steel balls. Then the ball mill jar was placed on a planetary ball mill, and ball milled at a speed of 200 rpm for 2 hours, and the obtained sample was taken out in an argon atmosphere glove box, and marked as sample NiO&Si-A.

[0078] Take 2.5g of the above sample NiO&Si-A, heat and dehydrogenate in a vacuum atmosphere, the heating rate is 5 degrees Celsius / min, the heating temperature is 270 degrees Celsius, and keep warm for 0.5 hours. During the heat preservation stage, the system is evacuated once every 0.1 hours, and then Cool to room temperature. A completely dehydrogenated product was obtained, labeled as sample NiO&Si-B.

[0079] Take 1g of sample NiO&Si-B an...

Embodiment 3

[0088] The molar ratio of commercial CoO, simple silicon, and LiH is 1:0.2:0.3. In the argon atmosphere glove box, ball mill tanks A and B were filled with 5g of commercial CoO, 0.35g of silicon element, 0.17g of LiH powder, the ball-to-material ratio (mass ratio) was 20:1, and the grinding balls were stainless steel balls. After the ball mill tank B is evacuated, it is filled with 3bar CO 2 gas, and then put the ball mill jars A and B together on the planetary ball mill, and ball milled at a speed of 400 rpm for 12 hours, and the obtained samples were taken out in the glove box with an argon atmosphere, labeled as samples CoO&Si-A and CoO&Si-B .

[0089] Take 2.5g of the above sample CoO&Si-B, and anneal in a vacuum atmosphere. The heating rate is 5 degrees Celsius / min, the heating temperature is 350 degrees Celsius, and the temperature is kept for 4 hours. During the heat preservation stage, the system is evacuated every 0.5 hours, and then cooled to room temperature. A c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com