A kind of lithium-ion battery electrolyte and battery preparation method

A lithium-ion battery and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve problems such as the inability to reduce moisture, and achieve the effects of reducing moisture, improving performance, and optimizing process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

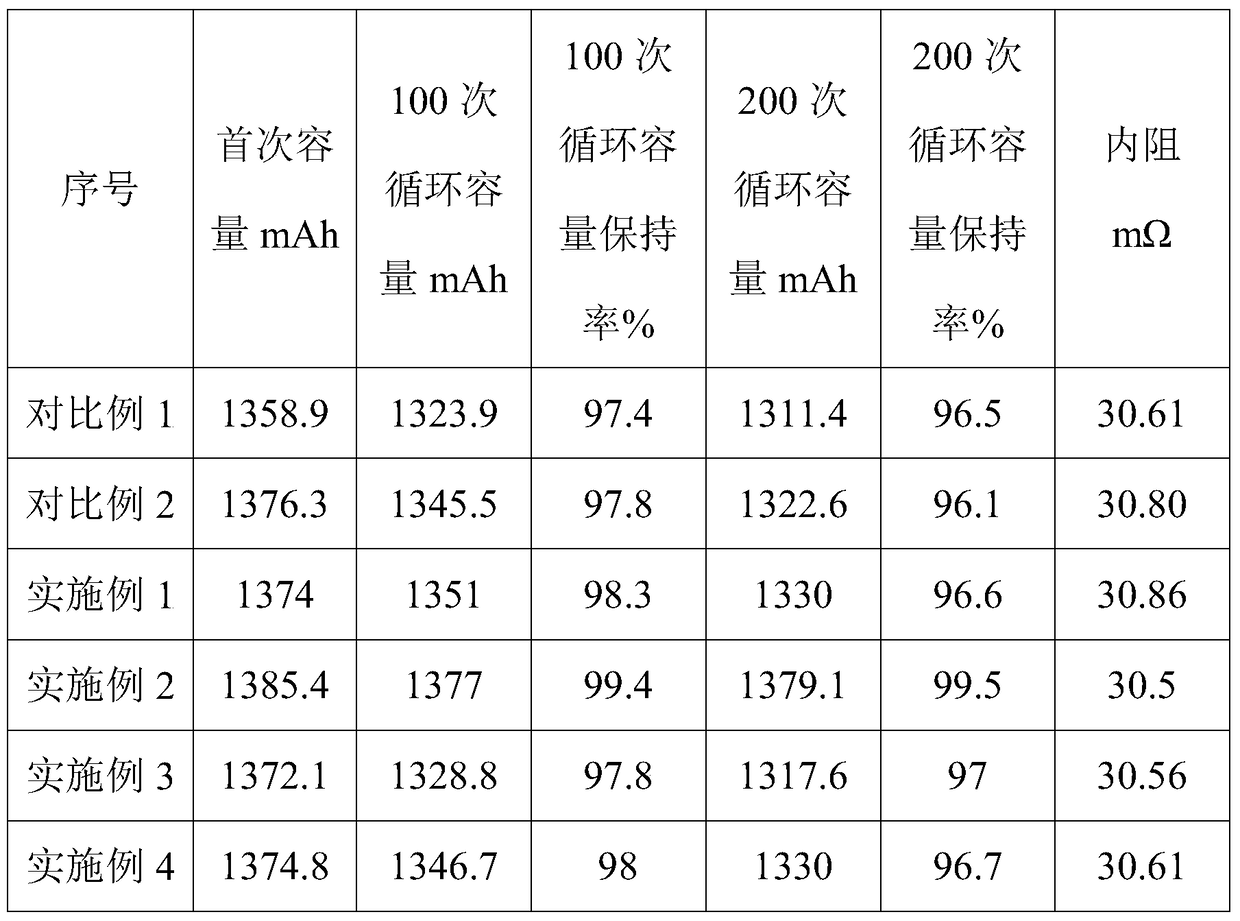

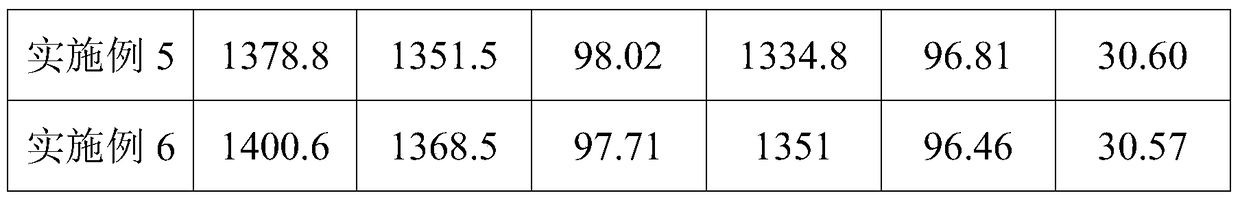

Examples

preparation example Construction

[0030] The present invention also provides a lithium-ion battery preparation method, which includes the following steps in sequence, active material batching, coating, pole piece preparation, pole piece baking, winding, core winding into the shell, welding, and pre-vacuum baking. The vacuum drying temperature before the above is 80±5℃, the vacuum degree is -0.095~0.10Mpa, the atmosphere inside the vacuum oven is replaced with nitrogen every 1-2H, and the baking time is 2~48h; inject the solvent of the additive, and turn the liquid injection port upside down. Stand still for 1-5 minutes, set the vacuum degree -0.05~-0.1Mpa to extract the solvent injected into the battery, and then perform post-vacuum baking. The drying temperature of the post-vacuum baking described above is 80±5°C, and the vacuum degree is -0.095 ~0.10Mpa, replace the atmosphere inside the vacuum oven with nitrogen every 1-2H, the baking time is 2~48h, the sum of the pre-vacuum baking time and the post-vacuum b...

Embodiment 1

[0034]A method for preparing a lithium-ion battery, comprising the steps of batching active materials, coating, making pole pieces, baking pole pieces, winding, winding cores into shells, welding, pre-vacuum baking, and pre-vacuum drying The temperature is 80°C, the vacuum degree is -0.095~0.10Mpa, the atmosphere inside the vacuum oven is replaced with nitrogen every 1-2H, and the baking time is 3h; the solvent dimethyl carbonate (DEC) is injected into the additive, the liquid injection port is inverted, and the To 1-5min, set the vacuum degree -0.05 ~ -0.1Mpa, so that the solvent dimethyl carbonate (DEC) injected into the battery is drawn out, and then the post-vacuum baking is carried out. The drying temperature of the post-vacuum baking is 80°C, vacuum The temperature is -0.095~0.10Mpa, the atmosphere in the vacuum oven is replaced with nitrogen every 1-2H, the baking time is 24h, the sum of the pre-vacuum baking time and the post-vacuum baking time is 27h, and then electrol...

Embodiment 2

[0036] The difference from Example 1 is: the solvent for injecting the additive is ethyl methyl carbonate (EMC) solution to clean the lithium-ion battery, and the injected electrolyte includes solvent, lithium salt and additive; the solvent is dimethyl carbonate 50wt%, carbonic acid Diethyl ester 20wt% and ethyl methyl carbonate 25wt%. The lithium salt is LiPF 6 , and its concentration is 1.0mol / L; the additives include chromium complex coupling agent 1wt%, titanate coupling agent 1wt%, vinylene carbonate 1wt%, 1,3-propane sultone 2wt% %. Others are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com