Stabilizer for hydrogen peroxide disinfectant in aseptic packaging equipment for dairy beverages

A packaging equipment, hydrogen peroxide technology, applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of incomplete disinfection of packaging materials, poor stability, difficult cleaning and removal, etc., to avoid excessive concentration. The effect of rapid rise, lower decomposition rate and lower surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A stabilizer for hydrogen peroxide used for packaging and disinfection in dairy beverage aseptic packaging equipment, which is composed of the following raw materials in weight percentage: 20% of nitrilo trimethylene phosphonic acid, 2% of trehalose, 0.2% of pentaerythritol monooleate %, N-acylglutamic acid 0.2%, pure water 77.6%.

[0027] Its preparation method is: adding trehalose, pentaerythritol monooleate and N-acyl glutamic acid into nitrilo trimethylene phosphonic acid in sequence, after mixing evenly, adding ultrapure water to meet the ratio requirements, stirring for 2 hours, that is Hydrogen peroxide stabilizer.

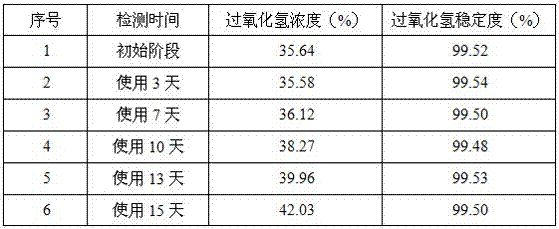

[0028] The stabilizer is directly mixed with 35% hydrogen peroxide at room temperature, and the concentration of the stabilizer in the hydrogen peroxide solution is 0.005%. This hydrogen peroxide solution is used for the sterilization of the packaging in the dairy beverage aseptic packaging equipment, and the trial production is carried out many tim...

Embodiment 2

[0033] A stabilizer for hydrogen peroxide used for packaging and disinfection in dairy beverage aseptic packaging equipment, which is composed of the following raw materials in percentage by weight: 25% diethylenetriaminepentamethylenephosphonic acid, 5% glycerol; Alkenyl succinic acid 0.1%, sodium diisooctyl sulfosuccinate 0.5%, pure water 69.4%.

[0034] Its preparation method is: add glycerol, pentaerythritol monooleate and sodium dioctyl sulfosuccinate to diethylene triamine pentamethylene phosphonic acid in sequence, after mixing evenly, add ultrapure water to Proportion requirements, stirring treatment for 3 hours, that is, the hydrogen peroxide stabilizer.

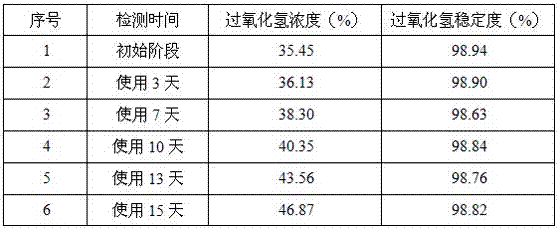

[0035] The stabilizer is directly mixed with 35% hydrogen peroxide at room temperature, and the concentration of the stabilizer in the hydrogen peroxide solution is 0.003%. The hydrogen peroxide solution was used in a small test to simulate the sterilization of packaging in aseptic packaging equipment for dairy bev...

Embodiment 3

[0039] A stabilizer for hydrogen peroxide for packaging and disinfection in dairy beverage aseptic packaging equipment, which is composed of the following raw materials in weight percentage: 30% citric acid, 8% polyacrylamide, 1% alkenyl succinic acid, and sorbic acid Alcohol polyoxyethylene ether monostearate 1%, pure water 60%.

[0040] The preparation method is as follows: add trehalose, alkenyl succinic acid and sorbitan polyoxyethylene ether monostearate in sequence to citric acid, after mixing evenly, add ultrapure water to meet the ratio requirements, and stir for 2.5 hours , that is, hydrogen peroxide stabilizer.

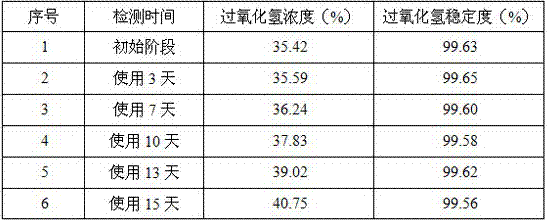

[0041] The stabilizer is directly mixed with 35% hydrogen peroxide at room temperature, and the concentration of the stabilizer in the hydrogen peroxide solution is 0.001%. The hydrogen peroxide solution was used in a small test to simulate the sterilization of packaging in aseptic packaging equipment for dairy beverages. Put the hydrogen peroxide solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com