Multilayer core-shell structured Au@SiO2@Ag@SiO2 nano composite material and preparation method therefor

A nanocomposite material and multi-layer core-shell structure technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve problems such as lattice defects, and achieve strong Raman signals, high detection sensitivity, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

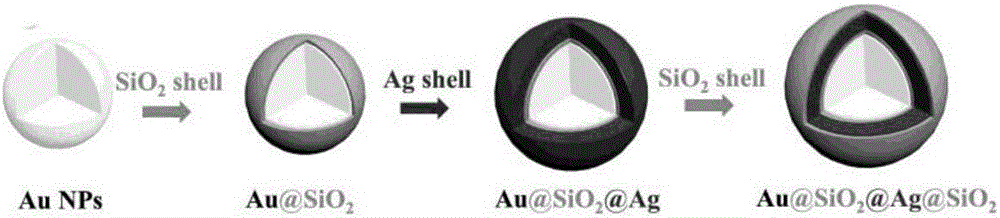

[0025] The multilayer core-shell structure AuSiO provided by the present invention 2 AgSiO 2 The preparation method of nanocomposite material specifically comprises the following steps:

[0026] The first step, AuSiO 2 Preparation of core-shell nanomaterials:

[0027] Get 20~60ml 0.01% (mass percentage) chloroauric acid solution and when heated to boiling, add 0.1~0.5ml 1wt% sodium citrate solution and react, the solution changes from light yellow to slightly blue and then becomes transparent brownish red, wait After the reaction was complete, the heating was stopped and cooled to room temperature naturally. Then add aminosilane solution, stir at room temperature, then add 0.5~4ml 0.04M sodium silicate solution, stir at room temperature, transfer to 90~96°C oil bath for reaction, stop heating and cool down naturally to obtain AuSiO 2 Core-shell nanomaterials, such as figure 1 shown.

[0028] The second step, AuSiO 2 AgSiO 2 Preparation of core-shell nanomaterials:

[...

Embodiment 1

[0032] The first step, AuSiO 2 Preparation of core-shell nanomaterials:

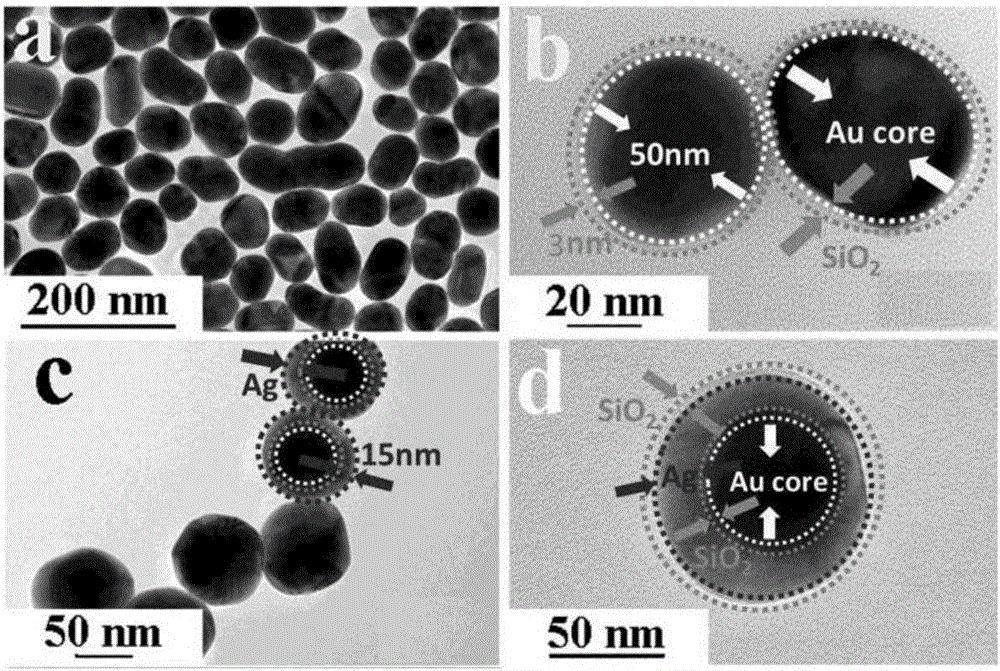

[0033] Take 30ml 0.01wt% chloroauric acid solution and heat it to boiling, add 0.2ml 1wt% sodium citrate solution and react for 20 minutes, the solution turns from light yellow to slightly blue and then transparent brown red, after the reaction is complete Turn off the heat and cool to room temperature naturally. Then add 0.4ml 1mM aminosilane solution successively, stir at room temperature for 10min, then add 2ml 0.04M sodium silicate solution, stir at room temperature for 5min, then transfer to 93°C oil bath for reaction for 1h, turn off the heating and cool down naturally to obtain SiO 2 AuSiO with a shell thickness of 3nm 2 Core-shell nanomaterials.

[0034] The second step, AuSiO 2 AgSiO 2 Preparation of core-shell nanomaterials:

[0035] AuSiO 2 AgSiO 2 Core-shell nanomaterials: under dark conditions, in the above AuSiO 2 Add 540ul of 0.1M ascorbic acid, 135ul of 0.1M silver nitrate and 67...

Embodiment 2

[0038] Change the amount of sodium silicate solution into 0.5ml 0.04M sodium silicate solution in the first step of embodiment 1 to prepare SiO 2 AuSiO with a shell thickness of 1nm 2 Core-shell structure nanomaterial, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com