A kind of method for preparing bowtie-shaped bismuth oxyfluoride photocatalyst and catalyst application

A junctional bismuth oxyfluoride, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, bismuth compounds, etc., can solve the problems of inability to transfer electrons and holes in time, low photoconversion efficiency, etc. Good, high catalytic activity, efficient degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

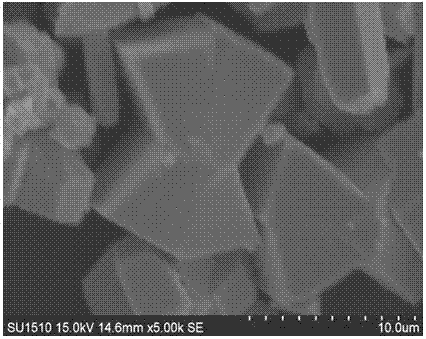

[0022] Embodiment 1: the preparation of bowtie-shaped bismuth oxyfluoride photocatalyst

[0023] Add 0.45g of bismuth nitrate pentahydrate to 15mL of water, and stir for 20 minutes; then add 0.25g of ammonium fluoride while stirring, and continue stirring for 10 minutes to form a mixed solution; Thermal reaction, the hydrothermal reaction condition is 150°C for 12 hours; after the reaction, cool for 2 hours, and centrifuge at 3000r / min for 3 minutes to obtain a precipitate. The precipitate was washed twice by centrifugation with pure water (3000 rpm, 2 minutes each time), and then washed twice with absolute ethanol (3000 rpm, 2 minutes each time). minutes), dried at 60°C for 2 hours to obtain the bow-tie bismuth oxyfluoride photocatalyst Bi 7 f 11 o 5 .

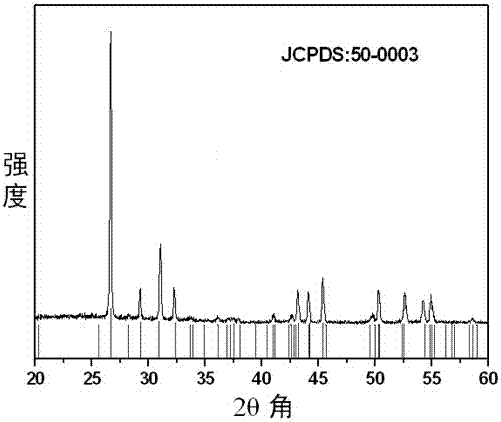

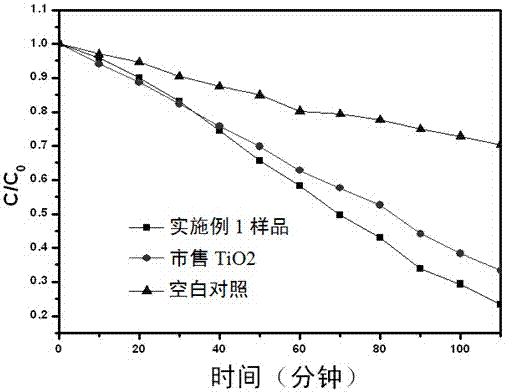

[0024] figure 2 The X-ray diffraction (XRD) pattern of the bow-tie-shaped bismuth oxyfluoride photocatalyst prepared in Example 1, and the XRD standard card (JCPDS: 50-0003), illustrate that the bow-tie-shaped bismuth o...

Embodiment 2

[0025] Embodiment 2: preparation of bowtie-shaped bismuth oxyfluoride photocatalyst

[0026] Add 0.4g of bismuth nitrate pentahydrate to 15mL of water, and stir for 15 minutes; then add 0.2g of ammonium fluoride while stirring, and continue stirring for 5 minutes to form a mixed solution; Thermal reaction, the hydrothermal reaction condition is 140°C for 14 hours; after the reaction, cool for 2 hours, and centrifuge at 2500r / min for 4 minutes to obtain a precipitate. The precipitate was washed twice by centrifugation with pure water (3000 rpm, 2 minutes each time), and then washed twice with absolute ethanol (3000 rpm, 2 minutes each time). minutes), dried at 50°C for 3 hours to obtain the bow-tie bismuth oxyfluoride photocatalyst Bi 7 f 11 o 5 . The SEM and XRD patterns of the bowtie-shaped bismuth oxyfluoride photocatalyst prepared in Example 2 are consistent with those in Example 1.

Embodiment 3

[0027] Embodiment 3: the preparation of bowtie-shaped bismuth oxyfluoride photocatalyst

[0028] Add 0.5g of bismuth nitrate pentahydrate to 15mL of water, and stir for 25 minutes; then add 0.3g of ammonium fluoride while stirring, and continue stirring for 15 minutes to form a mixed solution; Thermal reaction, the hydrothermal reaction condition is 160°C for 10 hours; after the reaction, cool for 2 hours, and centrifuge at 3500r / min for 2 minutes to obtain a precipitate. The precipitate was washed twice by centrifugation with pure water (3000 rpm, 2 minutes each time), and then washed twice with absolute ethanol (3000 rpm, 2 minutes each time). minutes), dried at 70°C for 1 hour to obtain the bow-tie bismuth oxyfluoride photocatalyst Bi 7 f 11 o 5 . The SEM image and XRD image of the bowtie-shaped bismuth oxyfluoride photocatalyst prepared in Example 3 are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com