Preparation method for nitrogen-boron-doped carbon-based catalyst

A carbon-based catalyst, nitrogen-boron technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of low equipment requirements, good industrial application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

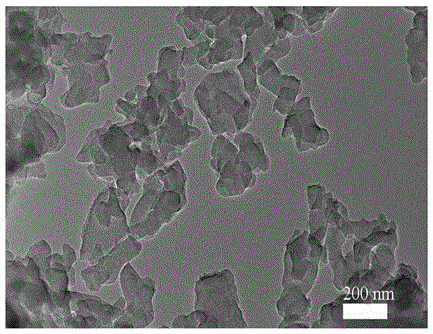

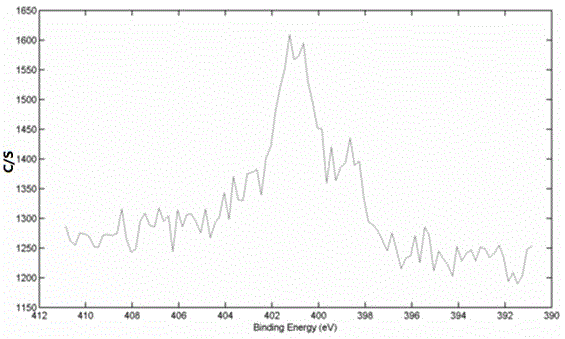

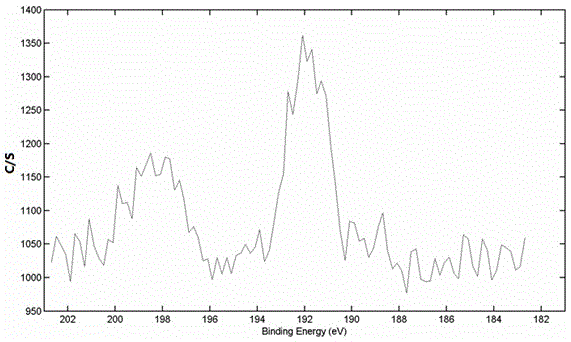

Image

Examples

Embodiment 1

[0032] (1) Weigh 20g of conductive carbon black (EC300J) and soak it in dilute sulfuric acid with a concentration of 0.5 mol / L for 24 hours, then filter it with suction, wash it with distilled water for 3 times, and dry it in vacuum at 60°C for 1 hour to obtain the pretreatment carbon materials;

[0033](2) Weigh 10g of conductive carbon black (EC300J) pretreated in step (1), and polyaniline (nitrogen donor), sodium fluoroborate and fluoboric acid (boron donor) and thiourea (activator) by mass The percentages are 60%, 18%, 10%, and 12%, respectively, mixed in a mortar and mechanically ball-milled for 60 minutes, wherein the mass ratio of the boron-donating agent sodium fluoroborate and fluoroboric acid is 1:1;

[0034] (3) Move the mixture of mechanical ball milling in step (2) into a ceramic boat, and then put it into a quartz tube resistance furnace. Under the protection of an inert gas (nitrogen), first raise the temperature to 300°C at a rate of 15°C / min. Keep it for 10 m...

Embodiment 2

[0039] (1) Weigh 20g of conductive carbon black (Vulcan XC-7) and soak it in dilute sulfuric acid with a concentration of 0.25 mol / L for 6 hours, then filter it with suction, wash it with twice distilled water 4 times, and dry it in vacuum at 40°C for 2 hour, obtain the pretreated carbon material;

[0040] (2) Weigh 10g of conductive carbon black (Vulcan XC-7) pretreated in step (1), mix with o-phenanthrene (nitrogen donor), sodium fluoroborate and fluoroboric acid (boron donor) and hydrogen fluoride Sodium bicarbonate (activator) was 50%, 30%, 6%, and 14% by mass percentage, mixed in a mortar and mechanically ball-milled for 30 minutes, and the mass ratio of boron-donating agent sodium fluoroborate to fluoroboric acid was 1:1 ;

[0041] (3) Move the mixture of mechanical ball milling in step (2) into a ceramic boat, and then put it into a quartz tube resistance furnace. Under the protection of an inert gas (nitrogen), first raise the temperature to 300°C at a rate of 10°C / mi...

Embodiment 3

[0045] (1) Weigh 20g of conductive carbon black (BP2000) and soak it in dilute sulfuric acid with a concentration of 1.5 mol / L for 48 hours, then filter it with suction, wash it with twice distilled water for 5 times, and dry it in vacuum at 100°C for 4 hours to obtain Pretreated carbon materials;

[0046] (2) Weigh 10g of conductive carbon black (BP2000) pretreated in step (1), and melamine (nitrogen donor), sodium fluoroborate and fluoroboric acid (boron donor) and urea (activator) respectively by mass percentage 74%, 10%, 6%, 10%, mixed in a mortar and mechanically milled for 120 minutes, wherein the mass ratio of boron-donating agent sodium fluoroborate to fluoroboric acid is 1:1;

[0047] (3) Move the mixture of mechanical ball milling in step (2) into a ceramic boat, and then put it into a quartz tube resistance furnace. Under the protection of an inert gas (argon), first raise the temperature to 300°C at a rate of 20°C / min. , kept for 60 minutes, and then raised to 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com