Preparation method for fluorinated carbon material

A technology of carbon materials and carbon fluoride, applied in the electrolysis process, electrolysis components, etc., can solve problems such as danger, harsh reaction conditions, and difficult storage and transportation of fluorine gas, so as to reduce preparation costs, improve product quality, and eliminate diaphragm pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

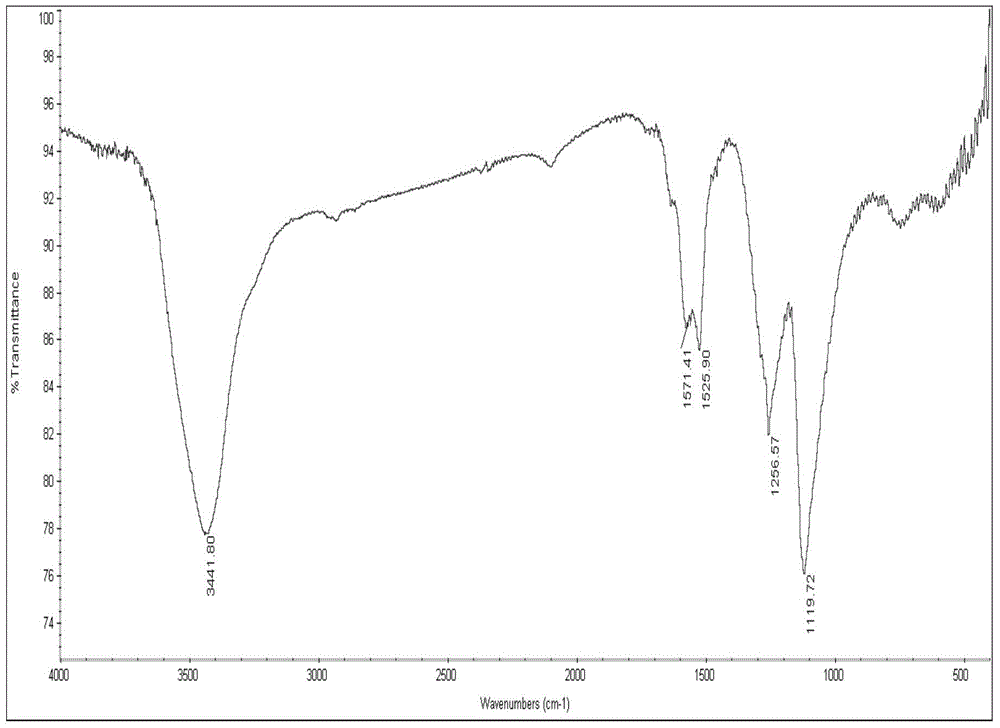

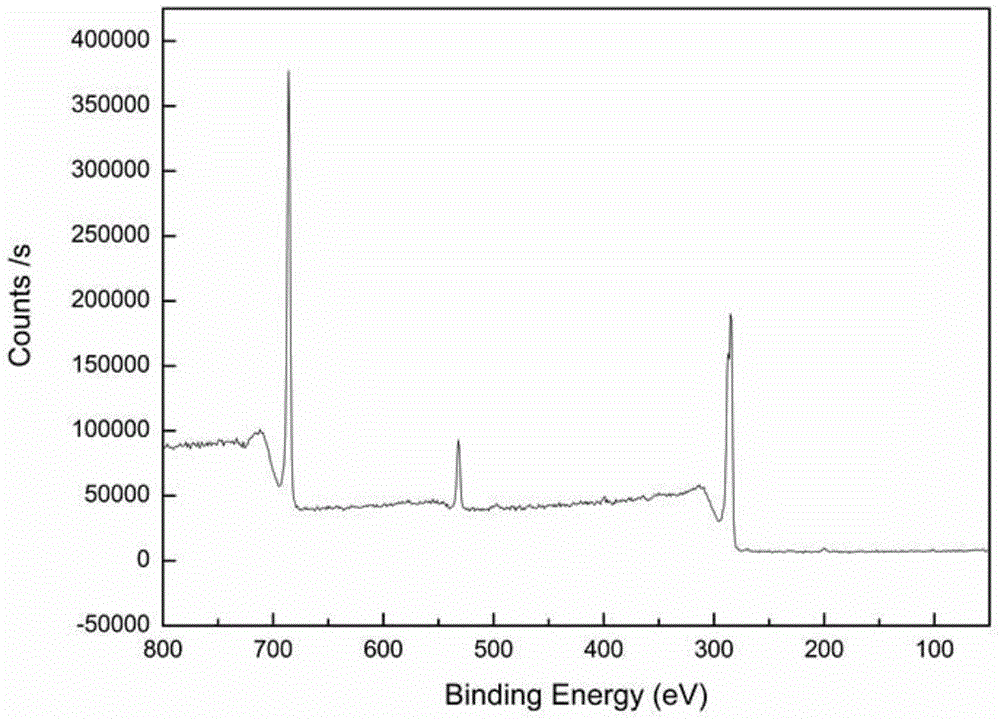

[0024] Specific embodiment 1: The preparation method of the fluorinated carbon material of this embodiment is carried out according to the following steps;

[0025] 1. In a single-chamber electrolyzer, nickel, iron or nickel-titanium alloy is used as cathode, nickel or nickel alloy is used as anode, metal fluoride is used as supporting electrolyte, carbon material is used as raw material, and a hydrogen fluoride aqueous solution with a mass concentration of ≥90% As an electrolyte, put the metal fluoride and carbon material into the electrolyte, and perform electrolytic fluorination under the conditions of electrolyte temperature of -10~10℃ and voltage of 4~10V, electrolysis for 1~36h, fluorination reaction End;

[0026] 2. After the electrolytic fluorination reaction is over, cool the electrolytic cell to -20°C, and use a PTFE tube to introduce the electrolyte, metal fluoride and fluorinated carbon materials in the electrolytic cell into perfluoropolyethylene-propylene. In the pla...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that the carbon material described in step 1 is graphite powder, graphene, single-walled carbon nanotubes or multi-walled carbon nanotubes. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the single-chamber electrolytic cell described in step one is equipped with a stirring device, and the volume is 30-100 mL. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com