Low-bubble weak-acid chloride zinc-nickel alloy electroplate liquid

A zinc-nickel alloy and electroplating solution technology, applied in the field of electroplating zinc-nickel alloys, can solve the problems of low brightness, poor corrosion resistance, and the plating solution cannot be operated by air stirring, and achieves a wide working temperature range, cost reduction, and network connection. Strong synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

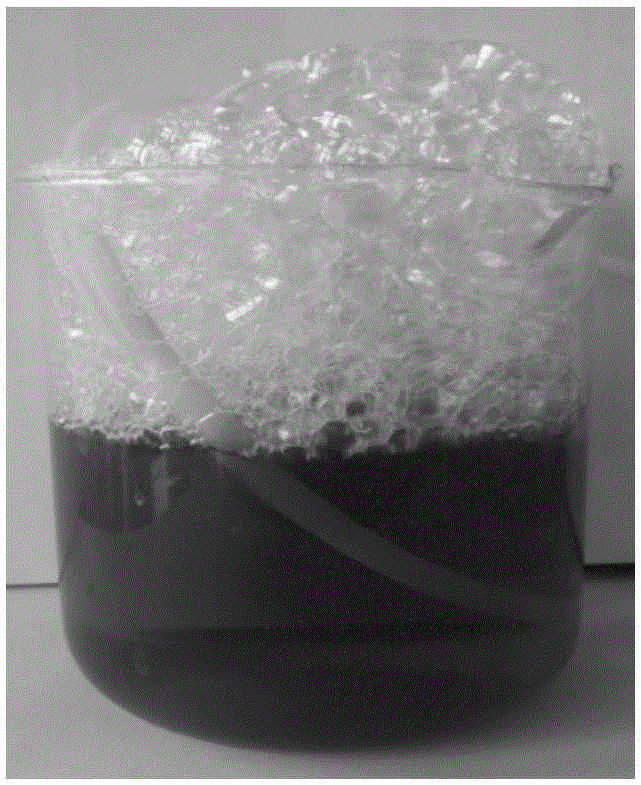

[0020] Specific embodiment one: the present embodiment is a kind of low-foam type weakly acidic chloride zinc-nickel alloy electroplating solution, it is characterized in that the component of this plating solution comprises zinc chloride, nickel chloride, potassium chloride, ammonium chloride, main Brighteners, carrier brighteners, displacement agents and complexing agents;

[0021] Wherein, the concentration of zinc chloride is 80~100g / L, the concentration of nickel chloride is 120~140g / L, the concentration of potassium chloride is 100~140g / L, the concentration of ammonium chloride is 50~80g / L, The concentration of the main brightener is 5-20mL / L, the concentration of the carrier brightener is 10-30mL / L, the concentration of the displacement agent is 10-20mL / L, and the concentration of the complexing agent is 20-50mL / L.

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the composition of the main brightener includes o-chlorocinnamic acid, formaldehyde and absolute ethanol; wherein, the concentration of o-chlorocinnamic acid is 10-30g / L , the formaldehyde concentration is 15-40g / L, and the balance is absolute ethanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the composition of the carrier brightener includes polyethylene glycol-400, polyethylene glycol-1000, polyethylene glycol-4000, polyethylene glycol -6000 and distilled water, wherein the concentration of polyethylene glycol-400 is 10-40g / L, the concentration of polyethylene glycol-1000 is 10-40g / L, the concentration of polyethylene glycol-4000 is 10-40g / L, and the concentration of polyethylene glycol-4000 is 10-40g / L. The concentration of ethylene glycol-6000 is 10-40g / L, and the balance is distilled water. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com