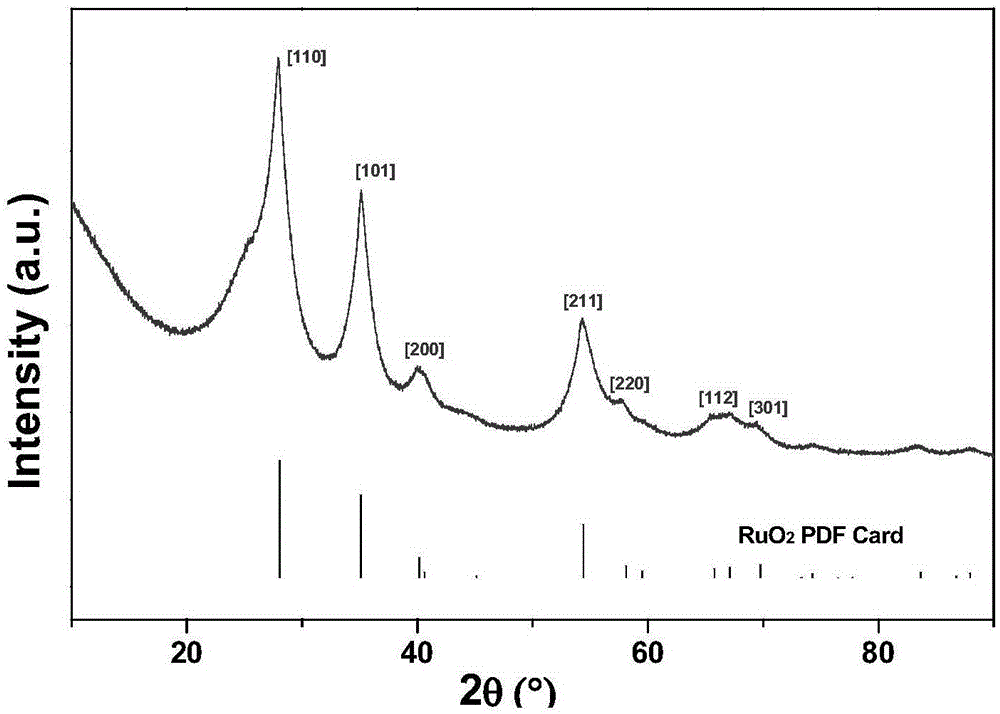

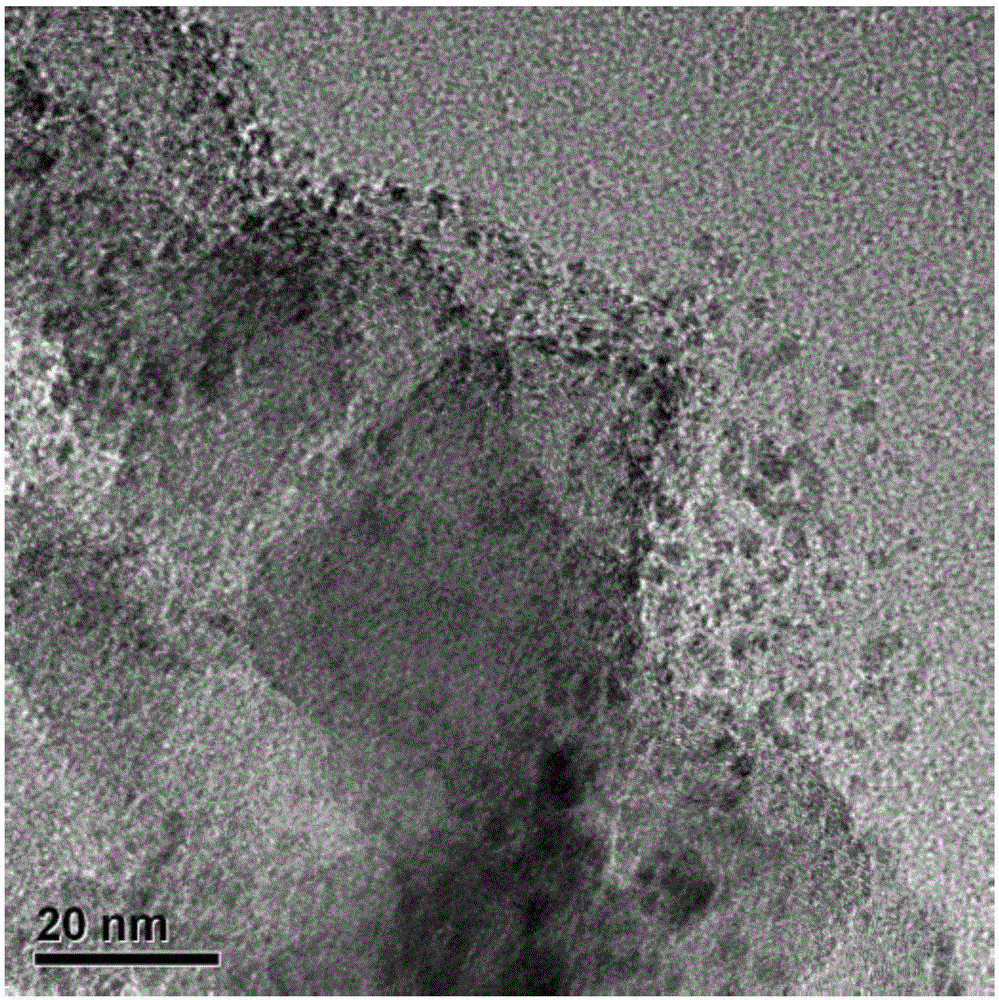

Ruthenium dioxide nanometer cluster/carbon composite material and preparation method thereof

A technology of carbon composite materials and nano-clusters, which is applied in nanotechnology, nanotechnology, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of application field limitations of large specific surface area, and achieve excellent electronic conductivity and proton transport capabilities , easy large-scale production, great application potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (a) Accurately weigh 10.35 mg of ruthenium chloride hydrate, add it to 50 ml of distilled water, stir and disperse, and fully dissolve the ruthenium chloride; simultaneously accurately weigh 189.15 mg of sodium borohydride and add it to 50 ml of distilled water, stir Disperse to fully dissolve sodium borohydride;

[0040] (b) Add the newly prepared aqueous solution of sodium borohydride dropwise to the ruthenium chloride solution, and simultaneously measure the pH change of the ruthenium precursor solution. When the pH rises to 4, stop the dropwise addition and continue stirring for a period of time to obtain a solution that can be stably dispersed in Ruthenium nanoclusters in water;

[0041](c) ultrasonically disperse 2.07 mg of carbon in water, then add the carbon dispersion to the prepared dispersion of ruthenium nanoclusters, stir and adsorb for 12 hours, filter, wash, and dry to obtain ruthenium nanoclusters / Carbon composite materials;

[0042] (d) Calcining the...

Embodiment 2

[0045] (a) Accurately weigh 2.07mg of ruthenium chloride hydrate, add it to 50ml of distilled water, stir to disperse, and fully dissolve the ruthenium chloride; simultaneously accurately weigh 134.85mg of potassium borohydride and add it to 50ml of distilled water, stir Disperse to fully dissolve potassium borohydride;

[0046] (b) Add the newly prepared aqueous solution of potassium borohydride dropwise to the ruthenium chloride solution, and simultaneously measure the pH change of the ruthenium precursor solution. When the pH rises to 4.2, stop the dropwise addition and continue stirring for a period of time to obtain a solution that can be stably dispersed in Ruthenium nanoclusters in water;

[0047] (c) ultrasonically disperse 0.6831 mg of carbon in water, then add the carbon dispersion to the prepared dispersion of ruthenium nanoclusters, stir and adsorb for 2 h, filter, wash, and dry to obtain ruthenium nanoclusters / Carbon composite materials;

[0048] (d) Calcining ...

Embodiment 3

[0051] (a) Accurately weigh 5.175mg of ruthenium chloride hydrate, add it to 50ml of distilled water, stir and disperse, and fully dissolve the ruthenium chloride; simultaneously accurately weigh 294.1mg of trisodium citrate and add it to 50ml of distilled water, Stir and disperse to fully dissolve trisodium citrate;

[0052] (b) Add the newly prepared trisodium citrate aqueous solution dropwise to the ruthenium chloride solution, and simultaneously measure the pH change of the ruthenium precursor solution. When the pH rises to 4.4, stop the dropwise addition and continue stirring for a period of time to obtain a stable dispersion. Ruthenium nanoclusters in water;

[0053] (c) ultrasonically disperse 5.175 mg of carbon in water, then add the carbon dispersion to the prepared dispersion of ruthenium nanoclusters, stir and adsorb for 4 h, filter, wash, and dry to obtain ruthenium nanoclusters / Carbon composite materials;

[0054] (d) Calcining the ruthenium nanocluster / carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com