LGA welding process method in printed circuit board processing

A soldering process and printed board technology, applied in printed circuit manufacturing, printed circuit, printed circuit, etc., to achieve stable output power, small ripples, and reduce the effects of tin-less loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

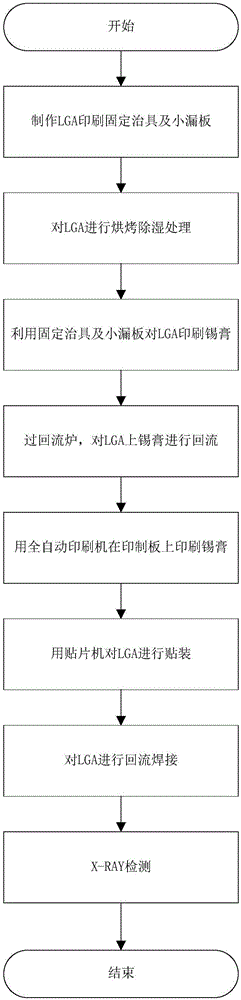

[0041] Process flow of the present invention such as figure 1 Shown:

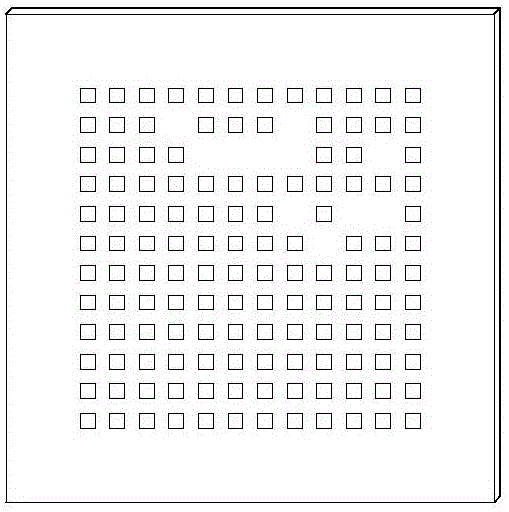

[0042] (1) Design and production of pre-treatment molds: making fixed fixtures and small bushings: According to the shape and size of the LGA and the conditions of the bottom terminals, the fixed fixtures and small bushings are prefabricated.

[0043] This step belongs to the pretreatment process before LGA welding. The fixed jig and small bushing are special jigs and steel sheet molds for pre-treatment of printing solder paste. The function of using the fixed jig and small bushing is It can improve the subsequent LGA welding effect.

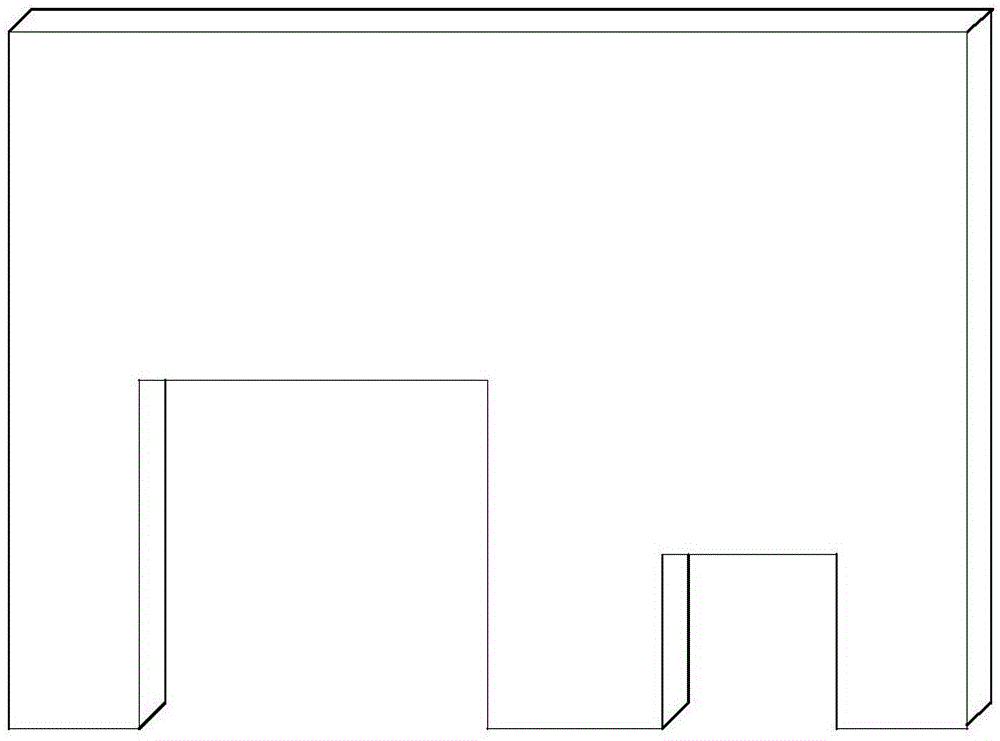

[0044] figure 2 is the graphic of the fixed fixture. The main body of the fixing jig is a flat steel plate with a thickness equal to that of the LGA to be fixed, and one or more notches consistent with the shape of the LGA to be fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com