Rod-like magnesium hydroxide particle and rod-like magnesium oxide particle each having high specific surface area, and methods respectively for producing said particles

A technology of magnesium oxide particles and magnesium hydroxide, applied in magnesium hydroxide, magnesium oxide and other directions, can solve the problems of low reactivity, low specific surface area, mixed and other problems, and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

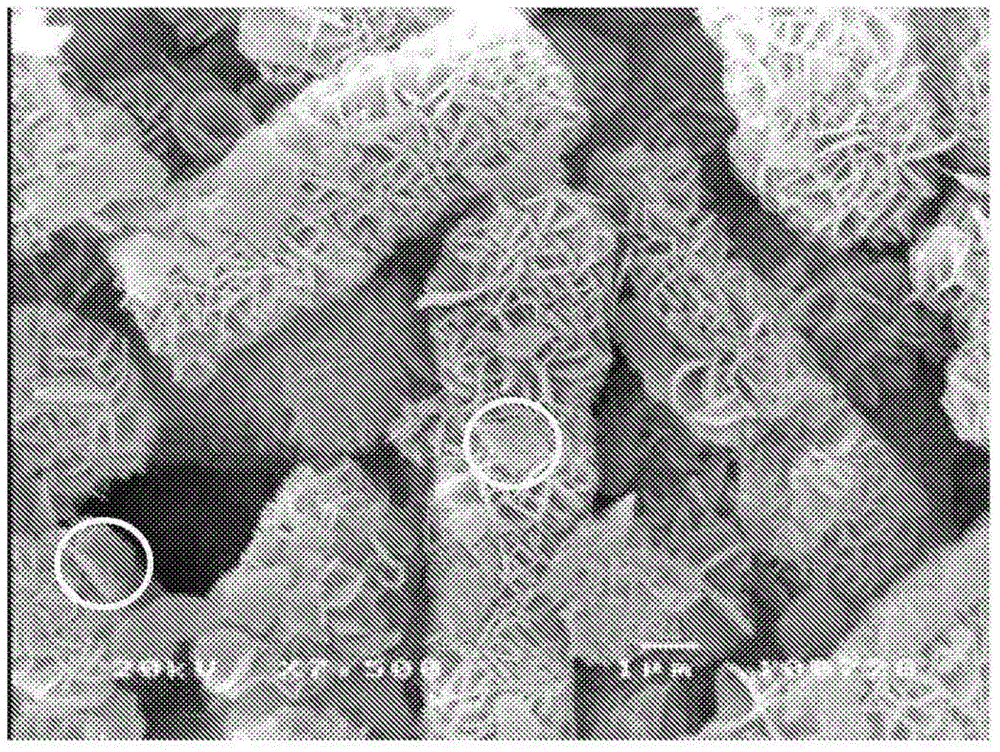

Image

Examples

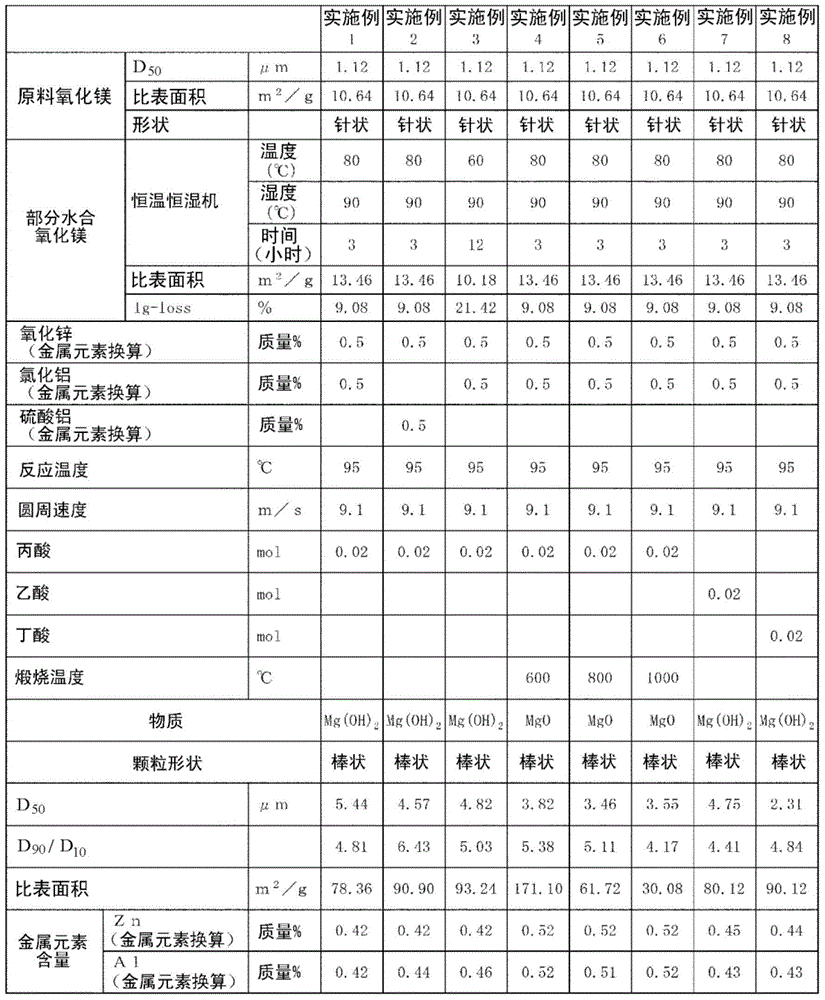

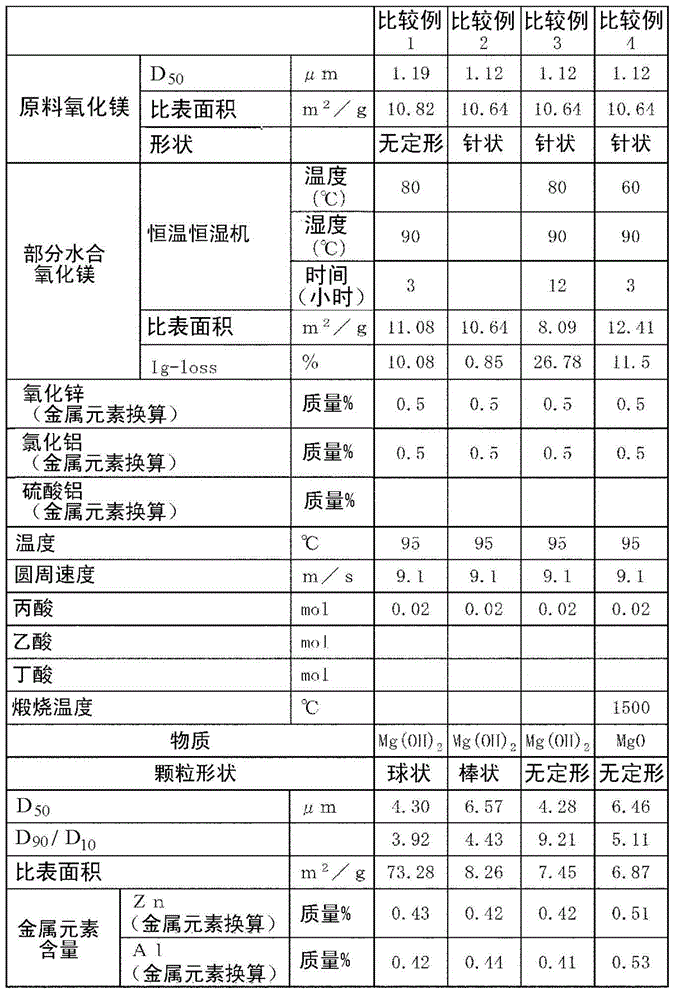

Embodiment 1

[0097] 50% particle size (D 50 ) is 1.12μm, and the specific surface area is 10.64m 2 / g of magnesium oxide is placed in a constant temperature and humidity machine with a temperature of 80°C and a humidity of 90% for 3 hours to partially hydrate the surface and obtain a specific surface area of 13.46m 2 Partially hydrated acicular magnesia / g, Ig-loss is 9.08%, wherein, described magnesia is the acicular magnesium carbonate that will make magnesium sulfate solution and sodium carbonate react and make under calcination temperature 1200 ℃. made by calcination.

[0098] 0.5% by mass of aluminum chloride in terms of metal elements was added to an ion-exchange aqueous solution containing 0.5% by mass of zinc oxide in terms of metal elements and 1 liter of ion-exchanged water relative to the partially hydrated acicular magnesium oxide used in the reaction - Hexahydrate and 0.02 mol of propionic acid with respect to 100 g of partially hydrated acicular magnesia to prepare a react...

Embodiment 2

[0101] Except having used aluminum sulfate instead of aluminum chloride, it carried out similarly to Example 1.

Embodiment 3

[0103] Place needle-shaped magnesium oxide in a constant temperature and humidity machine with a temperature of 60°C and a humidity of 90% for 12 hours to partially hydrate the surface and set the specific surface area to 10.18m 2 / g and Ig-loss were set to 21.42%, and it carried out similarly to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com