Nano thin sheet assembled nickel-iron hydroxide multistage microspheres and preparation method thereof

A technology of hydroxide and nano-flakes, applied in nickel compounds, chemical instruments and methods, nanotechnology, etc., can solve the problem of high charge density, and achieve the effects of simple operation, cheap raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ①In a 100ml flask, add 0.8mmol of ferric nitrate, 2.4mmol of nickel nitrate, and 6.4mmol of urea into 40ml of water, stir vigorously for 10min, then add 15mg of trisodium citrate and 40ml of n-butanol. Continue strong magnetic stirring to prepare a reaction solution of layered double hydroxide NiFe-LDHs multi-level microspheres assembled by single-layer and double-layer nanosheets.

[0036] ② Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 100ml polytetrafluoroethylene liner. After reacting at 120°C for 12 hours, the reactor was naturally cooled to 20°C, washed several times with absolute ethanol, and vacuum After drying the sample, the layered double metal hydroxide NiFe-LDHs multi-level microspheres assembled by single-layer and double-layer nanosheets can be obtained.

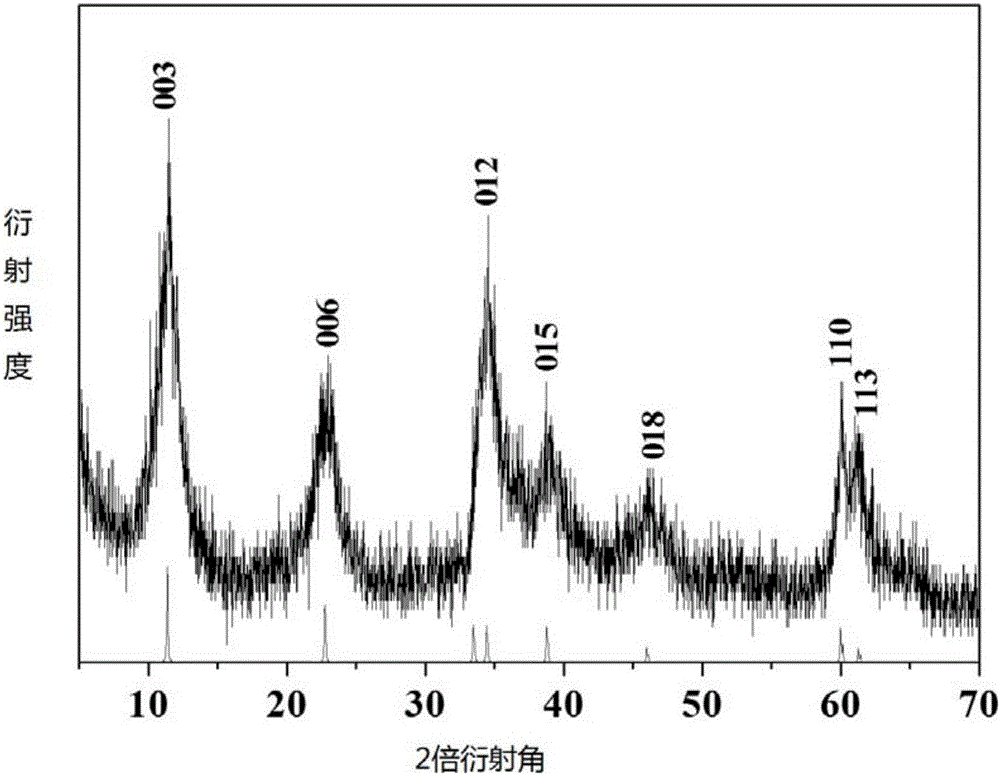

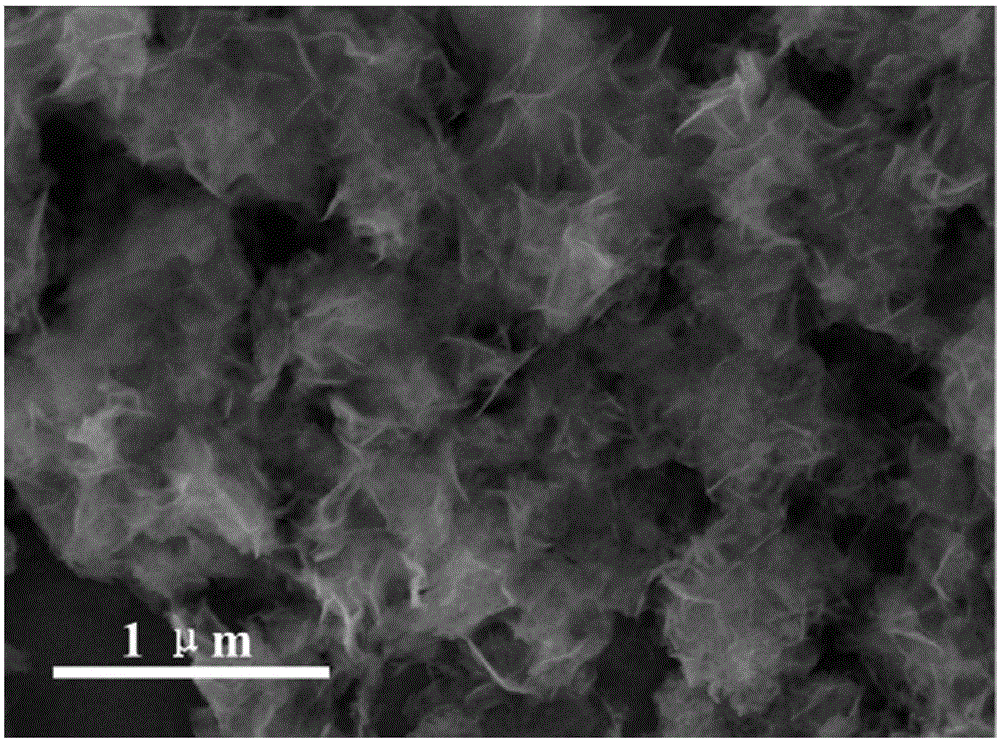

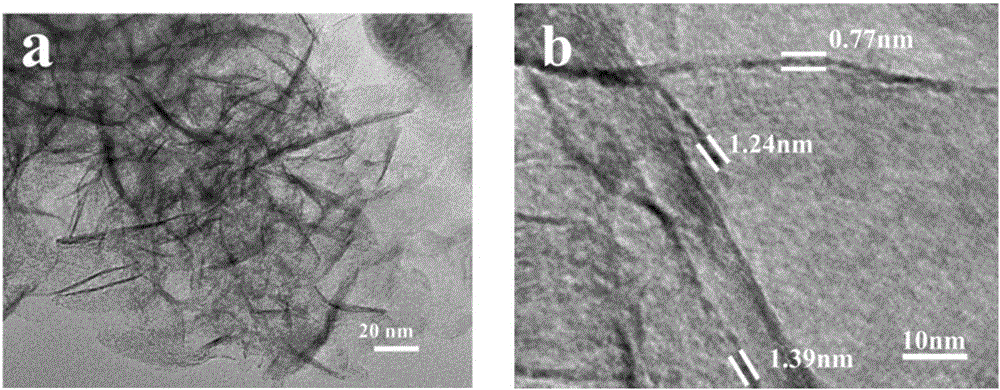

[0037] The X-ray diffraction pattern of the obtained layered double metal hydroxide NiFe-LDHs multi-level microspheres assembled by single-layer nanoshe...

Embodiment 2

[0042] ①In a 100ml flask, add 0.8mmol of ferric nitrate, 2.4mmol of nickel nitrate, and 6.4mmol of sodium carbonate into 40ml of water, stir vigorously for 10min and then add 15mg of trisodium citrate and 40ml of n-butanol. At the same time, the strong magnetic stirring is continued to prepare the reaction solution of layered double hydroxide NiFe-LDHs nanosheets.

[0043] ② Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 100ml polytetrafluoroethylene liner. After reacting at 120°C for 12 hours, the reactor was naturally cooled to 20°C, washed several times with absolute ethanol, and vacuum Dry the sample to obtain layered double hydroxide NiFe-LDHs nanosheets.

[0044] Figure 6 is the X-ray diffraction pattern of the obtained layered double hydroxide NiFe-LDHs nanosheet, Figure 7 is the scanning electron micrograph of the obtained layered double hydroxide NiFe-LDHs nanosheets. It can be seen from the figure that the layered...

Embodiment 3

[0046] ①In a 100ml flask, add 0.8mmol of ferric nitrate, 2.4mmol of nickel nitrate, and 6.4mmol of sodium acetate into 40ml of water, stir vigorously for 10min, then add 15mg of trisodium citrate and 40ml of n-butanol. At the same time, the strong magnetic stirring is continued to prepare the reaction solution of layered double hydroxide NiFe-LDHs nanosheets.

[0047] ② Transfer the reaction solution prepared according to step ① into a high-pressure reactor with a 100ml polytetrafluoroethylene liner. After reacting at 120°C for 12 hours, the reactor was naturally cooled to 20°C, washed several times with absolute ethanol, and vacuum Dry the sample to obtain layered double hydroxide NiFe-LDHs nanosheets.

[0048] Figure 8 is the X-ray diffraction pattern of the obtained layered double hydroxide NiFe-LDHs nanosheet, Figure 9 Its scanning electron microscope photograph. It can be seen from the figure that the phase of the product of this example is a typical bimetallic compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com