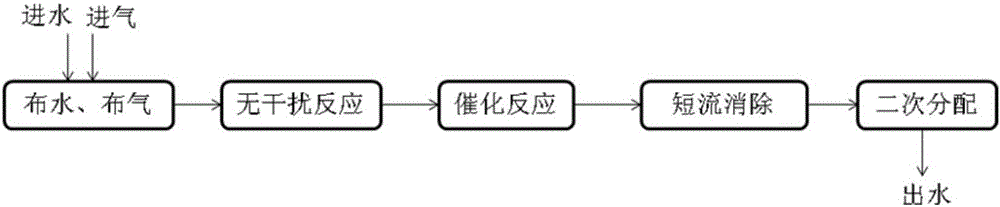

Method for improving ozone reaction efficiency

A reaction efficiency and ozone technology, applied in the field of improving ozone reaction efficiency, can solve the problems of low oxidation treatment efficiency and low ozone utilization efficiency, and achieve the effects of improving ozone utilization efficiency, improving oxidation efficiency, and increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

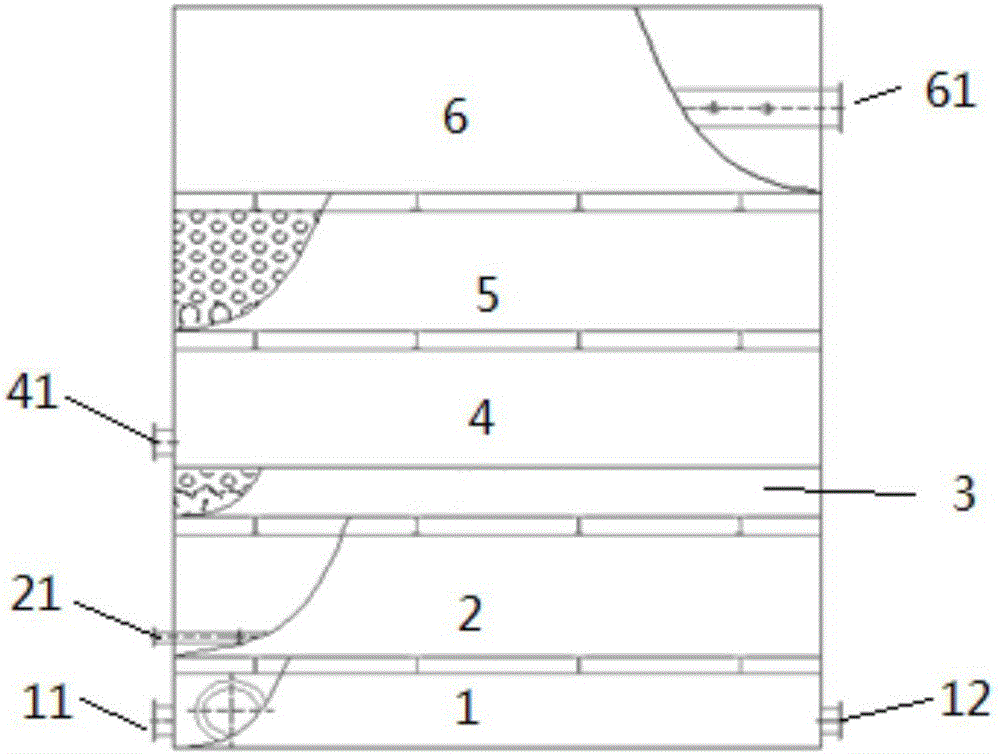

[0040] The invention aims at the technical problems existing in the existing ozone reaction device: 1) the ozone utilization efficiency is not high; 2) the oxidation treatment efficiency is low; 3) there are ozone residues in the effluent water and other difficulties. The present invention has developed a kind of device that improves ozone reaction efficiency for described method, as figure 2 As shown, the device is provided with water inlet and backwash layer 1, non-interference reaction layer 2, catalyst layer 3, short flow elimination layer 4, secondary distribution layer 5, and top water outlet layer 6 from bottom to top. The same side of the washing layer 1 and the non-interference reaction layer 2 are respectively provided with a water inlet 11 and an air inlet 21, and the other side of the water inlet and backwashing layer 1 is provided with a flushing port 12, which is used for backwashing the device to prevent The device runs for a long time, and the sediment in the ...

Embodiment 2

[0053] A method for improving ozone reaction efficiency, its method steps are the same as embodiment 1, wherein, in step A, the gas-liquid ratio is controlled to be 0.5:1, the wastewater pH is adjusted to 6.0, COD is at 70mg / L, and the ozone mass concentration in the mixed gas is 5%, the mass concentration of oxygen is 95%, the aeration disc can cut the ozone gas into tiny bubbles, and the average diameter of the bubbles is 0.5μm.

[0054] In step B, the two phases of water and gas are in the non-interference reaction layer 2 for non-interference reaction, and the residence time of the gas-water mixture in this stage, that is, the reaction time is 5 minutes.

[0055]In step C, the catalytic material used is a supported composite catalytic material, the material is a catalyst filler NDC-003, NDC-005, NDC-001, NDC-002, and the carrier is a porous material, such as silica gel, activated carbon, ceramics or resin, etc., The load is one or more mixtures of heavy metals such as copp...

Embodiment 3

[0057] A method for improving ozone reaction efficiency, the method steps are the same as in Example 1, wherein the gas-liquid ratio in step A is controlled to be 1:1, the pH of the wastewater is adjusted to 7.5, the COD is at 90 mg / L, and the mass concentration of ozone in the mixed gas is 10%, the oxygen mass concentration is 90%, the aeration disc can cut the ozone gas into tiny bubbles, and the average diameter of the bubbles is 10μm.

[0058] In step B, the two phases of water and gas are in the non-interference reaction layer 2 for non-interference reaction, and the residence time of the gas-water mixture in this stage, that is, the reaction time is 10 minutes.

[0059] In step C, the catalytic material used is a supported composite catalytic material, the material is a catalyst filler NDC-003, NDC-005, NDC-001, NDC-002, and the carrier is a porous material, such as silica gel, activated carbon, ceramics or resin, etc., The load is one or more mixtures of heavy metals su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com