A kind of blue carbon wastewater treatment process

A technology of blue carbon wastewater and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect and unsatisfactory comprehensive effect, etc. Short production process, easy blockage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

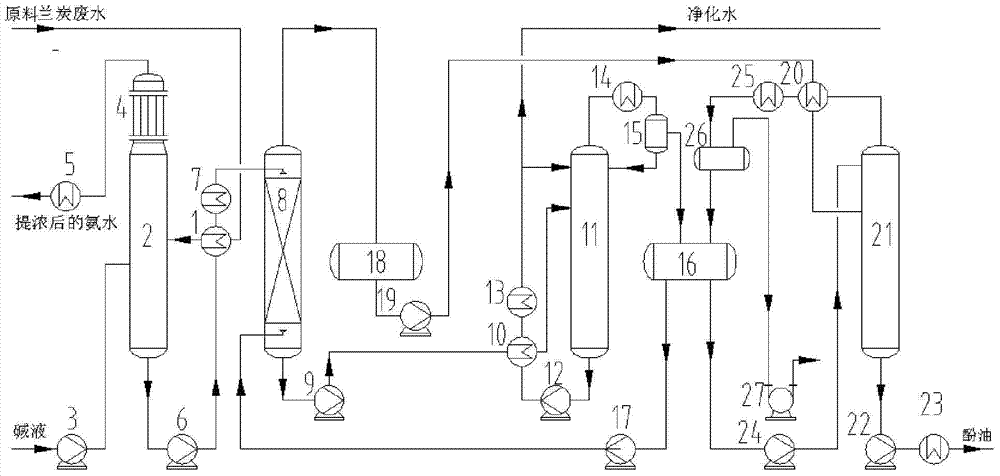

[0047] Apply the above-mentioned process device and process flow, the raw material semi-coke wastewater flow rate is 12 tons / hour, according to the above-mentioned process flow figure 1 process shown. The main control parameters of each process are as follows:

[0048] 1) Deamination

[0049] The inner diameter of the deamination tower is D = 1000mm, the number of trays is 30, and the membrane spraying is used without mixed return trays, and the spacing between the plates is 450mm;

[0050] The temperature at the top of the deamination tower is 86°C, the pressure at the top of the tower is 0.12MPa, the temperature at the bottom of the tower is 120°C, and the pressure at the bottom of the tower is 0.14MPa; the content of ammonia nitrogen in the deamination wastewater is less than 150mg·L -1

[0051] 2) Extraction

[0052] The extractant is composed of 65% (v / v) methyl isobutyl ketone (MIBK) and 35% (v / v) butyl acetate (BA), and the extraction tower adopts a DN1400 / 1000 vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com