Ca-Nd-Ti microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and microwave technology, which is applied in the field of preparation of high-quality factor Ca-Nd-Ti microwave dielectric ceramic materials, can solve the problems of low dielectric constant of materials, frequency temperature coefficient hindering promotion, etc., and achieve high dielectric constant, Inexpensive and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

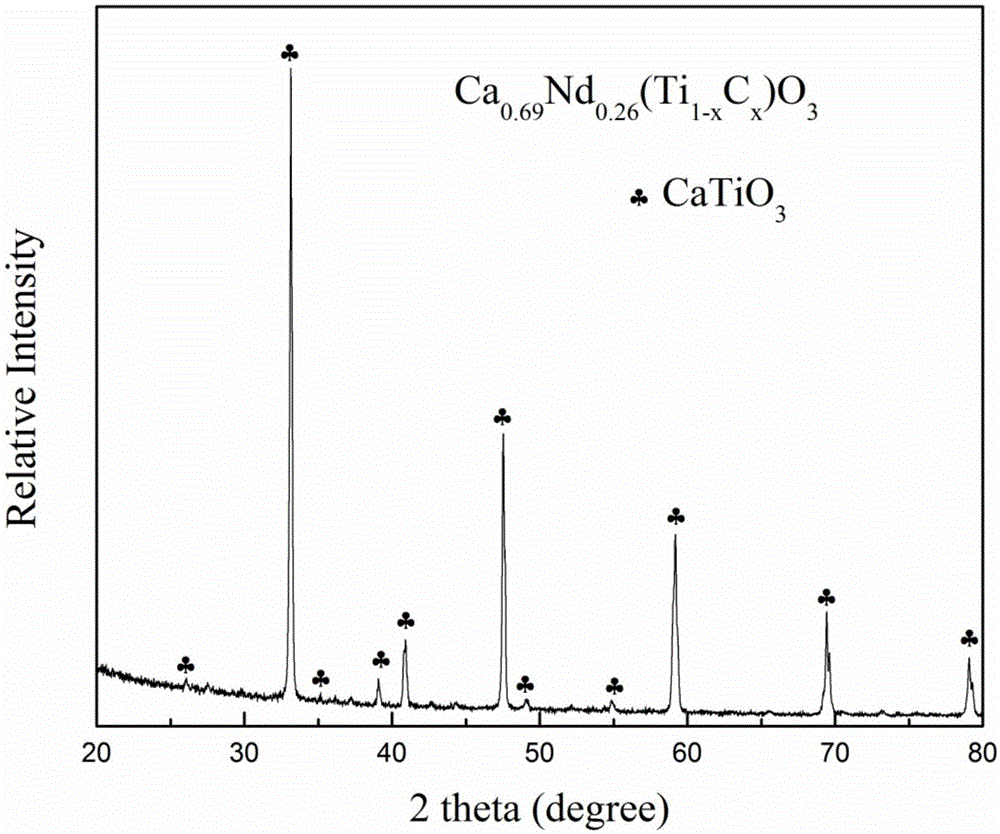

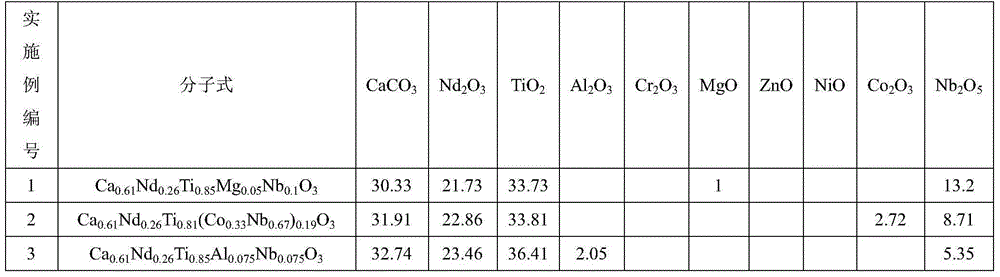

[0035] A microwave dielectric ceramic material substituted by B site, the general chemical formula is Ca 0.61 Nd 0.26 (Ti 1-x C x )O 3 , C=MN, where 0.15≤x≤0.2, the purpose of controlling the microwave performance of the system is achieved by replacing the B position, and the value of x is adjusted to control the microwave performance of the system; M represents Nb with a higher valence than tetravalent, and N represents a low valence For one or several other elements that are tetravalent and have an ionic radius similar to Ti, M and N can be substituted simultaneously or individually.

[0036] N is one or more of Zn, Co, Ni, Mg, Al, Cr. When MN is substituted at the same time, if N is Al, Cr, then the molar ratio N:M=1:1, if N is one or more of Zn, Co, Ni, Mg, then the total molar ratio N: M=1:2.

[0037] The crystal phase of the microwave dielectric ceramic material is a perovskite structure.

[0038] The Q×f value of the microwave dielectric ceramic material is betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com