Preparation method of cationic type fluorine-containing soap-free emulsion

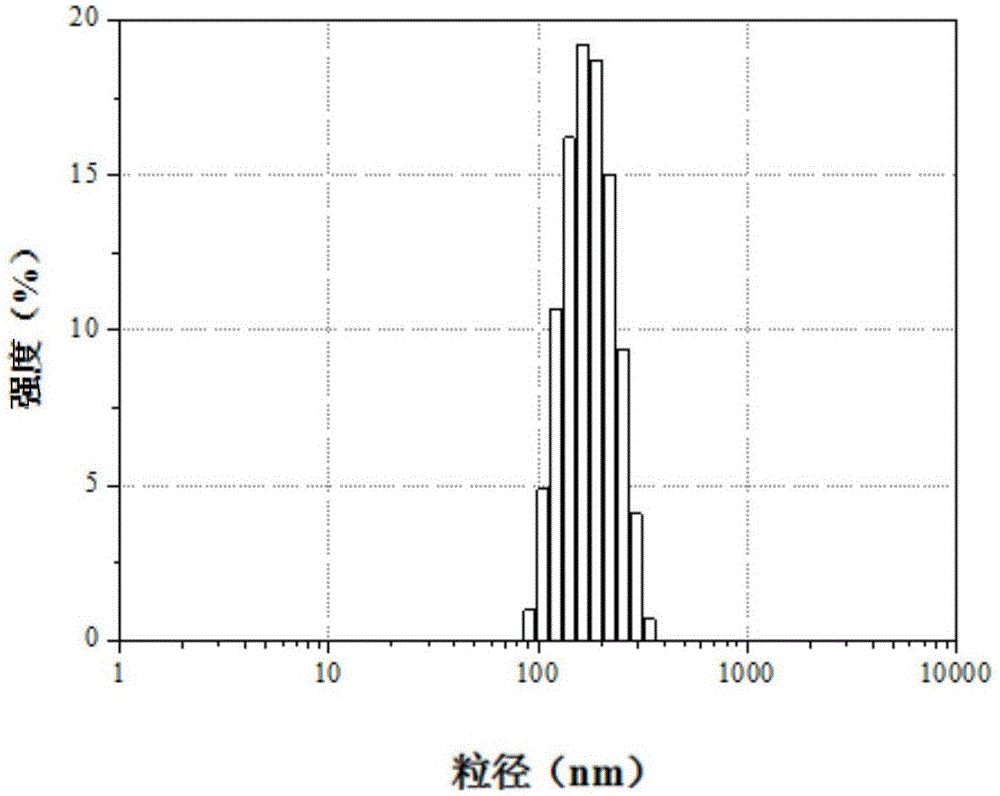

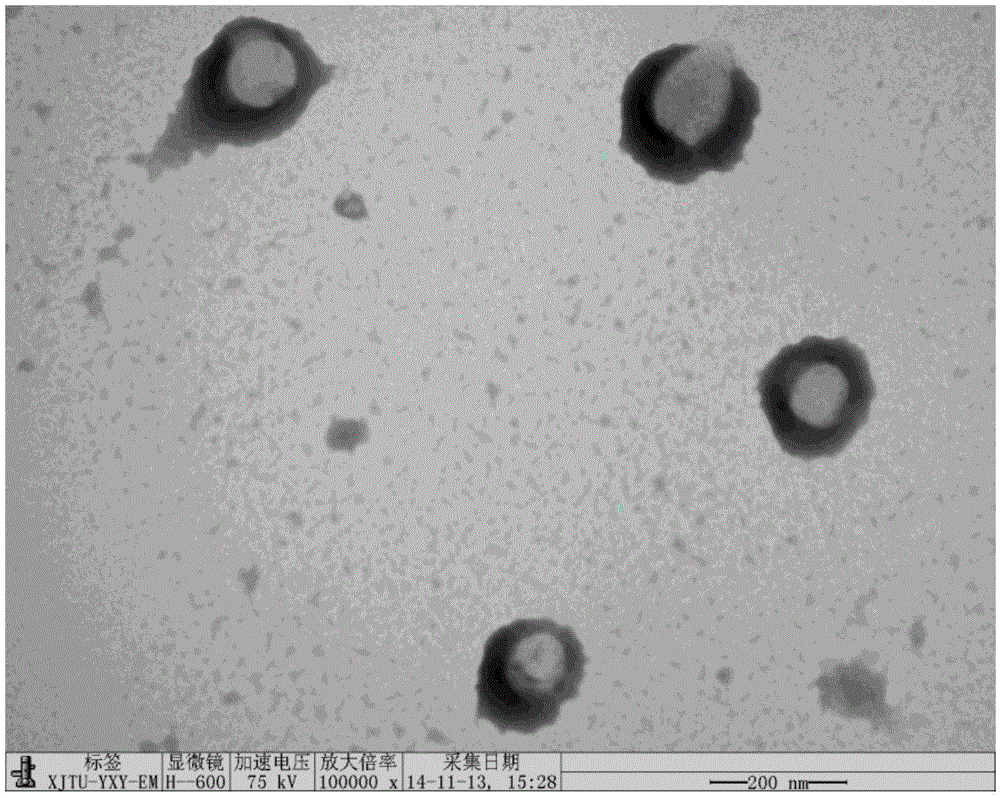

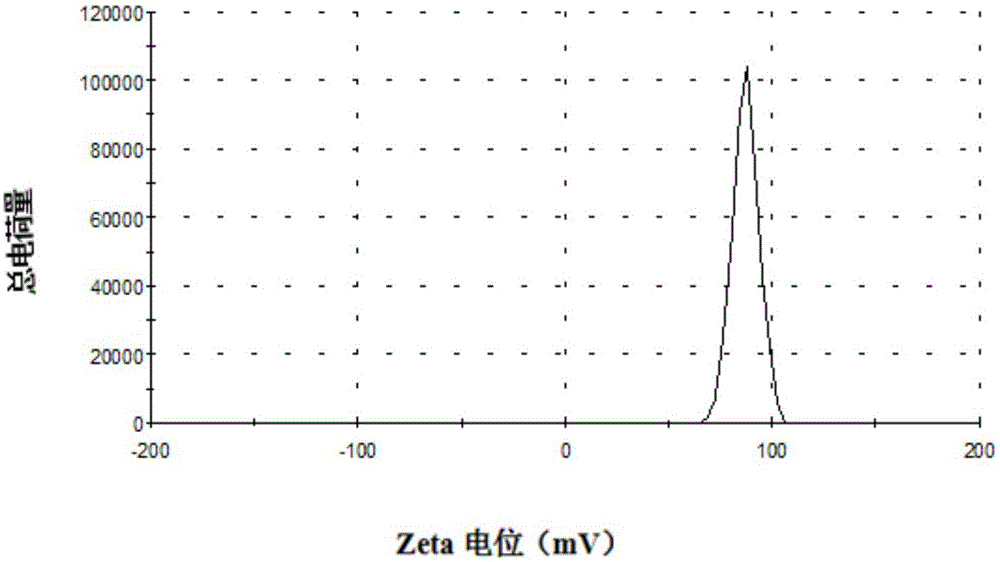

A soap-free emulsion and cationic technology, which is used in the field of soap-free emulsion and leather finishing preparation, can solve the problems of reduced polymer product performance, uncontrollable molecular weight, wide molecular weight distribution, etc., and achieves improved performance, good stability, Small particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of a cationic fluorine-containing soap-free emulsion of the present invention is specifically implemented according to the following steps:

[0051] Step 1. Weigh azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1 respectively according to the mass ratio of 1:39 to 90:143:3 - dodecyl-S'-(α,α"-dimethyl-α"-acetic acid) trithiocarbonate;

[0052] Step 2, using the azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl-S'- (α, α "-dimethyl-α "-acetic acid) trithiocarbonate is prepared to obtain polymethacrylate N, N dimethylaminoethyl ester (also known as: PDMAEMA-RAFT), specifically according to the following steps:

[0053] Step 2.1, at room temperature, the azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecane weighed in step 1 Base-S'-(α, α"-dimethyl-α"-acetic acid) trithiocarbonate is added together in a three-necked flask equipped with a magnet;

[0054...

Embodiment 1

[0083] Weigh azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl respectively according to the mass ratio of 1:39:143:3 -S'-(α,α"-dimethyl-α"-acetic acid) trithiocarbonate;

[0084] At room temperature, the weighed azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl-S'-( α, α″-dimethyl-α″-acetic acid) trithiocarbonate was added together in a three-necked flask equipped with a magnet; wherein, the three necks of the three-necked flask were connected from left to right with a thermometer, reflux condensing Pipe, air guide tube; first pass argon gas into the three-necked flask for 20 minutes, and then heat the three-necked flask to 70°C under the state of argon gas, so that the azobisisobutyronitrile and methacrylic acid in the three-necked flask N, N Dimethylaminoethyl ester, 1,4-dioxane, S-1-dodecyl-S′-(α,α″-dimethyl-α″-acetic acid) trithiocarbonate in argon Protect and react, the reaction time is 6h, to obta...

Embodiment 2

[0089] Weigh azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl respectively according to the mass ratio of 1:50:143:3 -S'-(α,α"-dimethyl-α"-acetic acid) trithiocarbonate;

[0090] At room temperature, the weighed azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl-S'-( α, α″-dimethyl-α″-acetic acid) trithiocarbonate was added together in a three-necked flask equipped with a magnet; wherein, the three necks of the three-necked flask were connected from left to right with a thermometer, reflux condensing Tube, air guide tube; first pass argon gas into the three-necked flask for 25 minutes, and at this time 1,4-dioxane is used as a solvent; then, under the state of re-passing argon gas, heat the three-necked flask to 75°C to make the three-necked flask Azobisisobutyronitrile, N,N dimethylaminoethyl methacrylate, 1,4-dioxane, S-1-dodecyl-S'-(α,α"-dimethyl- α″-acetic acid) trithiocarbonate was reacted under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com