Tackifying and filtrate reducing agent for low soil phase and high density drilling fluid, and preparation method thereof

A fluid loss additive, high-density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced drilling fluid viscosity and shear force, inability to meet drilling needs, and reduced ability to carry cuttings, etc. Achieve the effect of reducing fluid loss, improving wellbore stability, and increasing liquid viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

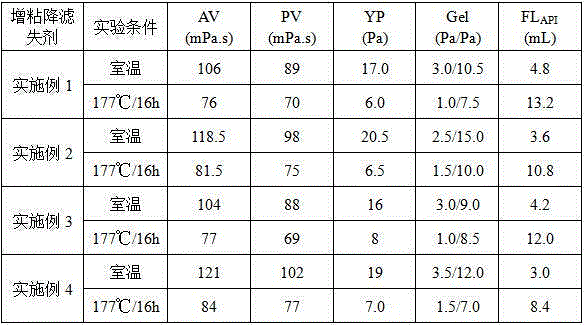

Examples

Embodiment 1

[0018] (1) Weigh 10.34g of acrylic acid, 3.45g of 2-acrylamido-2-methylpropanesulfonic acid, 31.02g of acrylamide, 3.45g of acrylonitrile and 1.72g of N-isopropylacrylamide in a three-necked flask;

[0019] (2) Add a certain amount of distilled water to dissolve the monomer, add 0.05g of silane coupling agent, stir evenly, adjust the pH to 6 with a measured sodium hydroxide aqueous solution, and then add distilled water to adjust the mass concentration of the system to 20%;

[0020] (3) At 30°C, after 30 minutes of driving oxygen with nitrogen, add 0.25 g of initiator ammonium persulfate and sodium bisulfite each, and react for 4 hours to obtain a viscous product;

[0021] (4) Dry and pulverize the viscous product to obtain the product fluid loss control agent.

Embodiment 2

[0023] (1) Weigh 5.0g of acrylic acid, 7.5g of 2-acrylamido-2-methylpropanesulfonic acid, 30.0g of acrylamide, 5.0g of acrylonitrile and 2.5g of N-isopropylacrylamide in a three-necked flask;

[0024] (2) Add a certain amount of distilled water to dissolve the monomer, add 0.125g of silane coupling agent, stir evenly, adjust the pH to 7 with a measured sodium hydroxide aqueous solution, and then add distilled water to adjust the system to a 30% aqueous solution;

[0025] (3) At 60°C, after driving oxygen with nitrogen for 30 minutes, add 0.1 g of initiator potassium persulfate and sodium bisulfite each, and react for 6 hours to obtain a viscous product;

[0026] (4) Dry and pulverize the viscous product to obtain the product fluid loss control agent.

Embodiment 3

[0028] (1) Weigh 14.29g of acrylic acid, 5.71g of 2-acrylamido-2-methylpropanesulfonic acid, 22.86g of acrylamide, 5.71g of acrylonitrile and 1.43g of N-isopropylacrylamide in a three-necked flask;

[0029] (2) Add a certain amount of distilled water to dissolve the monomer, add 0.15g of silane coupling agent, stir evenly, adjust the pH to 8 with a measured sodium hydroxide aqueous solution, and then add distilled water to adjust the system to a 40% aqueous solution;

[0030] (3) At 80°C, after 30 minutes of driving oxygen with nitrogen, add 0.15 g of initiator ammonium persulfate and sodium metabisulfite, and react for 8 hours to obtain a viscous product;

[0031] (4) Dry and pulverize the viscous product to obtain the product fluid loss control agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com