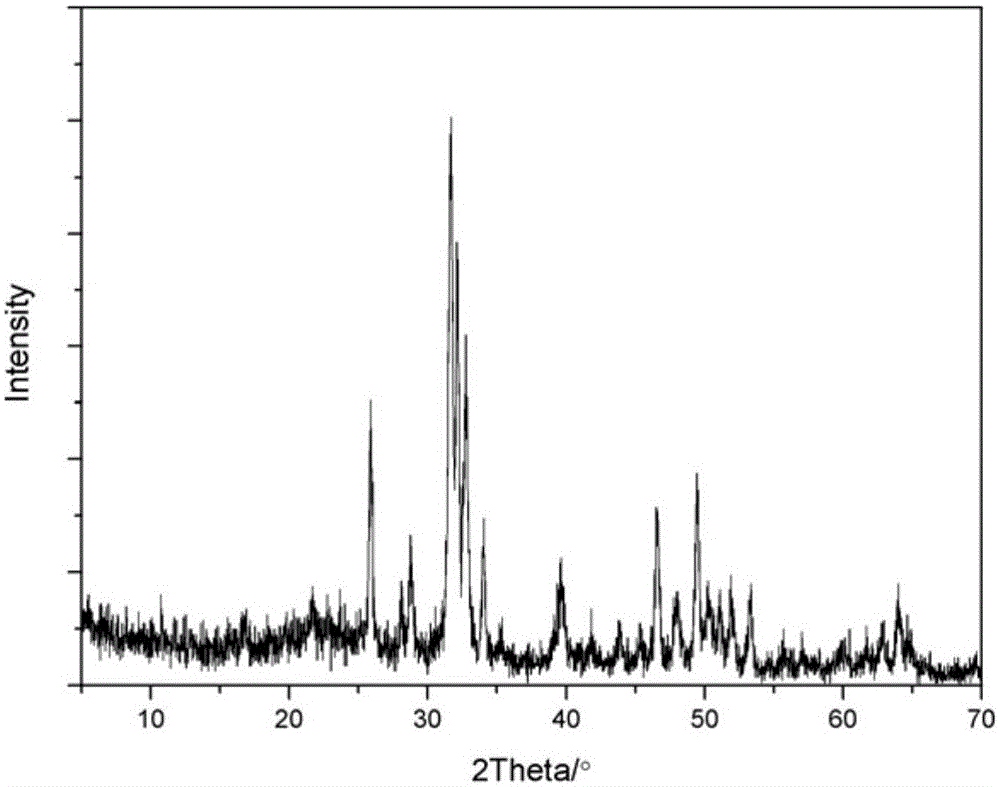

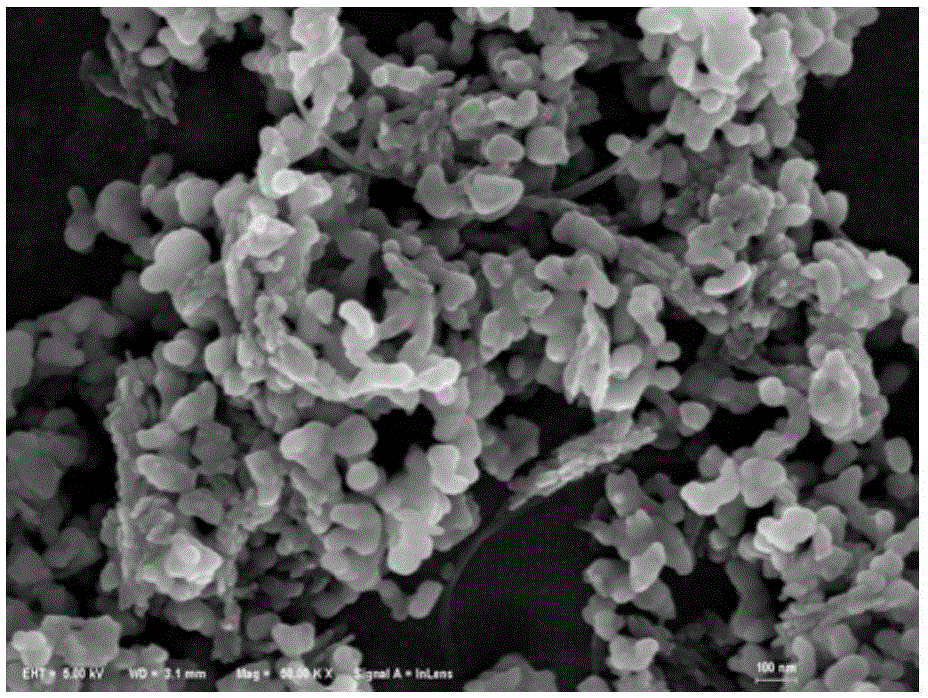

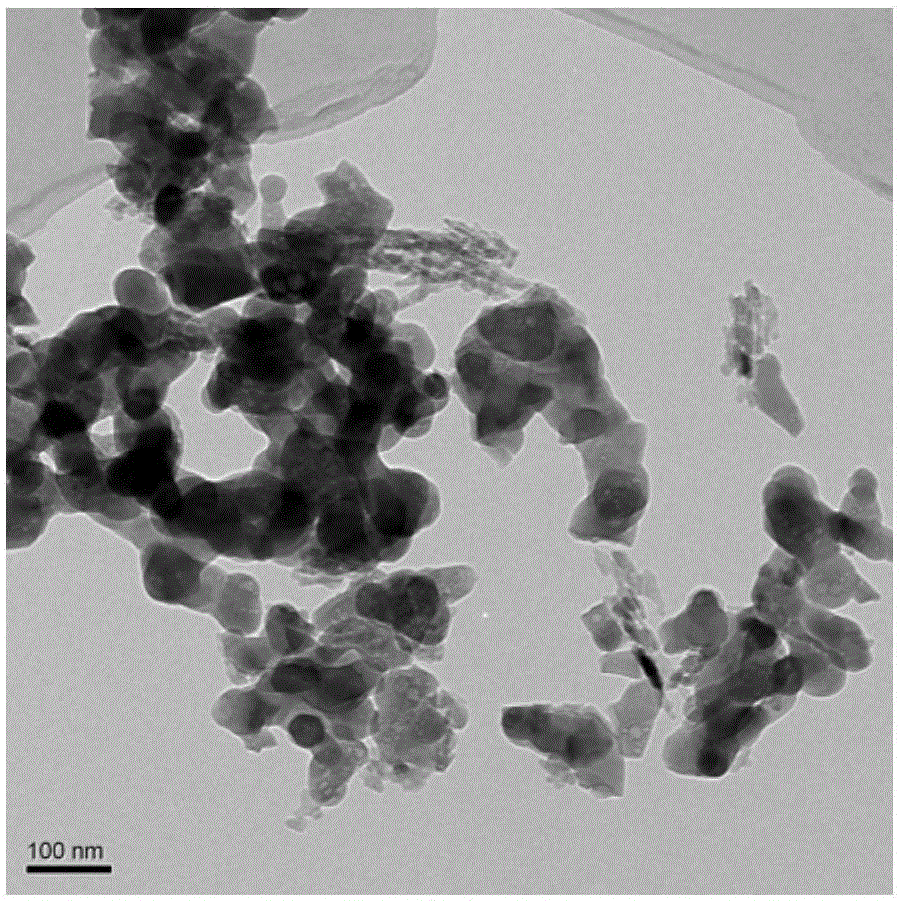

Rare-earth-doped calcium phosphate fluorescent nanoparticles, and preparation method and application thereof

A technology of rare earth doping and fluorescent nanotechnology, applied in biochemical equipment and methods, fluorescence/phosphorescence, chemical instruments and methods, etc., can solve problems such as difficult element ratio, uneven distribution of doped elements, and easy powder agglomeration. Achieve the effects of low synthesis temperature, high fluorescence intensity, and reduced agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, configure Ca(NO 3 ) 3 , Eu(NO 3 ) 3 and Gd(NO 3 ) 3 50ml of mixed solution, control Ca 2+ 、Eu 3+ and Gd 3+ The total concentration of is 0.0334mol / L, wherein (Eu+Gd) / (Eu+Gd+Ca) molar percentage is 4%, and the Eu / Gd molar ratio is Eu:Gd=2:2. According to the concentration of PAA after adding is 0.5mg / ml, accurately weigh 25mg of PAA, add to Ca(NO 3 ) 3 , Eu(NO 3 ) 3 and Gd(NO 3 ) 3 The mixed solution was sonicated with a high-energy ultrasonic probe for 4 minutes to obtain a colloidal solution. Then, configure (NH 4 ) 2 HPO 4 Aqueous solution 50ml, control PO 4 3- The concentration is 0.02mol / L. According to the molar ratio (Ca+Eu+Gd) / P=1.67, 50mL (NH 4 ) 2 HPO 4 Quickly pour the aqueous solution into the colloidal solution obtained above, stir and mix evenly, add dilute nitric acid to adjust the pH value to 3, and evaporate the obtained colloidal solution in a water bath at 80°C until its volume is reduced to 25ml to obtain a gel. Finally, ...

Embodiment 2

[0036] First, configure Ca(NO 3 ) 3 , Eu(NO 3 ) 3 and Tb(NO 3 ) 3 50ml of mixed solution, control Ca 2+ 、Eu 3+ and Tb 3+The total concentration is 0.1002mol / L, the molar percentage of (Eu+Tb) / (Eu+Tb+Ca) is 4%, and the molar ratio of Eu / Tb is Eu:Tb=2:2. According to the concentration after the addition of PAA is 0.3 mg / ml, 15 mg of PAA was quantitatively weighed, added to the mixed solution obtained above at room temperature, and sonicated with a high-energy ultrasonic probe for 4 minutes to obtain a colloidal solution. Then, configure (NH 4 ) 2 HPO 4 Aqueous solution, control PO 4 3- The molar concentration is 0.0668mo1 / L. According to the molar ratio (Ca+Eu+Tb) / P=1.5, 50mL (NH 4 ) 2 HPO 4 Quickly pour the aqueous solution into 50 mL of the colloidal solution obtained above, stir and mix evenly, add dilute nitric acid to adjust the pH value to 3, and evaporate water from the aforementioned colloidal solution until its volume shrinks to about 20 ml in a water ba...

Embodiment 3

[0038] First, configure Ca(NO 3 ) 3 , Eu(NO 3 ) 3 and Gd(NO 3 ) 3 50ml of mixed solution, control Ca 2+ 、Eu 3+ and Gd 3+ The total concentration is 0.0334mol / L, wherein (Eu+Gd) / (Eu+Gd+Ca) molar percentage is 3.5%, and the Eu / Gd molar ratio is Eu:Gd=2:1.5. According to the concentration of PAA after adding is 0.7mg / ml, accurately weigh 35mg of PAA, add to Ca(NO 3 ) 3 , Eu(NO 3 ) 3 and Gd(NO 3 ) 3 The mixed solution was sonicated with a high-energy ultrasonic probe for 4 minutes to obtain a colloidal solution. Then, configure (NH 4 ) 2 HPO 4 Aqueous solution 50ml, control PO 4 3- The concentration is 0.02mol / L. According to the molar ratio, 50mL (NH 4 ) 2 HPO 4 Quickly pour the aqueous solution into the colloidal solution obtained above, stir and mix evenly, add dilute nitric acid to adjust the pH value to 3, and evaporate the obtained colloidal solution in a water bath at 80°C until its volume is reduced to 25ml to obtain a gel. Finally, the obtained gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com