GH3030 high-temperature alloy as-cast metallographic etchant and preparing method and using method thereof

A technology of GH3030 and high-temperature alloy, which is applied in the field of metallographic corrosion liquid, can solve the problems of poor corrosion effect and unsatisfactory effect, and achieve the effect of improving product quality, improving product quality and product yield, and good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

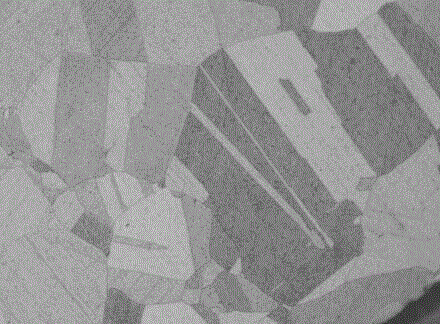

Image

Examples

Embodiment 1

[0034] A GH3030 superalloy as-cast metallographic corrosion solution, consisting of the following components: 22 mL of concentrated hydrochloric acid, 20 mL of water, and 4 g of copper sulfate, wherein the concentrated hydrochloric acid is analytically pure, with a mass fraction of 36%-38%.

[0035] When preparing the GH3030 superalloy as-cast metallographic corrosion solution, first weigh 4g of copper sulfate and pour it into an 80 mL beaker, then measure 20 mL of water and pour it into the beaker, then measure 22 mL of concentrated hydrochloric acid and pour it into the beaker , stir with a glass rod to completely melt the copper sulfate and let it stand for at least 10 minutes.

[0036] When using this GH3030 superalloy as-cast metallographic corrosion solution, the cross-section on the GH3030 superalloy forging produced by a certain enterprise is sampled earlier, and is cut into a metallographic sample of 15X15X15mm with a cutting machine, and the number is 1# sample and 2...

Embodiment 2

[0038] A GH3030 superalloy as-cast metallographic corrosion solution, consisting of the following components: 21 mL of concentrated hydrochloric acid, 21 mL of water, and 5 g of copper sulfate, wherein the concentrated hydrochloric acid is analytically pure, with a mass fraction of 36%-38%.

[0039] When preparing the GH3030 superalloy as-cast metallographic corrosion solution, first weigh 5g of copper sulfate and pour it into an 80 mL beaker, then measure 21 mL of water and pour it into the beaker, then measure 21 mL of concentrated hydrochloric acid and pour it into the beaker , stir with a glass rod to completely melt the copper sulfate and let it stand for at least 10 minutes.

[0040]When using this GH3030 superalloy as-cast metallographic corrosion solution, earlier the cross-section on the GH3030 superalloy forging produced by a certain enterprise was sampled, and cut into 15X15X15mm metallographic samples with a cutting machine, numbered as 3# sample and 4# sample; use...

Embodiment 3

[0042] A GH3030 superalloy as-cast metallographic corrosion solution is composed of the following components: concentrated hydrochloric acid 23mL, water 19mL, copper sulfate 3g, wherein the concentrated hydrochloric acid is analytically pure, and the mass fraction is 36%-38%.

[0043] When preparing the GH3030 superalloy as-cast metallographic corrosion solution, first weigh 3g of copper sulfate and pour it into an 80 mL beaker, then measure 19 mL of water and pour it into the beaker, then measure 23 mL of concentrated hydrochloric acid and pour it into the beaker , Stir with a glass rod, and let the copper sulfate stand still for at least 10 minutes after the copper sulfate is completely melted.

[0044] When using this GH3030 superalloy as-cast metallographic corrosion solution, earlier the cross-section on the GH3030 superalloy forging produced by a certain enterprise was sampled, and cut into 15X15X15mm metallographic samples with a cutting machine, numbered as 5# sample an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com