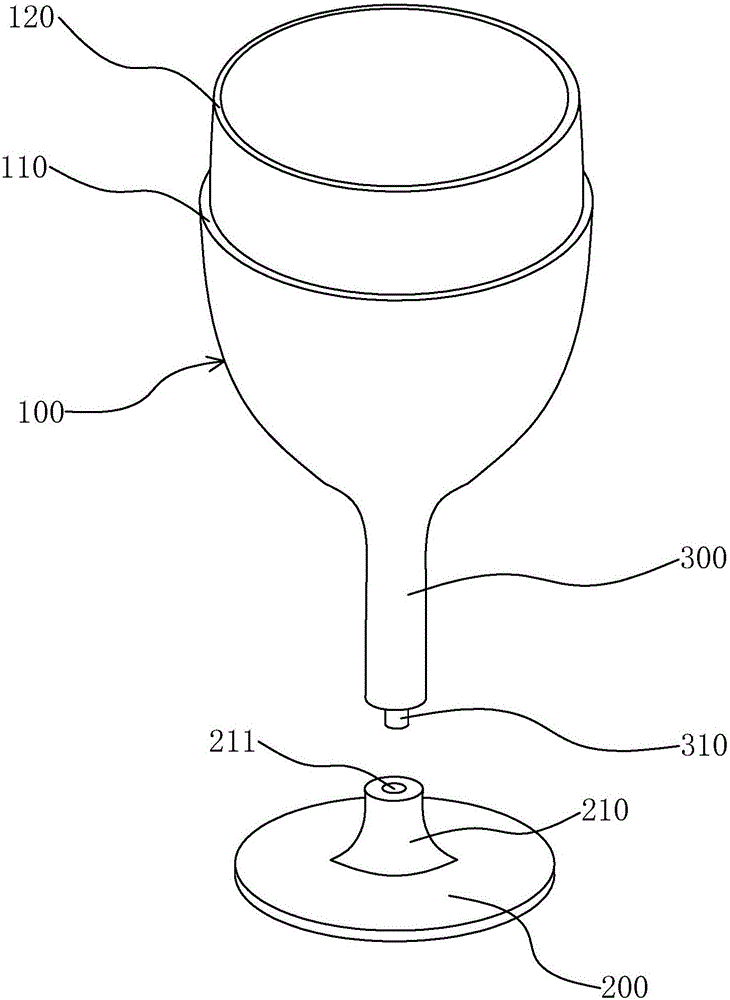

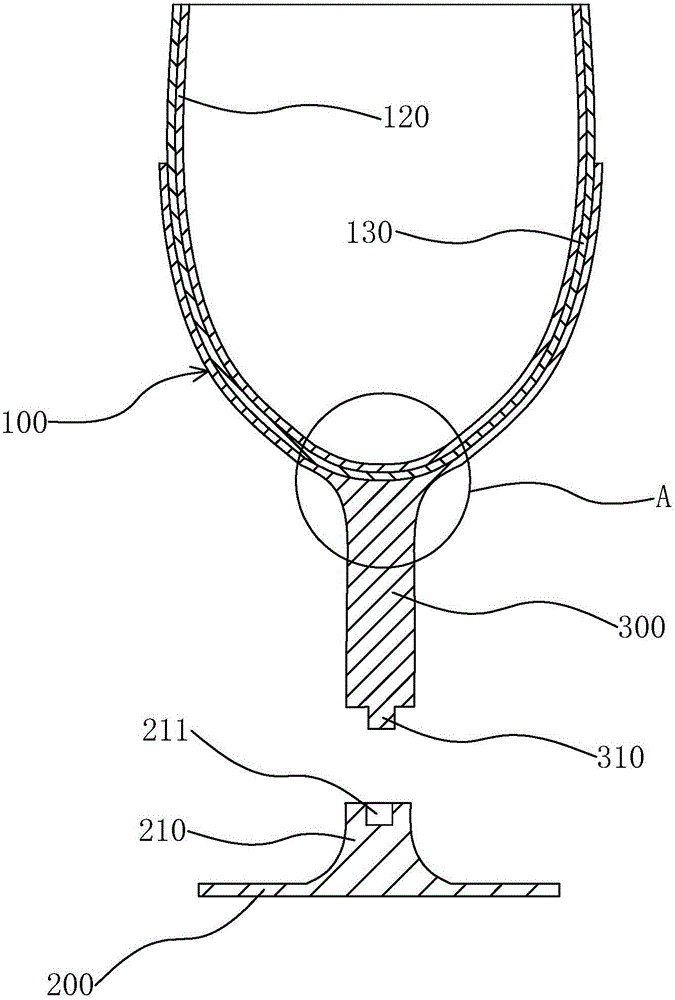

Double-color plastic cup and processing method thereof

A technology of two-color plastics and processing methods, which is applied in the direction of drinking water containers, etc., can solve the problems that the quality and sanitation of tableware cannot be guaranteed, the processing method of disposable tableware is simple and rough, and the color of the cup body is single, so as to prevent scald accidents and improve the final product quality. The effect of simple performance and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

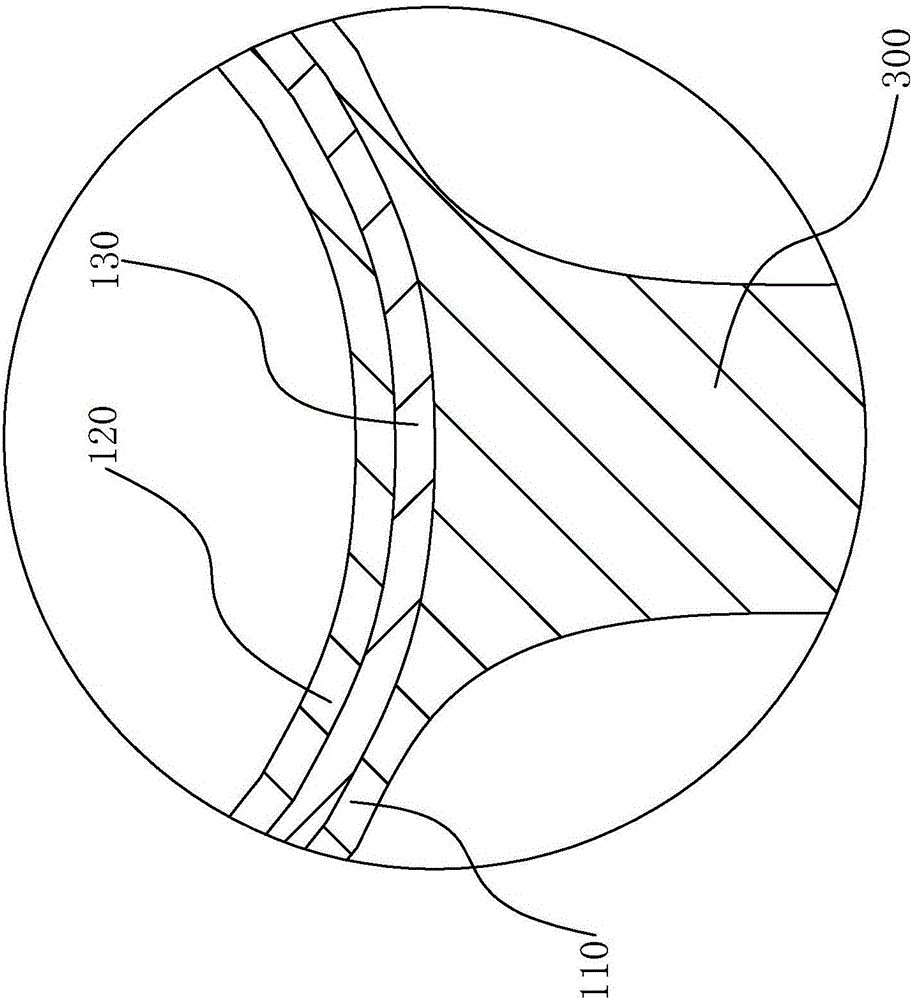

[0039] Add different toners to polystyrene-based plastics to make sheets of various colors, wherein the thickness of the sheet is 0.6mm, and two layers of sheets of different colors are stacked together;

[0040] The superimposed sheets are obtained through the injection molding process to obtain the cup body whose outer layer is connected to the pole; the heating temperature during the injection molding process is 230°C; injection pressure: injection pressure level 1: 35Mpa, injection pressure level 2: 88Mpa, Injection pressure level 3: 95Mpa, holding pressure 45Mpa; injection speed: injection rate level 1: 18mm / s, injection rate level 2: 65mm / s, injection rate level 3: 70mm / s, holding speed: 22mm / s; injection time: Injection 6s, cooling 15s, cycle 40s;

[0041] Insert the mounting column at the bottom of the pole into the mounting hole on the base to process the finished two-color plastic cup.

Embodiment 2

[0043] Add different toners to PP polypropylene plastics to make sheets of various colors. The thickness of the sheets is 0.5mm. The sheets of different colors are stacked together to form the outer layer, the reinforcement layer and the inner layer. The surface layer and the inner surface layer have different colors; wherein, the PP type polypropylene plastic includes the following components by weight: PP resin: 60 parts, nano-SiO 2 : 5 parts, Nano CaCO 3 : 4 parts, compound antibacterial and anti-mold auxiliary agent: 1.5 parts, processing aid: 4 parts, antioxidant: 0.8 part; the compound anti-bacterial and anti-mold auxiliary agent is a nano-silver ion antibacterial agent, and the processing aid includes 1 part of talcum powder, 1 part of fatty acid amide, 2 parts of PP-g-ST, and the antioxidant is 2,6-di-tert-butylphenol.

[0044] The superimposed sheets are obtained through the injection molding process to obtain the cup body whose outer layer is connected to the pole; ...

Embodiment 3

[0047] Add different toners to PP polypropylene plastic to make sheets of various colors. The thickness of the sheet is 0.4mm, and the three layers of sheets are stacked together to form the outer layer, the reinforcement layer and the inner layer. The outer layer Different from the color of the inner surface layer; wherein, the PP type polypropylene plastic includes the following components by weight: PP resin: 50 parts, nano-SiO 2 : 8 parts, Nano CaCO 3 : 5 parts, compound antibacterial and anti-mold auxiliary agent: 2 parts, processing aid: 6 parts, antioxidant: 0.8 part; compound anti-bacterial and anti-mold auxiliary agent is 1 part of nano-silver ion antibacterial agent, 1 part of vanillin compound, The processing aid is 1.5 parts of silane coupling agent, 1.5 parts of organosilicon compound, 3 parts of compatibilizer PP-g-MAH, 0.3 part of antioxidant 1010, and 0.5 part of antioxidant 1076.

[0048] The superimposed sheets are obtained through the injection molding proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com