A kind of preparation method of dermal tissue bionic sponge

A tissue and dermis technology, applied in the field of medical biomimetic materials, can solve problems such as promoting functional dermal tissue regeneration, secondary surgery, virus transmission, etc., to promote adhesion and proliferation activity, and reduce biodegradation speed. , the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

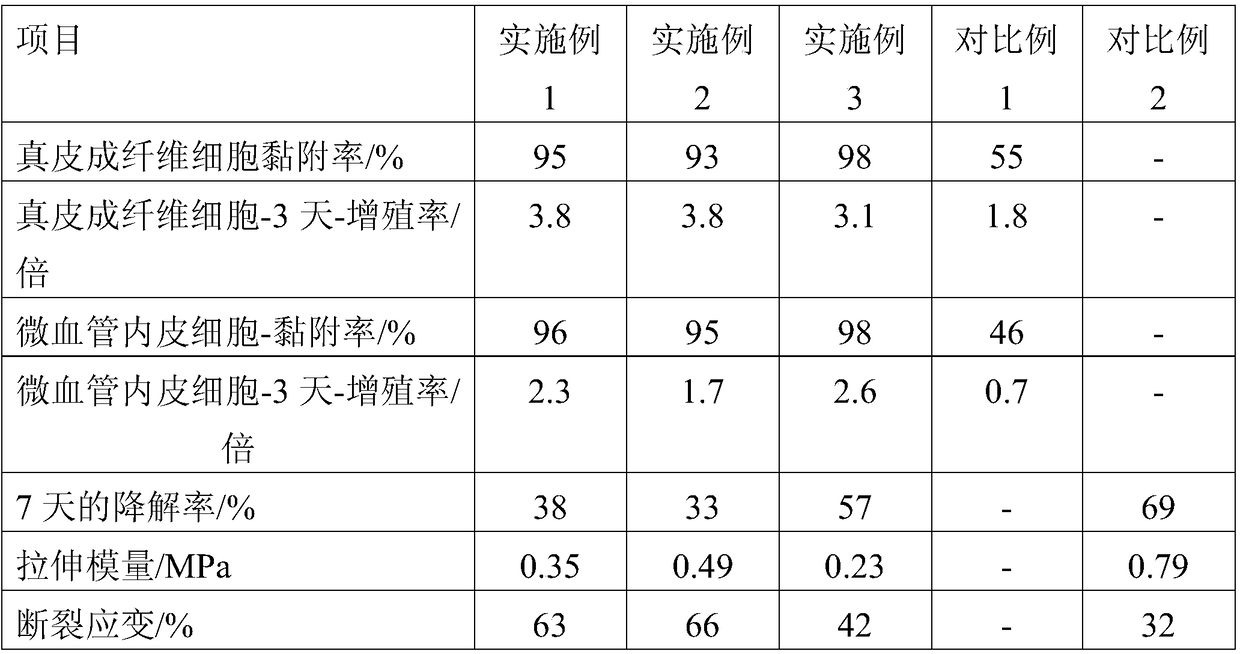

Embodiment 1

[0026] (1) Put 10g of silkworm cocoons in 500ml of 0.02M Na 2 CO 3 Boiling in an aqueous solution for 30 minutes, then rinsing with deionized water for 3 times to obtain silk fibroin fibers; then placing silk fibroin fibers in 10ml of 9.3M lithium bromide solution and dissolving at 37°C to obtain silk protein lithium bromide solution; Finally, the obtained solution was dialyzed in a dialysis box with a molecular weight cut-off of 3500 Da for 3 days to obtain an aqueous silk protein solution, and the mass percentage concentration of the solution was adjusted to 5%;

[0027] (2) Mix the silk protein solution prepared in step (1) with the collagen solution with a mass percent concentration of 1.5% at a volume ratio of 7:10 at 37° C. Shake for 5 minutes until the mixture is uniform, then centrifuge for 3 minutes at a centrifugal force of 1500g to remove the air bubbles in the solution;

[0028] (3) The mixed solution after step (2) centrifugation is transferred in the polytetraf...

Embodiment 2

[0033] (1) Put 10g silkworm cocoons in 500ml of 1M Na 2 CO 3 Boiling in an aqueous solution for 30 minutes, then rinsing with deionized water for 3 times to obtain silk fibroin fibers; then placing silk fibroin fibers in 10ml of 10M lithium bromide solution and dissolving at 37°C to obtain silk protein lithium bromide solution; finally After dialysis of the obtained solution in a dialysis box with a molecular weight cut-off of 3500 Da for 3 days, an aqueous silk protein solution was obtained, and the mass percent concentration of the solution was adjusted to 5%;

[0034] (2) Mix the silk protein solution prepared in step (1) with the collagen solution with a mass percent concentration of 1.5% at a volume ratio of 57:10 at 37° C. Shake for 5 minutes until the mixture is uniform, then centrifuge for 3 minutes at a centrifugal force of 1500g to remove the air bubbles in the solution;

[0035] (3) The mixed solution after step (2) centrifugation is transferred in the polytetrafl...

Embodiment 3

[0039] (1) Put 10g silkworm cocoons in 500ml of 0.05M Na 2 CO 3 Boiling in an aqueous solution for 30 minutes, then rinsing with deionized water for 3 times to obtain silk fibroin fibers; then placing silk fibroin fibers in 10ml of 15M lithium bromide solution and dissolving at 37°C to obtain silk protein lithium bromide solution; finally After dialysis of the obtained solution in a dialysis box with a molecular weight cut-off of 3500 Da for 3 days, an aqueous silk protein solution was obtained, and the mass percent concentration of the solution was adjusted to 5%;

[0040] (2) Mix the silk protein solution prepared in step (1) with the collagen solution with a mass percent concentration of 1.5% at a volume ratio of 0.4:10 at 37° C. Shake for 5 minutes until the mixture is uniform, then centrifuge for 3 minutes at a centrifugal force of 1500g to remove the air bubbles in the solution;

[0041] (3) The mixed solution after step (2) centrifugation is transferred in the polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com