Method for producing biomass charcoal dye adsorbent

A production method and technology of biomass charcoal, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as low economic benefits, and achieve increased added value, good adsorption performance, and improved adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

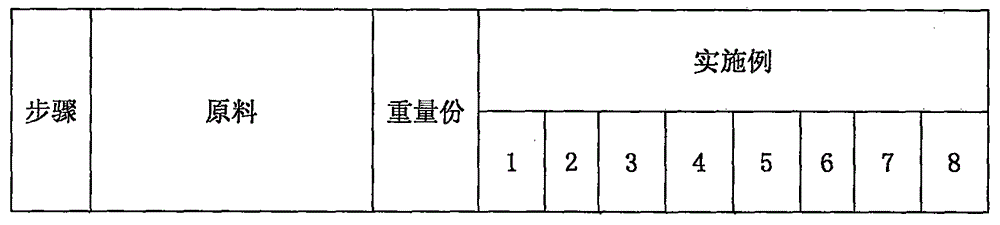

Embodiment 1

[0018] Embodiment 1 (contrasted with corresponding embodiment 1 and the proportioning value by weight in the table above), is prepared according to the following steps:

[0019] (1) raw materials including bamboo chips, bamboo slices, scraps, bamboo silk are pulverized into 60-80 order bamboo powder;

[0020] (2) Preparation of hydrothermal bamboo charcoal: 20 parts by weight of 60-80 mesh bamboo powder and 7 parts by weight of anhydrous ferric chloride are placed in 100 parts by weight of water, stirred and mixed at room temperature In a lined stainless steel reaction kettle, react at 180°C for 12 hours, cool naturally, filter with suction, wash until neutral, and then dry to obtain hydrothermal bamboo charcoal;

[0021] (3) Preparation of activated hydrothermal bamboo charcoal: mix the hydrothermal bamboo charcoal obtained in step (2) with 2 parts by weight of sodium hydroxide and 100 parts by weight of water, stir at room temperature for 1 hour, suction filter, wash until n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com