Production method for hydrothermal bamboo based biomass carbon adsorption material catalyzed by inorganic strong acid

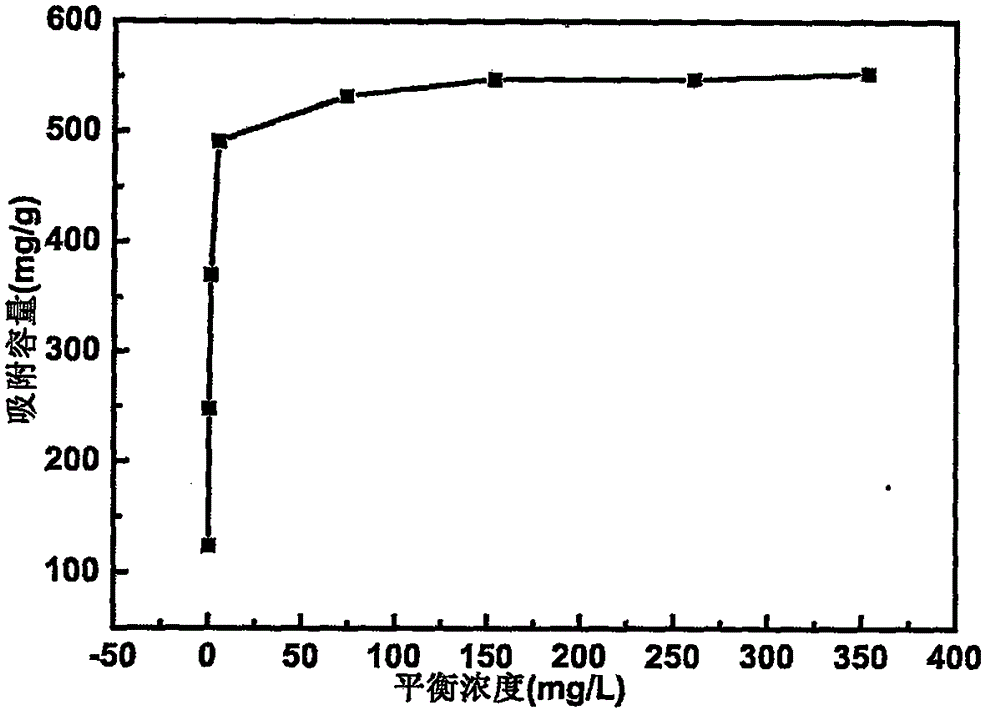

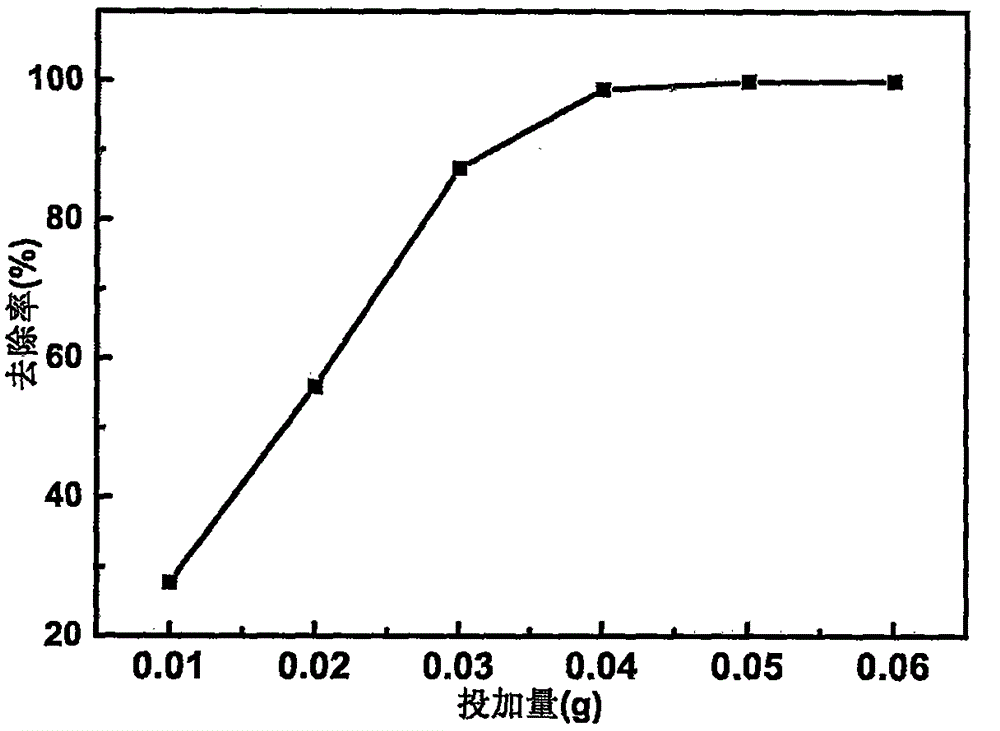

A technology of inorganic strong acid and biochar, which is applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of low utilization rate of bamboo resources, improve adsorption capacity, increase added value, and be good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 (corresponding embodiment 1 and the proportioning value by weight in contrasting table above), prepare as follows according to the following steps:

[0019] (1) Grinding bamboo chips, bamboo chips, leftovers, bamboo silk, etc. into 60-80 meshes;

[0020] (2) Preparation of hydrothermal bamboo charcoal: the 60-80 mesh bamboo powder of 60 parts by weight and the concentration of 21 parts by weight of 37% concentrated hydrochloric acid are placed in 220 parts by weight of water, stirred and mixed evenly at room temperature and then placed in a polytetrafluoroethylene In a stainless steel reaction kettle lined with ethylene, react at 200°C for 15 hours, cool naturally, filter with suction, wash until neutral, and then dry to obtain hydrothermal bamboo charcoal;

[0021] (3) Preparation of activated hydrothermal bamboo charcoal: mix the hydrothermal bamboo charcoal obtained in step (2) with 3.6 parts by weight of sodium hydroxide and 240 parts by weight of water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com