Fabrication method of thin film transistor and micro-nano composite jet machine

A technology of composite jetting machine and jetting mechanism, which is applied in the direction of additive manufacturing, manufacturing tools, processing irradiation arrangement, etc., can solve the problems of application limitation, low production efficiency, and low resolution of feature size, and achieve the goal of overcoming inaccurate positioning and high propulsion Accuracy, to meet the effect of large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] What the present invention discloses is a method for manufacturing a thin film transistor. The method uses micron and nanoscale droplet compound spraying technology on the base material, and sprays out each structural feature of the transistor layer by layer according to the structure and material of the thin film transistor, and when The nano-jet method is used when the characteristic size of the transistor is smaller than the micro-jet size or fine spray is required, otherwise the micro-jet method is used.

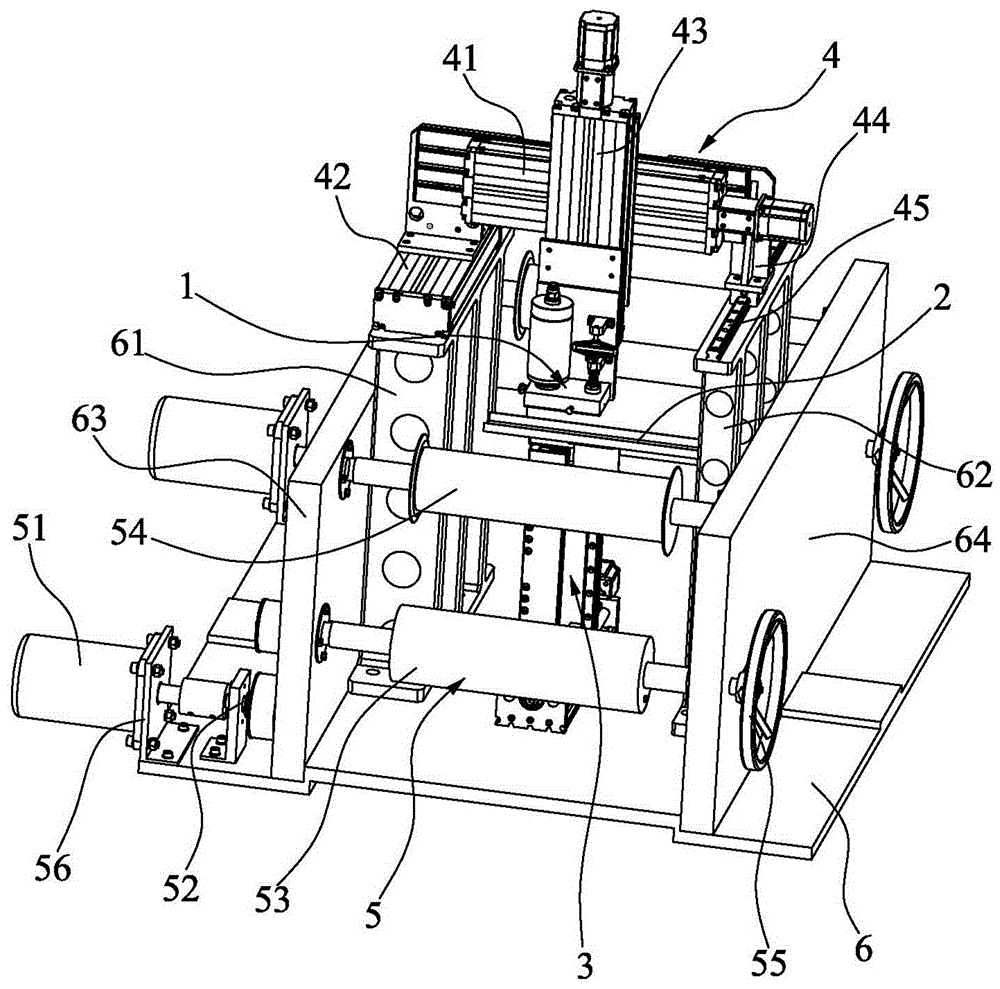

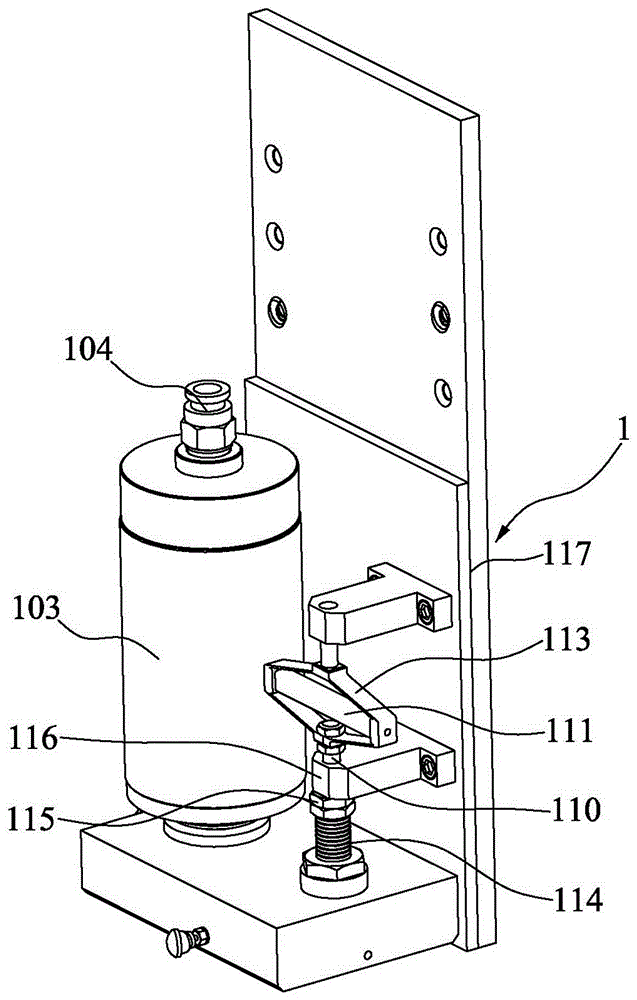

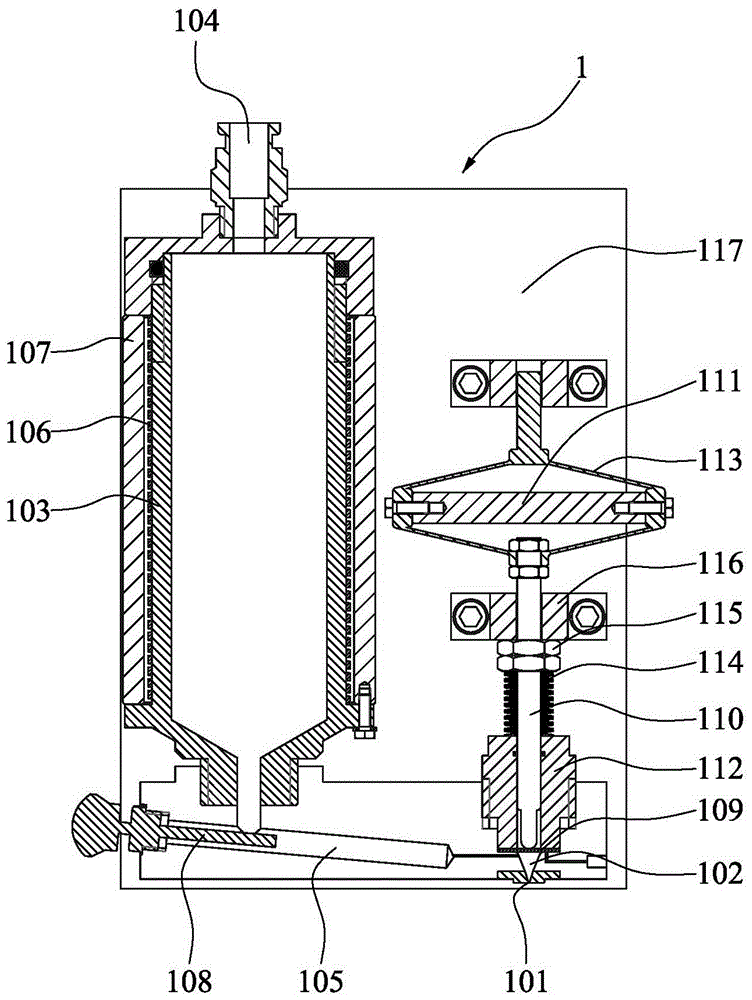

[0030] In order to realize the above method, the existing micro-jet device and nano-scale electrofluid jet device can be used for complex switching. However, due to the different principles, equipment and nozzle structures of existing micro-jet and nano-jet, the efficiency is low and the positioning is inaccurate when spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com