Gold/poly(o-aminophenol), gold/poly(p-phenylenediamine) and gold/poly(o-phenylenediamine) nanoparticles as well as preparation method and application thereof

A technology of poly-o-aminophenol and poly-o-phenylenediamine, which is applied to agglomerates, can solve the problems of difficult purification, small molecular weight, poor reproducibility of detection and analysis methods, etc., and achieves the effect of simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

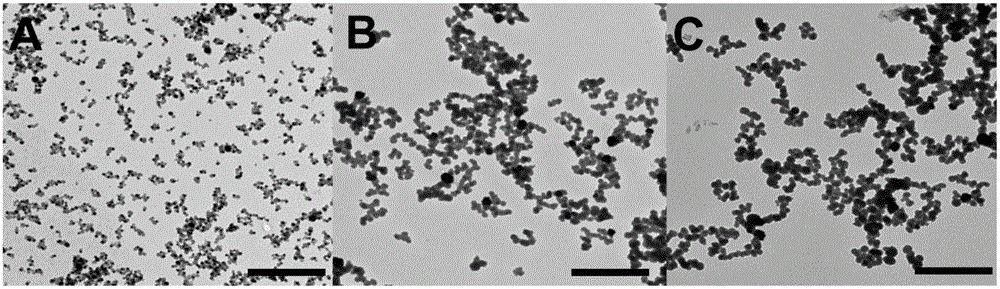

[0027] 1. Preparation of gold / poly-o-aminophenol composite nanoparticles

[0028] Add 1mL of 0.1M hydrochloric acid to 3mL of ultrapure water and 0.5mL of ethanol solution, then add 5mg of o-aminophenol, and stir at 20°C for 1h. Then, 970 μL of 2% chloroauric acid was quickly added, reacted for 4 hours, the product was centrifuged, and washed with ultrapure water.

[0029] 2. Preparation of gold / poly-p-phenylenediamine composite nanoparticles

[0030] Add 2mL of 0.5M citric acid to 3mL of ultrapure water and 3mL of ethanol solution, then add 5mg of p-phenylenediamine, and stir at 30°C for 1h. Then, 970 μL of 2% chloroauric acid was quickly added, reacted for 4 hours, the product was centrifuged, and washed with ultrapure water.

[0031] 3. Preparation of gold / poly-o-phenylenediamine composite nanoparticles

[0032] Add 1mL of 1M hydrochloric acid to 5mL of ultrapure water, and then add 5mg of o-phenylenediamine, thus restricting its application on sensors. Stir for 10 min....

Embodiment 2

[0034] 1. Preparation of gold / poly-o-aminophenol composite nanoparticles

[0035] Add 3mL of 1M hydrochloric acid to 6mL of ultrapure water and 9mL of ethanol solution, then add 2mg of o-aminophenol, and stir at 20°C for 45min. Then, 6.45 mL of 3% chloroauric acid was quickly added, reacted for 4 hours, the product was centrifuged, and washed with ultrapure water.

[0036] 2. Preparation of gold / poly-p-phenylenediamine composite nanoparticles

[0037] Add 6mL of 1M citric acid to 1mL of ultrapure water and 1mL of ethanol solution, then add 5mg of p-phenylenediamine, and stir at 20°C for 1h. Then, 6.45 mL of 3% chloroauric acid was quickly added, reacted for 4 hours, the product was centrifuged, and washed with ultrapure water.

[0038] 3. Preparation of gold / poly-o-phenylenediamine composite nanoparticles

[0039] Add 2mL of 1M hydrochloric acid to 8mL of ultrapure water, then add 5mg of o-phenylenediamine, and stir at 40°C for 10min. Then, 6.45 mL of 3% chloroauric acid w...

Embodiment 3

[0041] 1. Preparation of gold / poly-o-aminophenol composite nanoparticles

[0042] Add 2mL of 0.5M hydrochloric acid to 2mL of ultrapure water and 3mL of ethanol solution, then add 2mg of o-aminophenol, and stir at 30°C for 45min. Then, 3.87mL of 10% chloroauric acid was quickly added, reacted for 4h, the product was centrifuged, and washed with ultrapure water.

[0043] 2. Preparation of gold / poly-p-phenylenediamine composite nanoparticles

[0044] Add 1mL of 0.5M citric acid to 1.5mL of ultrapure water and 1.5mL of ethanol solution, then add 2mg of p-phenylenediamine, and stir at 30°C for 1h. Then, 3.87mL of 10% chloroauric acid was quickly added, reacted for 4h, the product was centrifuged, and washed with ultrapure water.

[0045] 3. Preparation of gold / poly-o-phenylenediamine composite nanoparticles

[0046]Add 1mL of 0.5M hydrochloric acid to 2mL of ultrapure water, then add 2mg of o-phenylenediamine, and stir at 30°C for 10min. Then, 3.87mL of 10% chloroauric acid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com