Denitrification method for waste water low in carbon nitrogen ratio

A low-carbon nitrogen ratio, denitrification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor denitrification effect and improve the denitrification rate , the effect of improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Wastewater water quality: In this embodiment, the domestic sewage reactor in the residential area is used as influent, the chemical oxygen demand is 235.05mg / L, the average concentration of nitrogen is 58.10mg / L, the average carbon-nitrogen ratio of influent is 3.9:1, and the pH Value = 7.5.

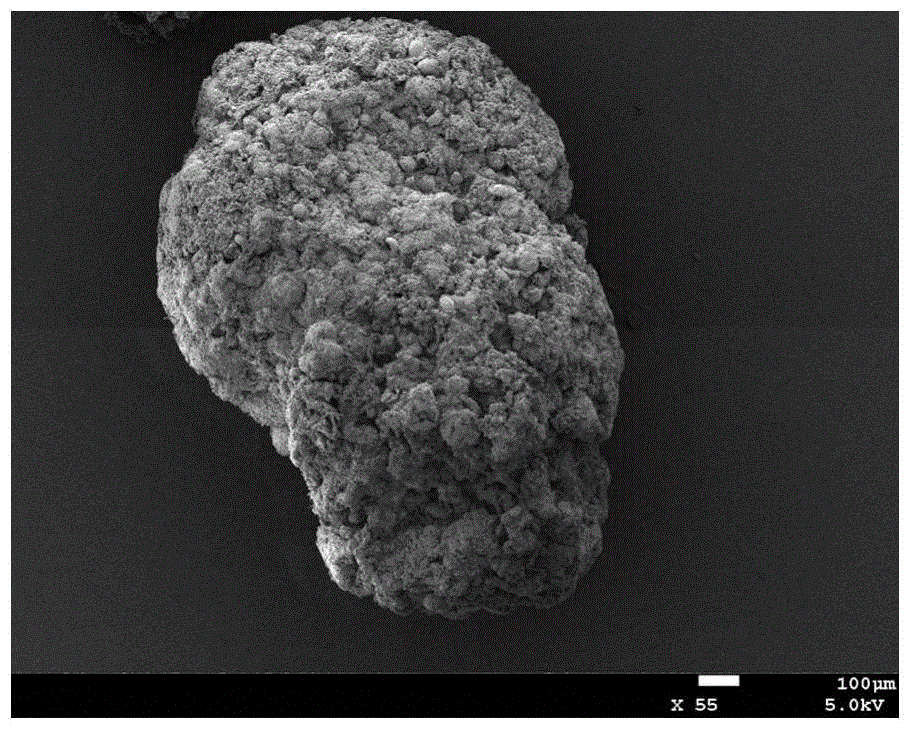

[0059] A cuboid-shaped SBR reactor is adopted, with a height of 20cm, a length of 10cm, and an effective volume of 1.5L; the middle and lower parts of the reactor are equipped with drains and sludge outlets. Inoculate the activated sludge in the SBR reactor, and add 88mg / L of CaCl to the reactor 2 , the concentration of activated sludge in the reactor after inoculation was 3730mg / L.

[0060] There are 2 cycles in the reactor every day, and each cycle includes 4 sections of water intake, aeration, static sedimentation and drainage, of which water intake is 5 minutes; aeration is 400 minutes, and the aeration rate is 300mL / min; drainage is 5 minutes, and the discharge volume per cy...

Embodiment 2

[0072] Wastewater water quality: In this embodiment, the domestic sewage reactor in the residential area is used as influent, the chemical oxygen demand is 235.05mg / L, the average concentration of nitrogen is 58.10mg / L, the average carbon-nitrogen ratio of influent is 3.9:1, and the pH Value = 7.5.

[0073] A cuboid-shaped SBR reactor is adopted, with a height of 20cm, a length of 10cm, and an effective volume of 1.5L; the middle and lower parts of the reactor are equipped with drains and sludge outlets. Inoculate the activated sludge in the SBR reactor, and add 90mg / L CaCl to the reactor 2, the concentration of activated sludge in the reactor after inoculation was 3630mg / L.

[0074] There are 2 cycles in the reactor every day, and each cycle includes 4 sections of water intake, aeration, static sedimentation and drainage, of which water intake is 6 minutes; aeration is 450 minutes, and the aeration rate is 350mL / min; drainage is 6 minutes, and the discharge volume per cycle ...

Embodiment 3

[0080] Waste water quality: In this embodiment, the campus domestic sewage is used as the reactor feed water, the chemical oxygen demand is 240.5 mg / L, the average concentration of nitrogen is 70.3 mg / L, the average carbon-nitrogen ratio of feed water is 3.42:1, and the pH value is 7.4.

[0081] A cylindrical SBR reactor with a height-to-diameter ratio of 2.5:1 was used, with an effective volume of 1.0 L and an average reaction temperature of 28 °C.

[0082] Inoculate the activated sludge in the SBR reactor, and add 88mg / L of CaCl to the reactor 2 , the concentration of activated sludge in the reactor after inoculation was 3730mg / L.

[0083] There are 2 cycles in the reactor every day, and each cycle includes 4 sections of water intake, aeration, static sedimentation and drainage, of which water intake is 5 minutes; aeration is 400 minutes, and the aeration rate is 300mL / min; drainage is 5 minutes, and the discharge volume per cycle 80% of the effective volume. In the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com