Nanocrystalline enhanced tungsten oxide electrochromic film and preparation method thereof

An electrochromic and nanocrystalline technology, applied in the field of inorganic functional materials, can solve the problems of short cycle life of electrochromic materials, lack of near-infrared modulation ability, slow response rate of discoloration of large-sized materials, etc., to improve electrochromic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of "ITO nanocrystal-WO 3 Amorphous" electrochromic film:

[0025] Take 0.9914g of tungsten chloride, 0.0477g of indium nitrate, and 0.0046g of tin nitrate, dissolve them in 49.5mL of methanol, add 0.5mL of deionized water to it, and stir at room temperature for 2 hours to fully dissolve, and then obtain tungsten, indium, The composite sol of tin; the obtained composite sol is uniformly coated on the transparent conductive oxide glass substrate by dipping or spin-coating technology to form a gel film, dried at 150°C for 10 minutes, and then placed in a heat treatment furnace 200 ~ 300 ℃ in an oxygen atmosphere for 1h, then take it out, air-cooled to room temperature to get "ITO nanocrystal-WO 3 Amorphous" dual-phase composite thin films.

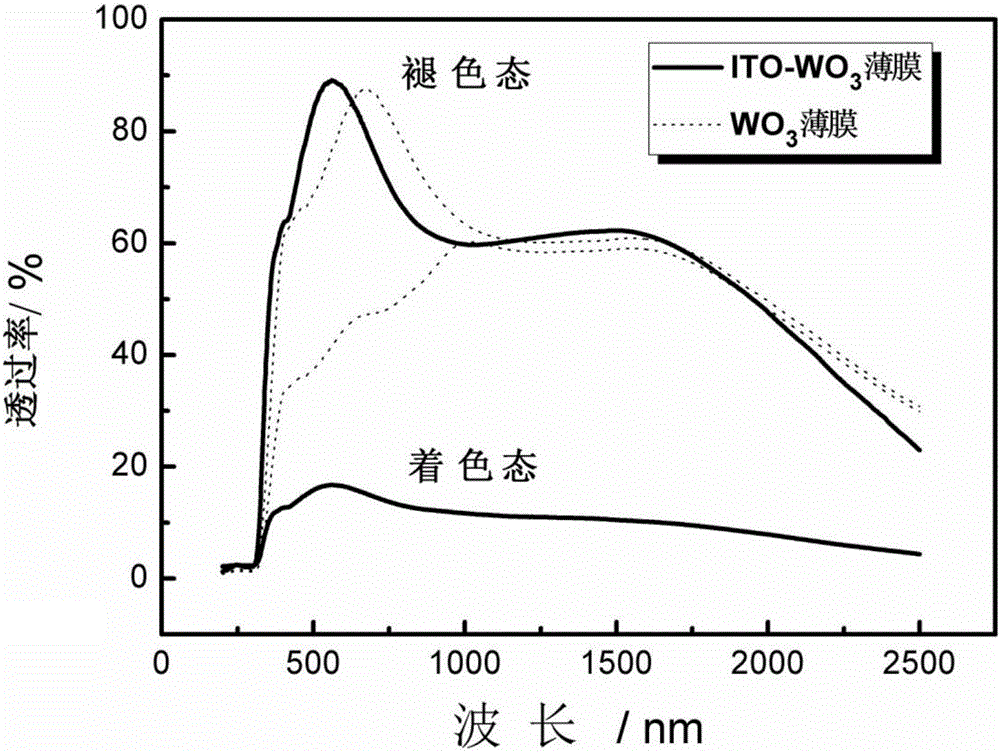

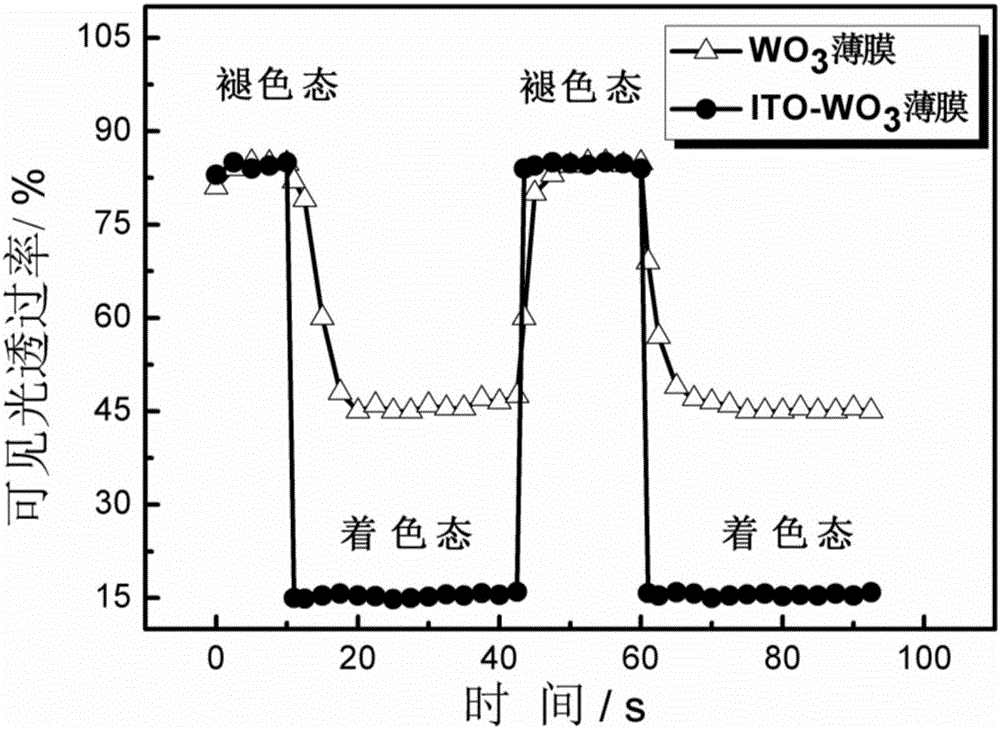

[0026] The transmittance curves of the colored state and the faded state of the film obtained in this embodiment are as follows: figure 1 As shown, the optical modulation contrast ΔT% in the visible light band is 70%; th...

Embodiment 2

[0028] Preparation of "ITO nanocrystal-WO 3 Amorphous" electrochromic film:

[0029] Take 3g of tungsten chloride, 0.5777g of indium nitrate, and 0.055g of tin nitrate, dissolve them in 49.5mL of ethanol, add 0.5mL of deionized water to it, and stir at room temperature for 2 hours to dissolve fully, and then get tungsten, indium, and tin The composite sol of the composite sol; the obtained composite sol is evenly coated on the transparent conductive oxide glass substrate by dipping or spin-coating technology to form a gel film. ~300°C in an oxygen atmosphere for 1 h, then take it out, and air cool to room temperature to obtain "ITO nanocrystal-WO 3 Amorphous" dual-phase composite thin films.

[0030] The film obtained in this embodiment has an optical modulation contrast ΔT% in the visible light band of 65%; an optical modulation contrast ΔT% in the 1200nm wavelength band is 53%; 100×100mm 2 The color change response time of the film is 1s, and after 2000 times of coloring ...

Embodiment 3

[0032] Preparation of "ITO nanocrystal-WO 3 Amorphous" electrochromic film:

[0033] Take 2g of tungsten chloride, 0.1527g of indium nitrate, and 0.0147g of tin nitrate, and dissolve them in 49.5mL of ethylene glycol methyl ether, add 0.5mL of deionized water to it, and stir at room temperature for 2 hours to fully dissolve to obtain tungsten-containing , indium, and tin composite sol; the resulting composite sol is uniformly coated on a transparent conductive oxide glass substrate by dipping or spin coating technology to form a gel film, dried at 150°C for 10 minutes, and then placed in a heat treatment The furnace was kept in an oxygen atmosphere at 200-300 °C for 1 h, then it was taken out, and air-cooled to room temperature to obtain "ITO nanocrystal-WO 3 Amorphous" dual-phase composite thin films.

[0034] The film obtained in this embodiment has an optical modulation contrast ratio ΔT% in the visible light band of 72%, an optical modulation contrast ratio ΔT% in the 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com