Extracting and separating method for various active ingredients of coix seeds

A technology of active ingredients and separation methods, which is applied in the field of extraction and separation of various active ingredients of coix seed, can solve the problems of destroying the active structure of coix seed polysaccharides, waste of resources, etc., and achieve the effects of avoiding solvent residue, low material consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

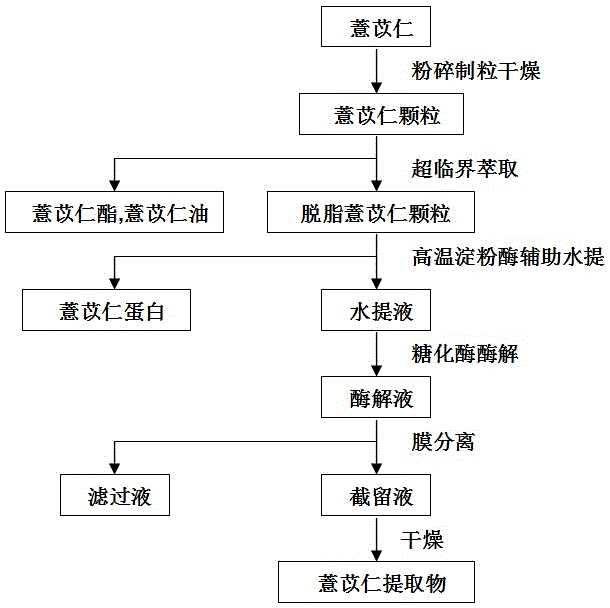

Method used

Image

Examples

Embodiment 1

[0036] 1. 10kg of coix seed is crushed and sieved to 60 mesh, added with 5kg of purified water for wet granulation, sieved to 20 mesh and then dried. 2 Extraction technology for extraction: the pressure of the extraction kettle is 25Mpa, the temperature is 40°C, the pressure of the separation kettle is 8Mpa, the temperature is 45°C, the flow rate is 110L / h, and the extraction time is 4h, 8.80kg of defatted coicis granules and 46g of coixene ester (yield 0.46%, purity 90.10%) and coix seed oil 0.502kg (yield 5.02%);

[0037] 2. Add 8.80 kg of defatted coix seed granules to 100 kg of purified water, 5 g of high-temperature amylase, extract at 95°C for 1 hour, and filter to obtain 105 kg of water extract and coix seed protein. The weight of coix seed protein after drying is 2.25 kg (yield 22.5%, purity 55.83%);

[0038] 3. Use hydrochloric acid to adjust the pH of 105kg of water extract to 4.0, add 5g of glucoamylase, enzymolyze at 65°C for 1 hour, and filter to obtain 105kg of ...

Embodiment 2

[0042] 1. 10kg of coix seed is crushed and sieved to 100 mesh, added with 4kg of purified water for wet granulation, sieved to 20 mesh and dried, and supercritical CO 2 Extraction technology for extraction: the pressure of the extraction kettle is 25Mpa, the temperature is 45°C, the pressure of the separation kettle is 8Mpa, the temperature is 40°C, the flow rate is 120L / h, and the extraction time is 3h, 8.85kg of defatted coicis granules and 45g of coixene ester (yield 0.45%, Purity 90.12%) [3] and coix seed oil 0.471kg (yield 4.71%);

[0043] 2. Add 8.85 kg of defatted coix seed granules to 100 kg of purified water, 5 g of high-temperature amylase, extract at 90°C for 2 hours, filter to obtain 106 kg of water extract and coix seed protein, and the weight of coix seed protein after drying is 2.15 kg (yield 21.5%, purity 57.70%) [4] ;

[0044] 3. Use hydrochloric acid to adjust the pH of 106 kg of water extract to 4.2, add 10 g of glucoamylase, enzymatically hydrolyze at 65...

Embodiment 3

[0048] 1. 10kg of coix seed is crushed and sieved to 80 mesh, added with 6kg of purified water for wet granulation, sieved to 10 mesh and then dried. 2 Extraction technology for extraction: the pressure of the extraction kettle is 25Mpa, the temperature is 40°C, the pressure of the separation kettle is 8Mpa, the temperature is 40°C, the flow rate is 120L / h, and the extraction time is 4h, 8.87kg of defatted coicis granules and 54g of coixene ester (yield 0.54%, Purity 89.97%) [3] and coix seed oil 0.520kg (yield 5.20%);

[0049] 2. Add 8.87kg of defatted coix seed granules to 100kg of purified water, 10g of high-temperature amylase, extract at 95°C for 2 hours, filter to obtain 105kg of water extract and coix seed protein, and the weight of coix seed protein after drying is 2.36kg (yield: 23.6%, purity: 52.94%) ) [4] ;

[0050] 3. Use hydrochloric acid to adjust the pH of 105 kg of water extract to 4.1, add 5 g of glucoamylase, enzymolyze at 60 ° C for 2 hours, and filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com