Method for improving fermentation efficiency of anaerobic qi-eating microorganisms

A microbial fermentation and microbial technology, applied in the direction of fermentation, can solve the problems of low growth concentration, hinder the application of microbial fermentation technology, etc., and achieve the effect of improving biomass accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

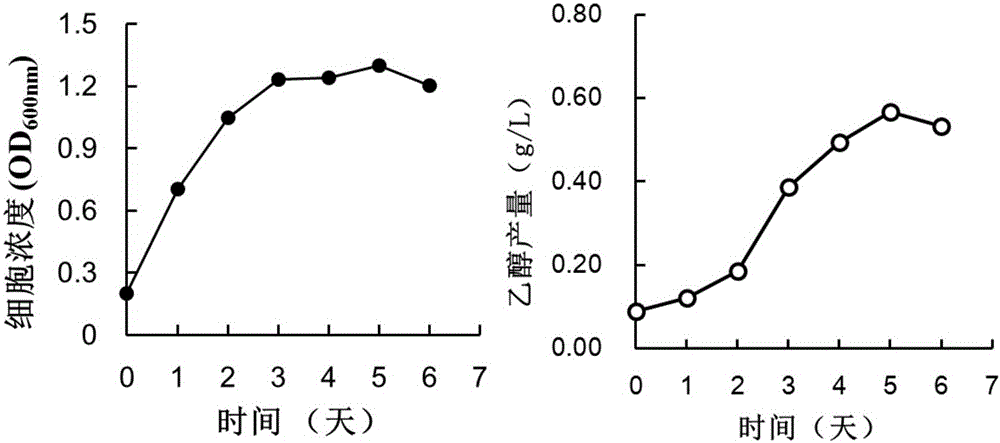

Embodiment 1

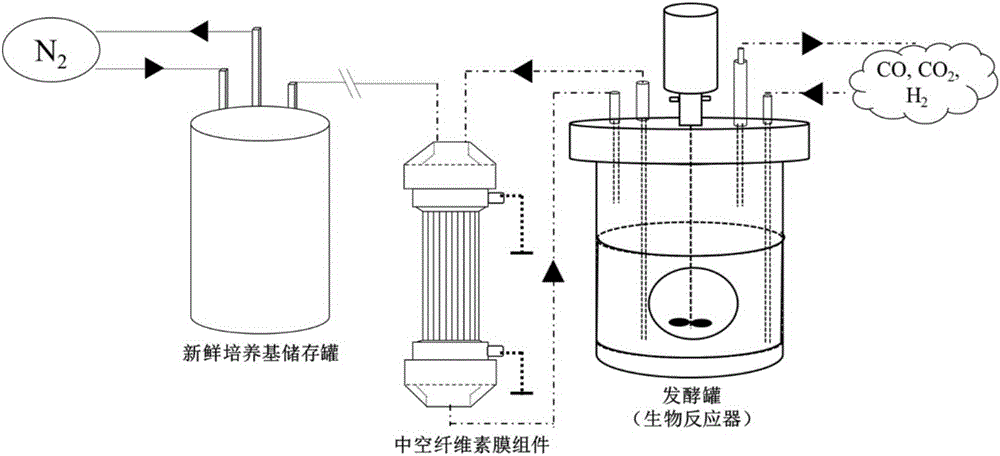

[0022] Use a hollow cellulose membrane to intercept and backflush the plateau fermentation broth: add 20ml of mineralsolutionstock, 0.5g of yeast extract, 5g of morpholineethanesulfonic acid, and 50ml of reducingagentStock to a 1L fermentation system, and extinguish at 121 degrees Bacteria 20min. After sterilization, cool to about 70 degrees, then add 1ml of trace element storage solution, replace the gas in the fermenter and fresh medium storage tank with nitrogen with a purity of 99.999%, and control the rate of nitrogen introduction at 500ml / min. When the temperature of the fermenter drops to about 37 degrees Celsius, install the heating jacket and stirring controller, connect the hollow cellulose membrane module, fermenter and fresh medium storage tank with a pressure-resistant hose, and turn off the nitrogen connected to the fermenter. Always maintain nitrogen gas connected to the fresh media storage tank. Feed simulated syngas (gas composition: 50% CO, 35% CO2, 15% H2) ...

Embodiment 2

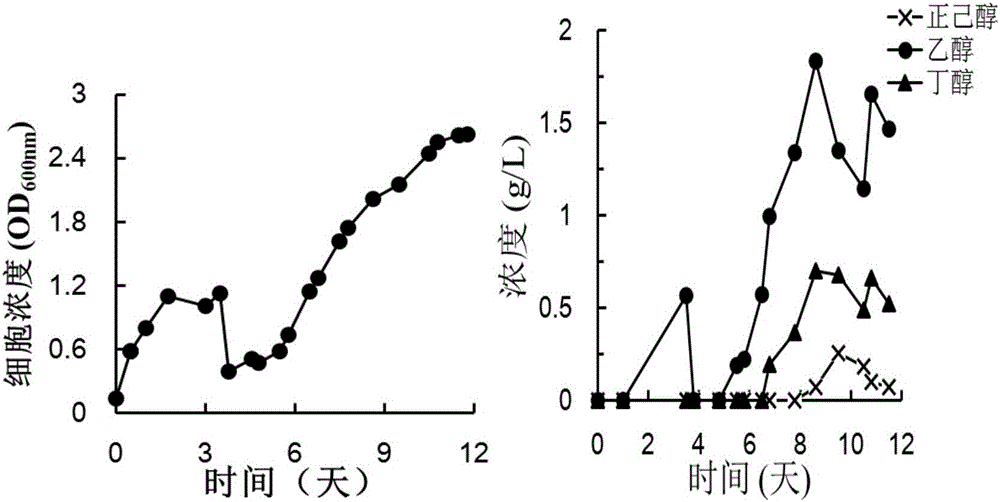

[0030] Retention backflushing of post-exponential broth using hollow cellulose membranes:

[0031] The culture medium preparation method and steps, device connection method and operation steps are the same as in Example 1, the difference is that the time point of cell interception is advanced to the post-exponential growth stage of the bacterial growth state.

[0032] Effect detection:

[0033]When the hollow cellulose membrane was used to intercept the late-exponential fermentation broth, and after washing and re-fermentation with fresh medium, first, the effective fermentation period of bacteria was also extended to 10 days, but the highest cell concentration reached 4.7Abs , is 3.9 times that of when the hollow cellulose membrane is not used, and the ethanol production is up to 1.6g / L, which is 2.7 times higher than that without the hollow cellulose membrane; the butanol production is up to 0.9g / L, which is comparable to Compared with the entrapment re-fermentation in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com