Labview-based semiconductor laser chip testing system

A test system and laser technology, applied in the field of test systems, can solve the problems of inability to meet the production and test requirements of different types of laser chips, poor test results and efficiency of new product development, and high prices, so as to reduce repetitive development work and test time. The effect of short, improved coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

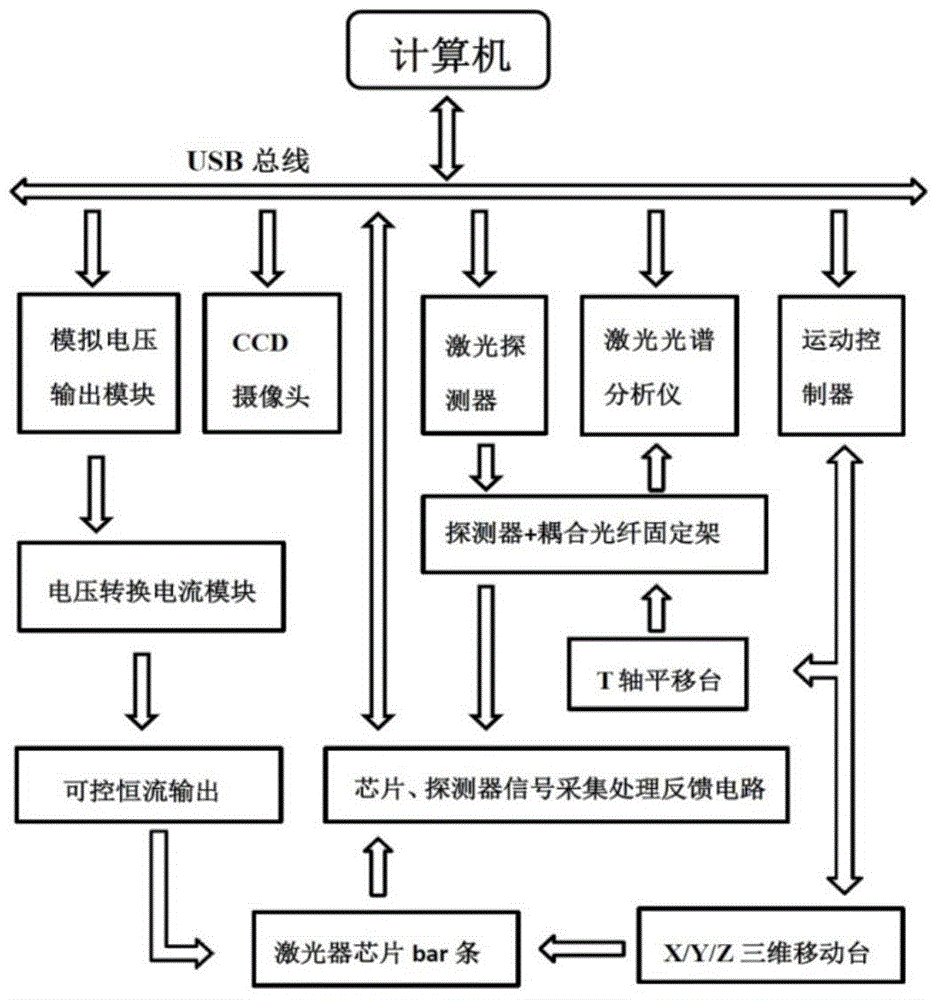

[0020] The computer is the core of the entire test system, with a friendly human-computer interaction interface, and it is the carrier of the laser chip test software. Install USB and other communication serial port protocol drivers on the computer, and add application software developed based on Labview to form a virtual instrument measurement and control platform, which realizes full-digital acquisition, test and analysis by computer, with rich software and hardware resources, automated test process, and extended It has the advantages of strong performance, high test accuracy, convenient later improvement, convenient operation, good repeatability, and high cost performance.

[0021] The four-axis motor controller receives the configuration command sent by the computer through the USB bus, and sends it to the four-axis motor through the signal line to control the rotation of the motor, so as to realize the precision of the X / Y / Z three-dimensional motion platform and the T-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com