Semi-suspension graphene field effect transistor preparation method

A field-effect transistor and suspended graphite technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of reducing carrier mobility, damage and contamination in graphene, and limiting the high frequency of graphene transistors Performance and other issues, to avoid damage and contamination, reduce parasitic, and ensure the integrity of the crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Overall, the present invention discloses a method for preparing a semi-suspended graphene field-effect transistor, the method comprising the steps of:

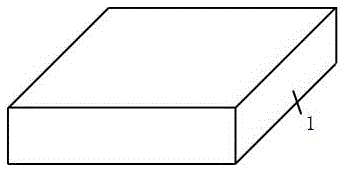

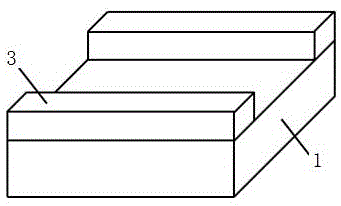

[0037] 1) On Substrate 1 (eg figure 1 As shown), the upper surface of the photoresist is coated, and the photolithography process is carried out to form the first photoresist pattern 3, such as figure 2 shown; the substrate can be SiO 2 , Si, SiC, sapphire, diamond, glass, mica or ceramics and other solid insulating substrates.

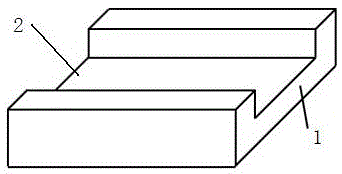

[0038] 2) Using the first photoresist pattern 3 on the upper surface of the substrate 1 as a mask, the substrate 1 is etched to form a substrate structure with grooves 2, such as image 3 Shown; groove size: depth 1 nm-100 μm, length and width 10 nm-100 μm.

[0039] 3) Metal-based graphene4 was prepared by chemical vapor deposition, such as Figure 4 As shown, the metal-based graphene is copper foil-based graphene or nickel foil-based graphene.

[0040] 4) Deposit a metal layer 5 on the u...

Embodiment 1

[0048] 1) First, prepare the substrate, the substrate used is insulating Si, such as figure 1 .

[0049] 2) Coating photoresist on the substrate, performing a photolithography process, and forming a photoresist pattern, such as figure 2 shown.

[0050] 3) Using the photoresist pattern formed in step 2) as a mask, the substrate is etched to a depth of 1 μm. After the etching is completed, the photoresist is removed to form a image 3 The substrate structure shown.

[0051] 4) Prepare metal-based graphene prepared by CVD method, the material used is copper foil-based graphene, such as Figure 4 shown.

[0052] 5) Using an electron beam evaporation station, in Figure 4 A layer of Au is deposited on the graphene of the shown structure with a thickness of 200nm to form a Figure 5 structure shown.

[0053] 6) put Figure 5 The shown graphene assembly with a bimetallic sandwich structure placed in a concentration of 1mol / L FeCl 3 In the etching solution, the Cu attached t...

Embodiment 2

[0059] 1) First, prepare the substrate, the substrate used is diamond, such as figure 1 .

[0060] 2) Coating photoresist on the diamond substrate, performing a photolithography process, and forming a photoresist pattern, such as figure 2 .

[0061] 3) Using the photoresist pattern formed in step 2) as a mask, the substrate is etched to a depth of 2 μm. After the etching is completed, the photoresist is removed to form a image 3 The substrate structure shown.

[0062] 4) Prepare metal-based graphene prepared by CVD method, the material used is copper foil-based graphene, such as Figure 4 shown.

[0063] 5) Using an electron beam evaporation station, in Figure 4 Deposit a layer of Pb on the graphene of the shown structure, the thickness is 100nm, forms as Figure 5 structure shown.

[0064] 6) put Figure 5 The shown graphene assembly with a bimetallic sandwich structure placed in a concentration of 1mol / L FeCl 3 In the etching solution, the Cu attached to the grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com