A kind of preparation method of nanocomposite conductive film for photovoltaic cell

A nano-composite, conductive thin film technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of limited anti-reflection effect of single silicon oxide-based anti-reflection film coating, electrostatic dust adsorption on the surface, etc., to achieve maintenance-free and Long-term work, high transmittance, and the effect of avoiding electrostatic dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

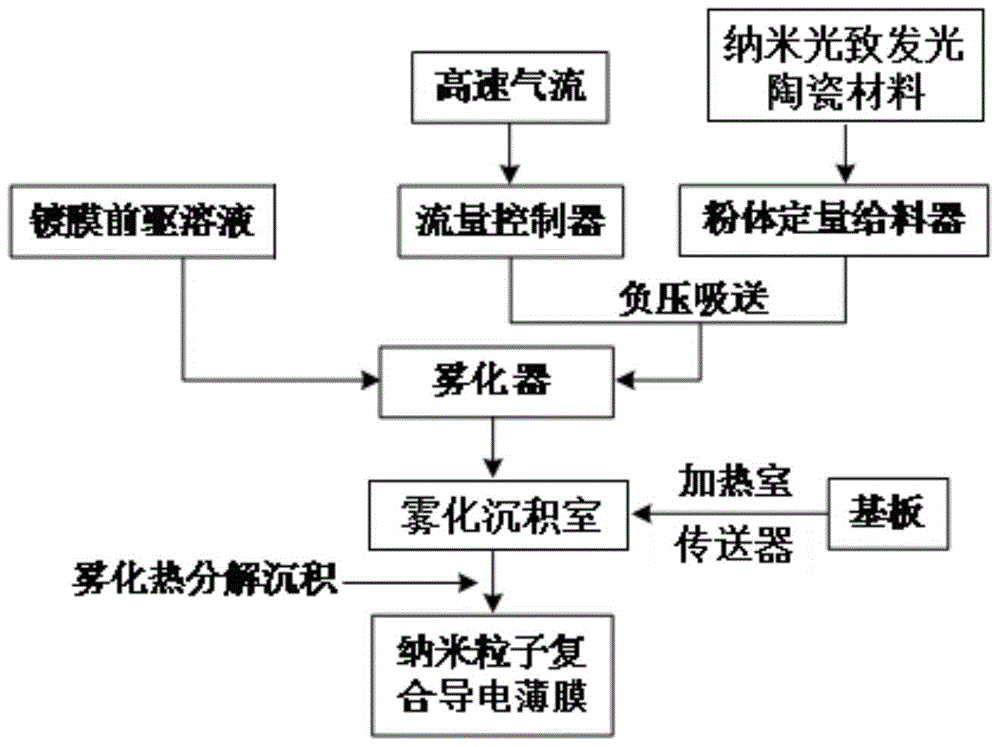

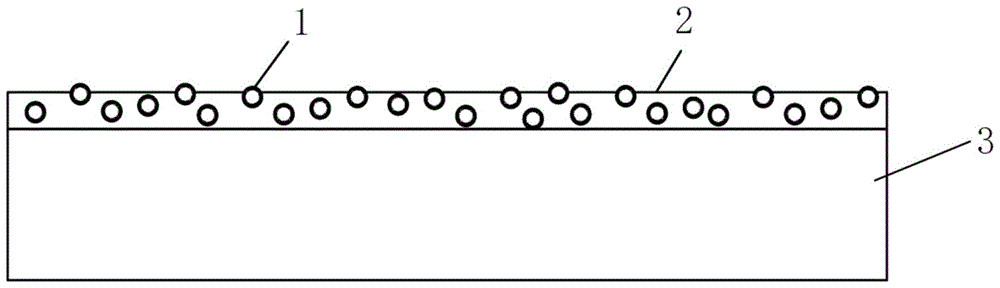

[0049] Step 1, prepare deposition aerosol:

[0050] 1.1 Europium-doped vanadium phosphate nano ceramic powder (Eu:YP x V (1-x) o 4 , x=0.4~0.6, commercially available, 15nm~20nm) put into the powder quantitative feeder, control the feeding speed to 0.1g / min~0.22g / min, adopt high-speed airflow siphon negative pressure to make nano photoluminescence The ceramic material forms an atomized air flow, and the air flow rate is controlled to be 1L / min~1.5L / min;

[0051] 1.2 The atomizing airflow atomizes the ATO (antimony-doped tin oxide) solution (concentration: 10wt% to 12wt%) in the water system in the atomizer to form a deposition aerosol, which is passed into the atomization deposition chamber.

[0052] Step 2, nanoparticle composite film deposition:

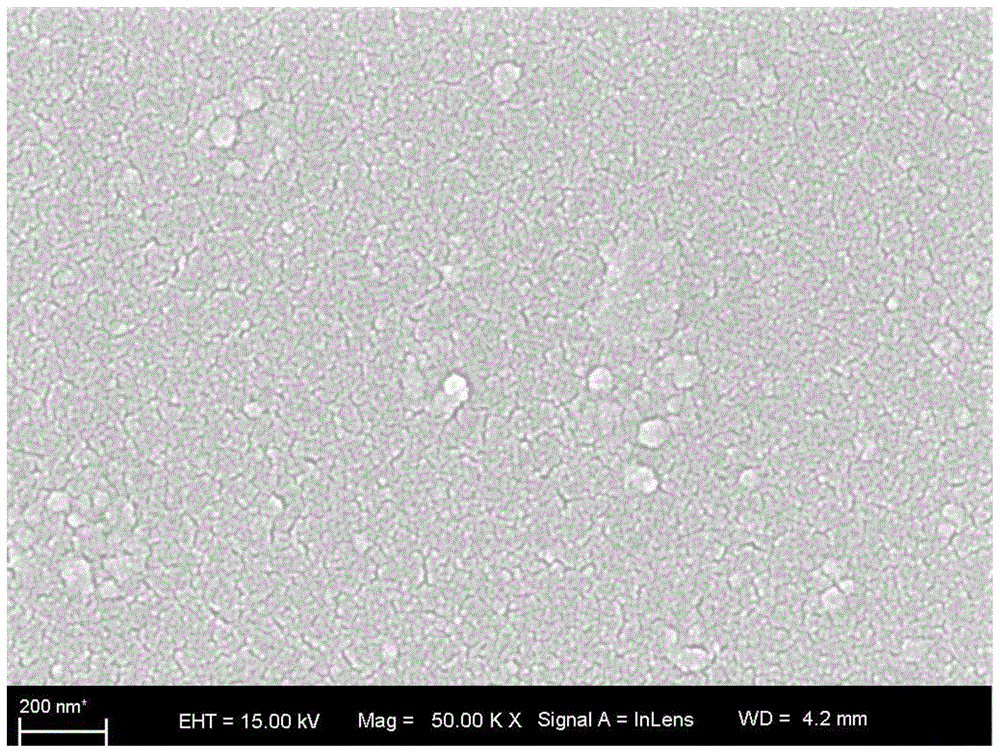

[0053] Heat the ultra-clear glass substrate for photovoltaic cells to 480°C-500°C in the heating chamber, send it into the atomization deposition chamber through the conveyor, and deposit the deposition mist on the substrate fo...

Embodiment 2

[0055] Step 1, prepare deposition aerosol:

[0056] 1.1 Europium-doped yttrium vanadate nano ceramic powder (Eu:YVO 4 , commercially available, 30nm ~ 40nm) into the powder quantitative feeder, control the feeding speed of 1.8g / min ~ 2g / min, use the high-speed airflow siphon negative pressure to make the nano photoluminescent ceramic material form an atomized airflow, Control the flow rate of airflow to 6L / min~7L / min;

[0057] 1.2 The atomizing gas flow atomizes the FTO (fluorine-doped tin oxide) solution (concentration: 15wt%-20wt%) of the water system in the atomizer to form a deposition aerosol, which is passed into the atomization deposition chamber.

[0058] Step 2, nanoparticle composite film deposition:

[0059] Heat the ultra-white glass substrate for photovoltaic cells to 500°C-520°C in the heating chamber, and send it into the atomization deposition chamber through the conveyor, so that the deposition mist is deposited on the substrate for 5-10s, and a photovoltaic...

Embodiment 3

[0061] Step 1, prepare deposition aerosol:

[0062] 1.1 Europium-doped yttrium vanadate nano ceramic powder (Eu:YVO 4 , commercially available, 20nm ~ 30nm) into the powder quantitative feeder, control the feeding speed of 0.5g / min ~ 0.8g / min, use high-speed airflow siphon negative pressure to make the nano-photoluminescent ceramic material form an atomized airflow , control the air flow rate to 4L / min~5L / min;

[0063] 1.2 Atomizing air flow ATO (antimony-doped tin oxide) solution (concentration: 15wt%-17wt%) in isopropanol system is atomized in the atomizer to form deposition aerosol, which is passed into the atomization deposition chamber.

[0064] Step 2, nanoparticle composite film deposition:

[0065] Heat the ultra-clear glass substrate for photovoltaic cells to 640°C-650°C in the heating chamber, send it into the atomization deposition chamber through the conveyor, and deposit the deposition mist on the substrate for 18-20s to obtain a photovoltaic cell with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com