Feed for broiler chickens having high dressing percentage and low abdominal fat percentage and preparation method of feed

A low abdominal fat rate, broiler feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of difficult to control preparation conditions, cumbersome production process, human health hazards, etc., to improve slaughter performance, improve growth performance, The effect of reducing abdominal fat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The broiler chicken feed with high slaughter rate and low abdominal fat rate of the present invention is composed of the following raw materials by weight:

[0021]

[0022]

[0023] The soybean lecithin powder is obtained by compounding and concentrating omega-3 fatty acid with soybean lecithin and mixing with puffed corn flour.

[0024] The mixing ratio of the soybean phospholipid compound concentrated omega-3 fatty acid and the puffed corn flour is 1:1.

[0025] In the soybean lecithin compound concentrated omega-3 fatty acid: the percentage content of the concentrated omega-3 fatty acid is 5.72%.

[0026] The soybean lecithin powder also includes the percentage composition: unsaturated fatty acid / saturated fatty acid=1.96%; n6:n3 fatty acid=2.63%; eicosapentaenoic acid (EPA)+docosahexaenoic acid (DHA) = 3.72%; total phospholipids 15%.

[0027] The lipase is a thermostable lipase.

[0028] The percentage content of acetone-insoluble matter in the soybean lec...

Embodiment 2

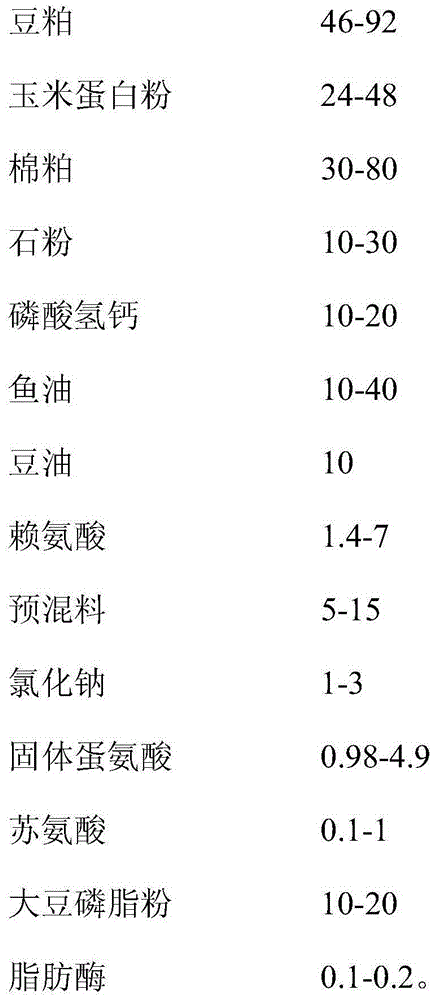

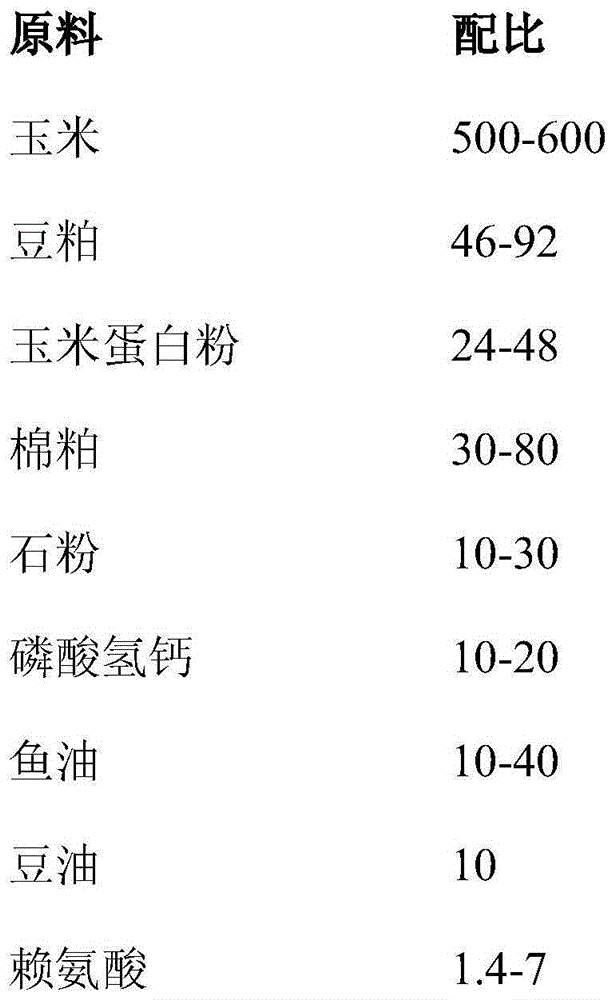

[0030] The broiler chicken feed with high slaughter rate and low abdominal fat rate of the present invention is composed of the following raw materials by weight:

[0031]

[0032]

[0033] The soybean lecithin powder is obtained by compounding and concentrating omega-3 fatty acid with soybean lecithin and mixing with puffed corn flour.

[0034] The mixing ratio of the soybean phospholipid compound concentrated omega-3 fatty acid and the puffed corn flour is 1:1.

[0035] In the soybean lecithin compound concentrated omega-3 fatty acid: the percentage content of the concentrated omega-3 fatty acid is 5.72%.

[0036] The soybean lecithin powder also includes the percentage composition: unsaturated fatty acid / saturated fatty acid=1.96%; n6:n3 fatty acid=2.63%; eicosapentaenoic acid (EPA)+docosahexaenoic acid (DHA) = 3.72%; total phospholipids 15%.

[0037] The lipase is a thermostable lipase.

[0038] The percentage content of acetone-insoluble matter in the soybean lec...

Embodiment 3

[0040] The broiler chicken feed with high slaughter rate and low abdominal fat rate of the present invention is composed of the following raw materials by weight:

[0041]

[0042] The soybean lecithin powder is obtained by compounding and concentrating omega-3 fatty acid with soybean lecithin and mixing with puffed corn flour.

[0043] The mixing ratio of the soybean phospholipid compound concentrated omega-3 fatty acid and the puffed corn flour is 1:1.

[0044] In the soybean lecithin compound concentrated omega-3 fatty acid: the percentage content of the concentrated omega-3 fatty acid is 5.72%.

[0045] The soybean lecithin powder also includes the percentage composition: unsaturated fatty acid / saturated fatty acid=1.96%; n6:n3 fatty acid=2.63%; eicosapentaenoic acid (EPA)+docosahexaenoic acid (DHA) = 3.72%; total phospholipids 15%.

[0046] The lipase is a thermostable lipase.

[0047] The percentage content of acetone-insoluble matter in the soybean lecithin is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com