Remedying method for removing chrome in contaminated soil of chromium slag site in situ

A technology of chromium-contaminated soil and remediation method is applied in the field of in-situ removal of chromium in contaminated soil from chromium slag sites, and can solve problems such as poor remediation effect of chromium-contaminated soil, achieve significant removal effect, facilitate unified treatment, and reduce unit energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A restoration method for removing chromium in soil in situ, comprising:

[0032] (1) Get the naturally air-dried chromium-contaminated soil, remove foreign matter therein, use a pulverizer to pulverize, cross a standard sieve with a particle size of 0.50 mm, and set aside;

[0033] (2) Mix the above-mentioned soil to be used with a citric acid solution with a concentration of 0.6-1.2mol / L to make the water content 25%-45%, stir well and then balance for one day;

[0034] (3) Take the above-mentioned balanced soil in the soil sample chamber of the electric restoration device, add 400-650 mesh filter cloths at both ends of the soil sample to prevent the soil from migrating to the cathode and anode chambers during the restoration process, and fill the cathode and anode chambers with electrolyte, The electrolyte is 0.05-0.15mol / L KCl solution;

[0035] (4) Insert the graphite electrode into the middle of the cathode and anode chamber, insert it to the bottom, connect the p...

Embodiment 2

[0040]In order to verify the effect of the remediation method in Example 1 on the removal of chromium in the actual chromium slag contaminated soil, the following experiments were carried out.

[0041] (1) Get the chromium-contaminated soil after natural air-drying (wherein, the total chromium content in the soil is 6612~16898mg / kg, the hexavalent chromium content is 944~2654mg / kg, pH=8.6~10.3), remove the impurities After pulverizing with a pulverizer, pass through a 0.50mm sieve for use;

[0042] (2) Mix 5.6Kg of the above-mentioned soil to be used with 2.4L of citric acid solution of 0.9mol / L, stir evenly with a stainless steel shovel, and let stand for one day;

[0043] (3) Get 7Kg of above-mentioned equalized soil in the soil sample room of the electric repair device, (the structure of the electric repair device is shown in embodiment 3), wherein, the soil sample room size is 30cm * 20cm * 10cm, the size of the negative and positive electrode chambers at both ends 10cm×2...

Embodiment 3

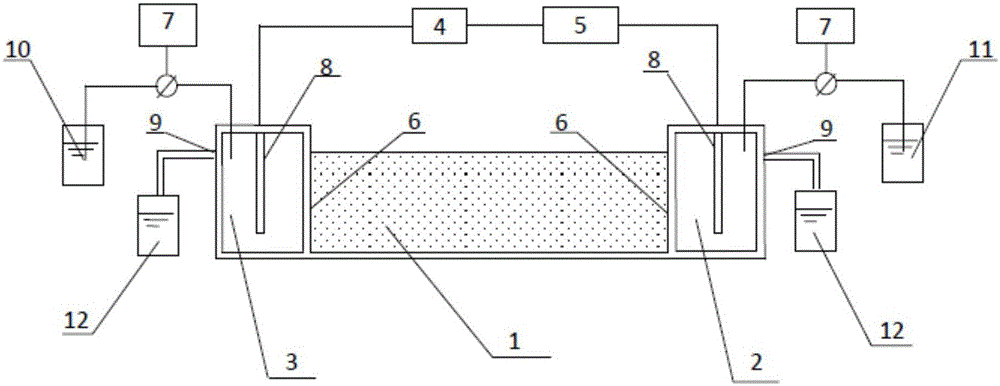

[0049] Embodiment 3 electric restoration device

[0050] The electric restoration device that the present invention adopts, as figure 1 As shown, it includes: soil sample chamber (1), anode chamber (2), cathode chamber (3), DC power supply (4), ammeter (5), filter screen (6), pH adjustment system (7), electrode ( 8), overflow hole (9), acid solution tank (10), alkali solution tank (11), collection tank (12).

[0051] Among them, the soil sample chamber (1) is used to fill the soil for testing, and its size ratio is length: width: height = 3:2:1. The anode chamber (2) is adjacent to the left and right sides of the soil sample chamber (1). 1. The dimensions of the cathode chamber (3), the anode chamber (2), and the cathode chamber (3) are length: width: height = 1:2:1. A strainer is pasted on the inner wall adjacent to the anode and cathode chambers of the soil sample chamber, an electrode 8 is arranged in the middle of the anode chamber and the cathode chamber, and the two el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com