Umbrella surface composite film and preparation method thereof, and fluorescent umbrella

A composite film and umbrella surface technology, applied in the field of umbrellas, can solve the problems of limiting the application of luminous film umbrellas, poor heat insulation effect of the umbrella, etc., and achieve good reflection infrared radiation and heat insulation effect, good reflection of near-infrared radiation, and blocking heat conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Correspondingly, the present invention also provides a preparation method of a composite film for an umbrella cover, comprising the following steps: mixing fluorescent powder with a polyurethane adhesive, and stirring to obtain a fluorescent paint; placing the fluorescent paint on a printing machine as a fluorescent ink In the process, the fluorescent paint is printed on the surface of the polypropylene film to form a fluorescent layer, and the polypropylene film is filled with hollow glass beads coated with titanium dioxide; the surface of the fluorescent layer is cast and coated with a polyurethane film to obtain an umbrella surface Composite film is used.

[0031] Wherein, the weight ratio of the fluorescent powder to the polyurethane binder is preferably 1:5-10, more preferably 1:6-8. The step of mixing the fluorescent powder and the polyurethane binder is preferably: stirring the fluorescent powder and the polyurethane binder at a weight ratio of 1:5-10 at a speed ...

Embodiment 1

[0048] Weigh 5 g of hollow glass microspheres, add them to a 500 mL four-neck flask, add 50 mL of distilled water, drop in 2 mL of 2% aqueous sodium dodecylbenzenesulfonate solution, stir, disperse, and heat up to 100°C. Adjust the pH value to 2.0-2.5 with 10% NaOH solution. Slowly add 10% Ti(SO 4 ) 2 solution, while adding dropwise a 10% NaOH solution to keep the pH value of the reaction solution. After the reaction, filter and wash the filter cake. The filter cake was dried in a blast oven at 120°C for 3h, and then calcined in a muffle furnace at 600°C for 2h to obtain TiO 2 Coated hollow glass microspheres.

[0049] in TiO 2 Add 50mL of distilled water to the coated hollow glass microspheres, stir evenly, disperse, heat up to 30-45°C, add organic surfactant trimethylchlorosilane, stir slowly, fully disperse, and then dry at room temperature to obtain two layers of surface modification hollow glass microspheres.

[0050] Put the polypropylene and the two layers of sur...

Embodiment 2

[0052] Fluorescent Umbrella Made by Gravure Printing

[0053] (1) Production of fluorescent umbrella surface:

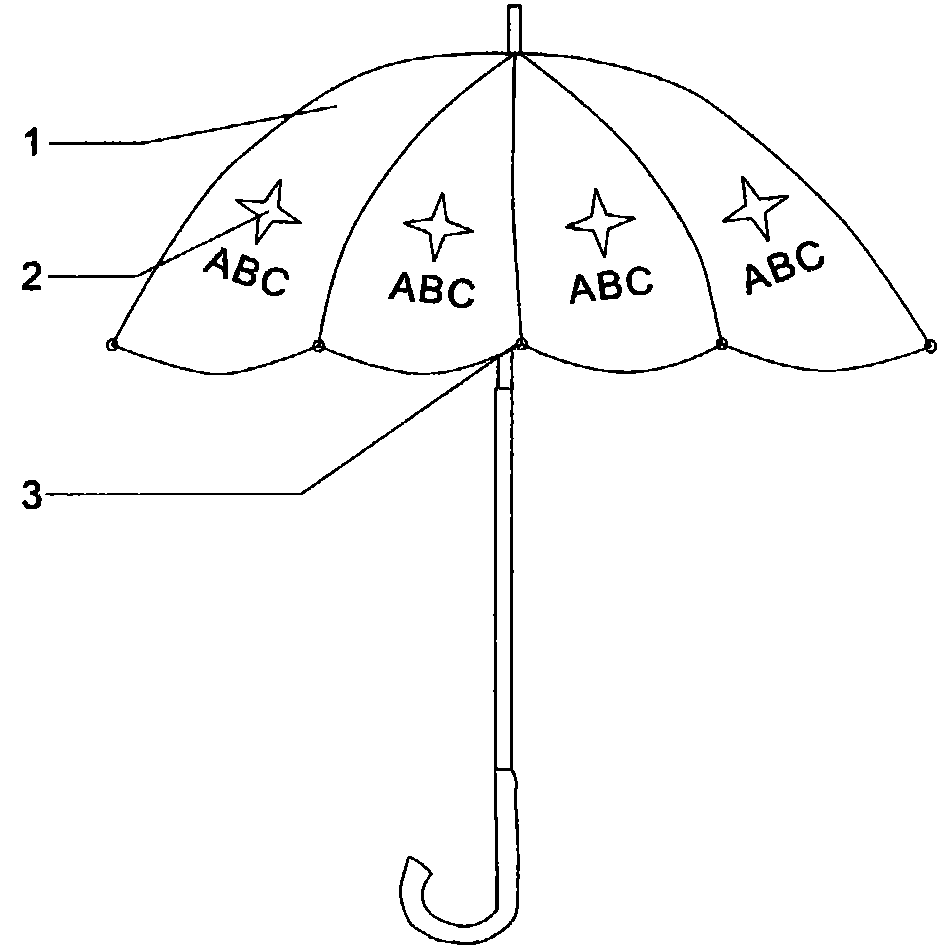

[0054] Stir 50g of fluorescent powder and 300g of polyurethane adhesive at a speed of 120rpm for 15-30min, and mix uniformly to make a fluorescent paint. The fluorescent paint is put into the ink fountain of the gravure printing machine as fluorescent ink, and the ABC pattern text information is arranged under the quadrangle through the laser. The engraving is made into a gravure plate and loaded on a gravure printing machine.

[0055] The hollow microbead composite polypropylene film prepared in Example 1 with a thickness of 80-140 μm is subjected to 6000-9000 volt high-voltage corona treatment, and its surface reaches more than 39 dynes, and then the polypropylene film is used as the substrate to print the above production The pattern and text, the thickness of the ink layer of the picture and text is 20-30μm, and the printed product is ventilated and dried in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com