A kind of preparation method of porous lithium iron phosphate cathode material

A technology of lithium iron phosphate and cathode materials, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of slow diffusion rate, unfavorable reversible reaction, difficult large-scale production, etc., to improve diffusion performance and conductivity , improve electrochemical performance, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

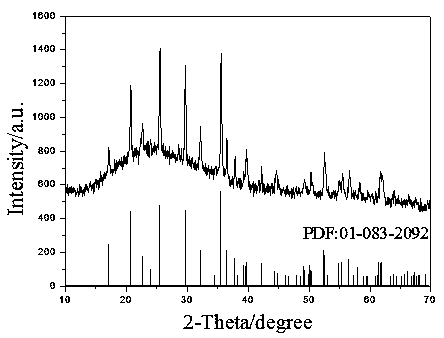

Image

Examples

Embodiment 1

[0026] A method for preparing a porous lithium iron phosphate cathode material. Described preparation method is:

[0027] 1) According to the solution concentration of 15~20Kg / m 3 , Dissolve potassium persulfate in deionized water and stir for 1 to 2 hours to obtain solution Ⅰ.

[0028] 2) According to the solution concentration of 2~3Kg / m 3 , Dissolve sodium lauryl sulfate in deionized water and stir for 0.5-1 hour to obtain solution II. Then according to the volume ratio of methyl methacrylate or styrene: solution II is 1:20~22, add methyl methacrylate or styrene to solution II, stir for 1~2 hours to obtain solution III.

[0029] 3) Under the condition of 70~90℃ and stirring, according to the volume ratio of solution I: solution III is 0.1~0.12:1, add solution I to solution III at a uniform speed, and the addition time is 0.5~1h, continue to stir for 4~5 hours, cooled to room temperature. Then wash with deionized water for 3 to 5 times, and dry to obtain a template, whi...

Embodiment 2

[0035] A method for preparing a porous lithium iron phosphate cathode material. Described preparation method is:

[0036] 1) According to the solution concentration of 10~15Kg / m 3 , Dissolve potassium persulfate in deionized water and stir for 1-2 hours to obtain solution I.

[0037] 2) According to the solution concentration of 1.5~2Kg / m 3 , Dissolve sodium lauryl sulfate in deionized water and stir for 0.5-1 hour to obtain solution II. Then according to the volume ratio of methyl methacrylate or styrene: solution II is 1:22~24, add methyl methacrylate or styrene to solution II, stir for 1~2 hours to obtain solution III.

[0038]3) Under the condition of 70~90℃ and stirring, according to the volume ratio of solution I: solution III is 0.12~0.14:1, add solution I to solution III at a uniform speed, and the addition time is 0.5~1h, continue to stir for 4~5 hours, cooled to room temperature. Then wash with deionized water for 3 to 5 times, and dry to obtain a template, whic...

Embodiment 3

[0044] A method for preparing a porous lithium iron phosphate cathode material. Described preparation method is:

[0045] 1) According to the solution concentration of 5~10Kg / m 3 , Dissolve potassium persulfate in deionized water and stir for 1 to 2 hours to obtain solution Ⅰ.

[0046] 2) According to the solution concentration of 1~1.5Kg / m 3 , Dissolve sodium lauryl sulfate in deionized water and stir for 0.5-1 hour to obtain solution II. Then according to the volume ratio of methyl methacrylate or styrene: solution II is 1:24~26, add methyl methacrylate or styrene to solution II, stir for 1~2 hours to obtain solution III.

[0047] 3) Under the condition of 70~90℃ and stirring, according to the volume ratio of solution I: solution III is 0.14~0.16:1, add solution I to solution III at a uniform speed, and the addition time is 0.5~1h, continue to stir for 4~5 hours, cooled to room temperature. Then wash with deionized water for 3 to 5 times, and dry to obtain a template, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com