a superfine ruo 2 Preparation method of nanoparticles

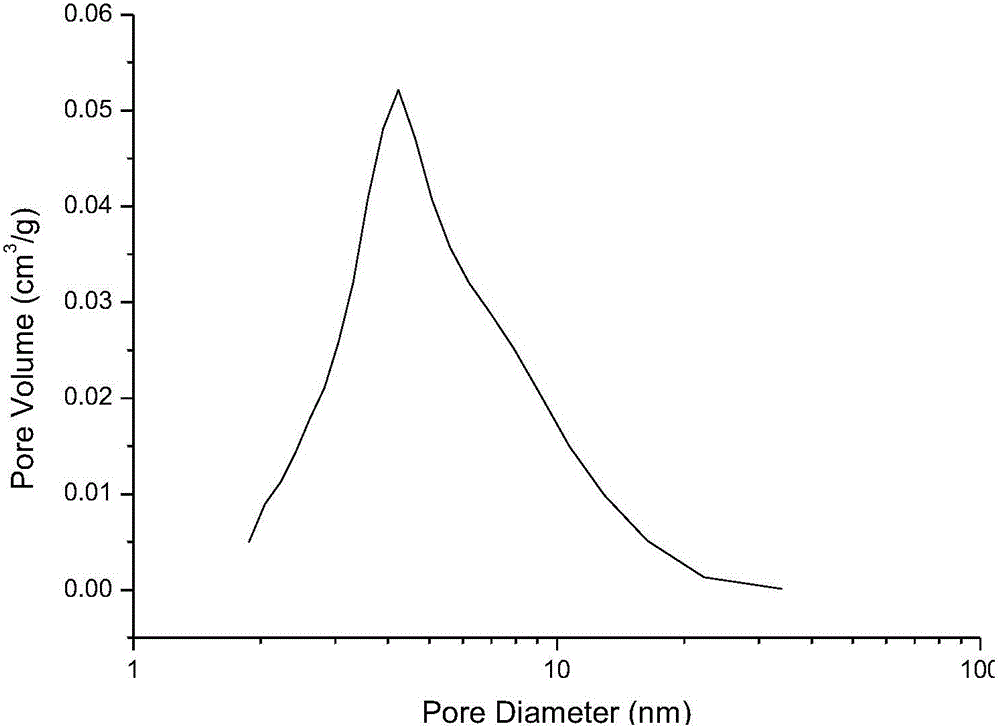

A nanoparticle, P123 technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of stable structure, adjustable particle size, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

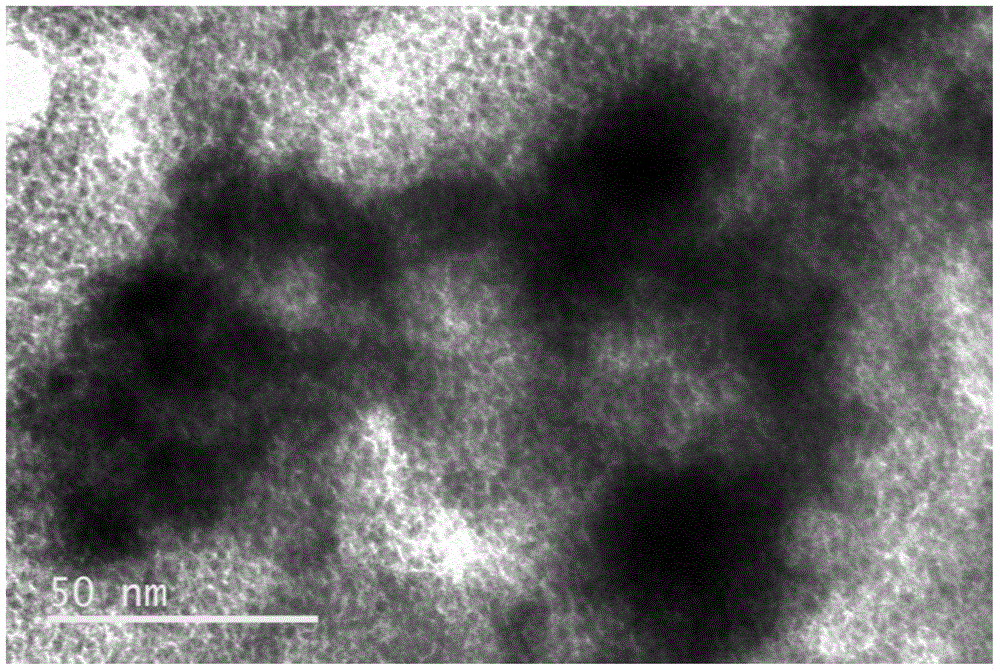

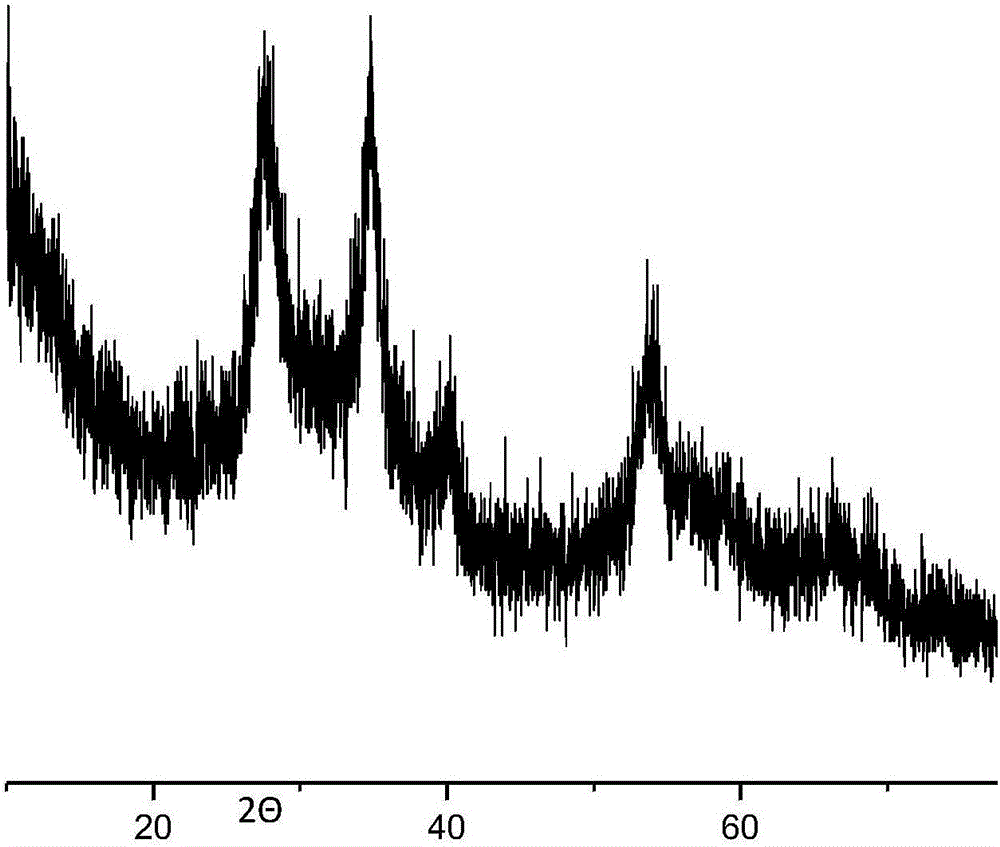

Image

Examples

Embodiment 1

[0023] 1. Dissolve 5g of P123 and 1mL of 1M HCl solution in 25g of ethanol, stir well to dissolve, add 10.4g of ethyl orthosilicate, and stir for 10 minutes with a magnet.

[0024] 2. Pour the above solution into a 6cm evaporating dish, put it in a cupboard, and let it stand for 48 hours.

[0025] 3. Pour 2-3mm thick liquid paraffin into the evaporating dish, put it into the blast drying oven, 90 degrees, and dry for 12 hours.

[0026] 4. Take the block out from the evaporating dish, and wipe off the liquid paraffin on the surface with filter paper.

[0027] 5. Anneal the above block at 900°C in air with a heating rate of 2°C / min for 1 hour to obtain mesoporous SiO 2 template.

[0028] 6. Put these hard templates in a 5cm petri dish, add 0.2mL of RuCl3 ethanol solution dropwise (every 5-7mL solution can contain 0.38g Ru element), wait until the ethanol is completely volatilized, continue to drop; repeatedly drop 5 Second-rate.

[0029] 7. Fill the RuCl 3 The template was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com