Preparation method of anti-fog self-cleaning glass with composite coating

A composite coating and self-cleaning technology, applied in the field of glass manufacturing, can solve the problems of low solar energy utilization, short composite time, short catalytic time, and reduced actual use value of titanium dioxide, and achieve excellent light transmittance, excellent self-cleaning, production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

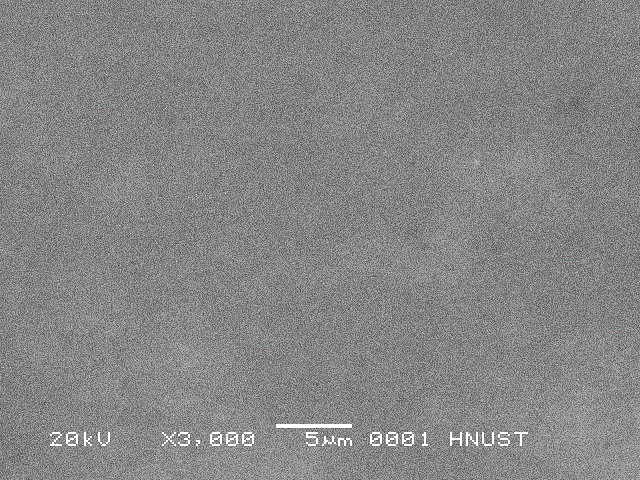

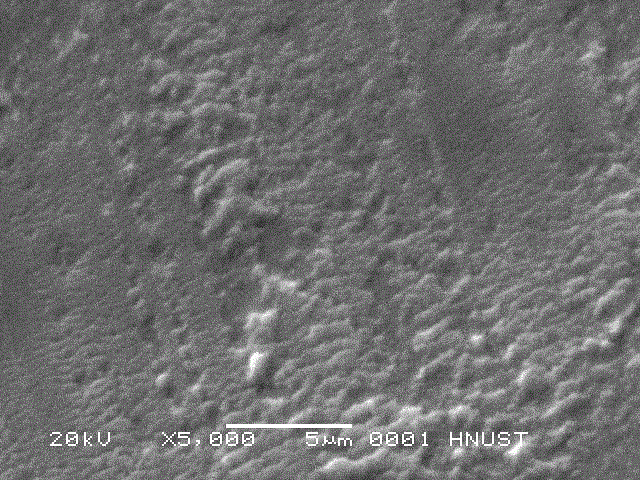

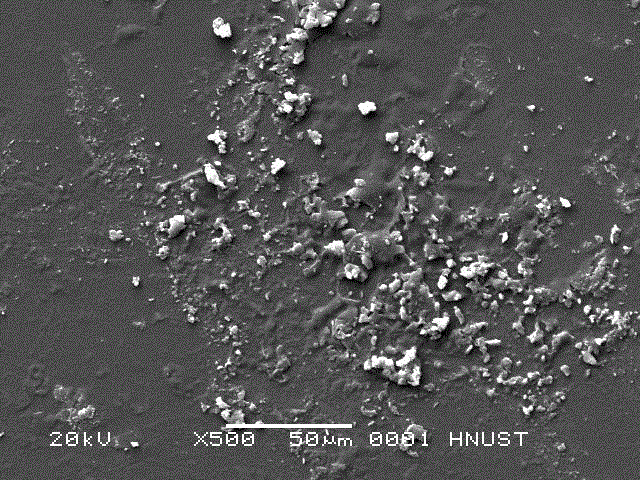

[0040] A method for preparing an anti-fog self-cleaning glass with a composite coating, comprising the following steps:

[0041] (1) Hydroxylation of ordinary glass surface: prepare piranha solution, control the temperature at 50-100°C, add cleaned ordinary glass, oxidize for 1-120min, wash with deionized water and dry after oxidation;

[0042] (2) Amination of the surface of the glass: put the glass obtained in step (1) in toluene, add a silane coupling agent whose terminal group is an amino group, stop the reaction after reflux for 5-30 hours, take out the glass piece, clean it ultrasonically and place it in dry at room temperature;

[0043] (3) Graphene oxide grafting: Add the glass obtained in step (2) to the graphene oxide organic solvent, under the action of a dehydrating agent, stop the reaction after reflux for 5-24 hours, take out the glass, ultrasonically clean it and place it at room temperature down to dry;

[0044] (4) Deposition of titanium dioxide nanoparticle...

Embodiment 1

[0048] A method for preparing an anti-fog self-cleaning glass with a composite coating, comprising the following steps:

[0049] (1) Hydroxylation of ordinary glass surface: firstly cut the ordinary glass sheet into 20*20mm, ultrasonic cleaning; then prepare piranha solution, control the temperature at 80°C, add clean ordinary glass, control the oxidation time at 60min, and use it after stopping Rinse with deionized water and dry;

[0050] (2) Amination of the glass surface terminal: put the hydroxylated glass flakes in 100mL of toluene, add 5mL of γ-aminopropyltrimethoxysilane, stop the reaction after refluxing for 24 hours, take out the glass flakes, and use ethanol and water to sonicate Wash and dry at room temperature;

[0051] (3) Graphene oxide grafted glass: Add the amino-terminated glass to 1 mg / mL graphene oxide methanol, and add dehydrating agent DCC, stop the reaction after reflux for 24 hours, take out the glass piece, and use ethanol and water to sonicate Wash a...

Embodiment 2

[0054] A method for preparing an anti-fog self-cleaning glass with a composite coating, comprising the following steps:

[0055] (1) Hydroxylation of ordinary glass surface: firstly cut the ordinary glass sheet into 20*20mm, ultrasonic cleaning; then configure piranha solution, control the temperature at 50°C, add clean ordinary glass, control the oxidation time at 120min, and use it after stopping Rinse with deionized water and dry;

[0056] (2) Amination of the surface of the glass: put the hydroxylated glass on the surface in 100mL of toluene, add 10mL of γ-aminopropyltrimethoxysilane, stop the reaction after refluxing for 5 hours, take out the glass, and use ethanol and water to sonicate Wash and dry at room temperature;

[0057] (3) Graphene oxide grafted glass: Add the amino-terminated glass to 1 mg / mL graphene oxide ethanol, and add dehydrating agent EDC, stop the reaction after reflux for 12 hours, take out the glass piece, wash with ethanol, water Ultrasonic cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com