Thermal insulation mortar containing papermaking sludge ash and preparation method thereof

A technology of papermaking sludge ash and thermal insulation mortar, which is applied in the field of building materials, can solve the problems that the treatment method and utilization status of papermaking sludge ash are not specified in detail, and achieve good economic and social benefits, cost reduction, and stable physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

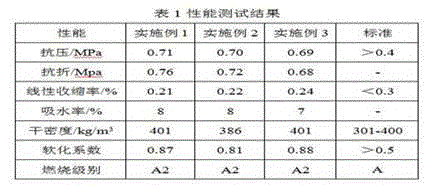

Embodiment 1

[0023] A thermal insulation mortar containing papermaking sludge ash, which is composed of the following raw materials in parts by weight: 100 parts of sulphoaluminate cement, 21 parts of papermaking sludge ash, 5 parts of polyphenylene particles, 9 parts of vitrified microbeads, fiber 0.6 parts of plain ether, 0.4 parts of air-entraining agent, 0.7 parts of polycarboxylate superplasticizer, 0.4 parts of alkali-resistant glass fiber, and 50 parts of water.

[0024] As mentioned above, the papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 400-850° C., sieved with a 200-mesh sieve, and the residue is less than 10%.

[0025] As mentioned above, the main components of papermaking sludge ash are calcium aluminosilicate and anhydrous calcium sulfate.

[0026] Described, the particle diameter of polyphenylene particle is 2-5mm, and bulk density is 8.9kg / m 3 .

[0027] Described, the air-entraining agent is sodium dodecylbenzenesulfonate.

[0028] ...

Embodiment 2

[0034] A thermal insulation mortar containing papermaking sludge ash, which is composed of the following raw materials in parts by weight: 100 parts of sulphoaluminate cement, 20 parts of papermaking sludge ash, 4 parts of polyphenylene particles, 8 parts of vitrified microbeads, fiber 0.5 parts of plain ether, 0.3 parts of air-entraining agent, 0.6 parts of polycarboxylate superplasticizer, 0.3 parts of alkali-resistant glass fiber, and 55 parts of water.

[0035] As mentioned above, the papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 400-850° C., sieved with a 200-mesh sieve, and the residue is less than 10%.

[0036] As mentioned above, the main components of papermaking sludge ash are calcium aluminosilicate and anhydrous calcium sulfate.

[0037] Described, the particle diameter of polyphenylene particle is 2-5mm, and bulk density is 8.9kg / m 3 .

[0038] Described, the air-entraining agent is sodium dodecylbenzenesulfonate.

[0039] ...

Embodiment 3

[0045] A thermal insulation mortar containing papermaking sludge ash, which is composed of the following raw materials in parts by weight: 100 parts of sulphoaluminate cement, 19 parts of papermaking sludge ash, 3 parts of polyphenylene particles, 7 parts of vitrified microbeads, fiber 0.4 parts of plain ether, 0.2 parts of air-entraining agent, 0.5 parts of polycarboxylate superplasticizer, 0.2 parts of alkali-resistant glass fiber, and 60 parts of water.

[0046] As mentioned above, the papermaking sludge ash is the powder obtained by incinerating papermaking sludge at 400-850° C., sieved with a 200-mesh sieve, and the residue is less than 10%.

[0047] As mentioned above, the main components of papermaking sludge ash are calcium aluminosilicate and anhydrous calcium sulfate.

[0048] Described, the particle diameter of polyphenylene particle is 2-5mm, and bulk density is 8.9kg / m 3 .

[0049] Described, the air-entraining agent is sodium dodecylbenzenesulfonate.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com