Straw biological-organic silicon-potassium ferment bacterial manure and preparation method thereof

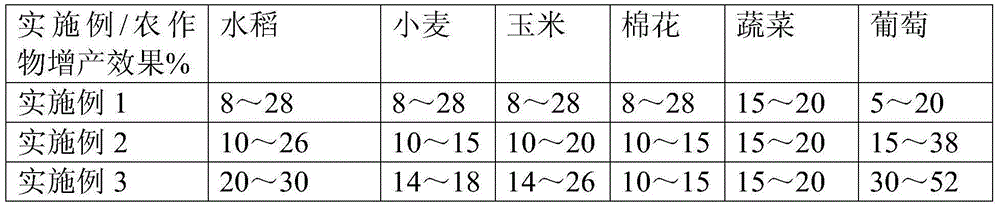

The technology of silicon-potassium enzyme and straw is applied in the field of straw bioorganic silicon-potassium enzyme bacterial fertilizer and its preparation, which can solve the problems of secondary pollution of farmland, difficulty in ensuring fertilizer efficiency and high difficulty in fermentation of straw, and avoid air pollution. , Promoting a virtuous cycle, the effect of increasing production is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

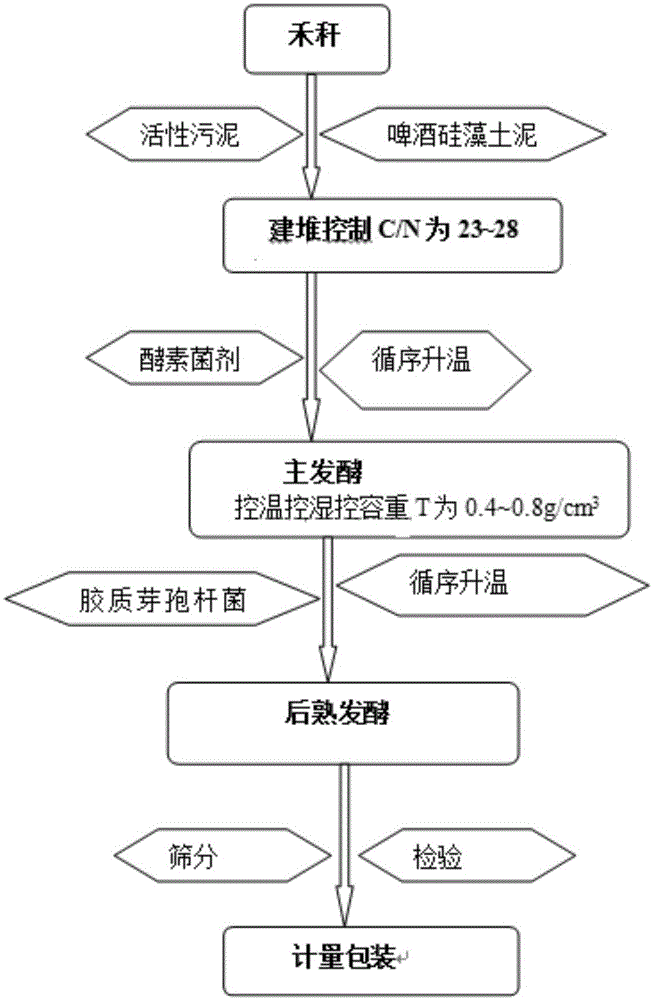

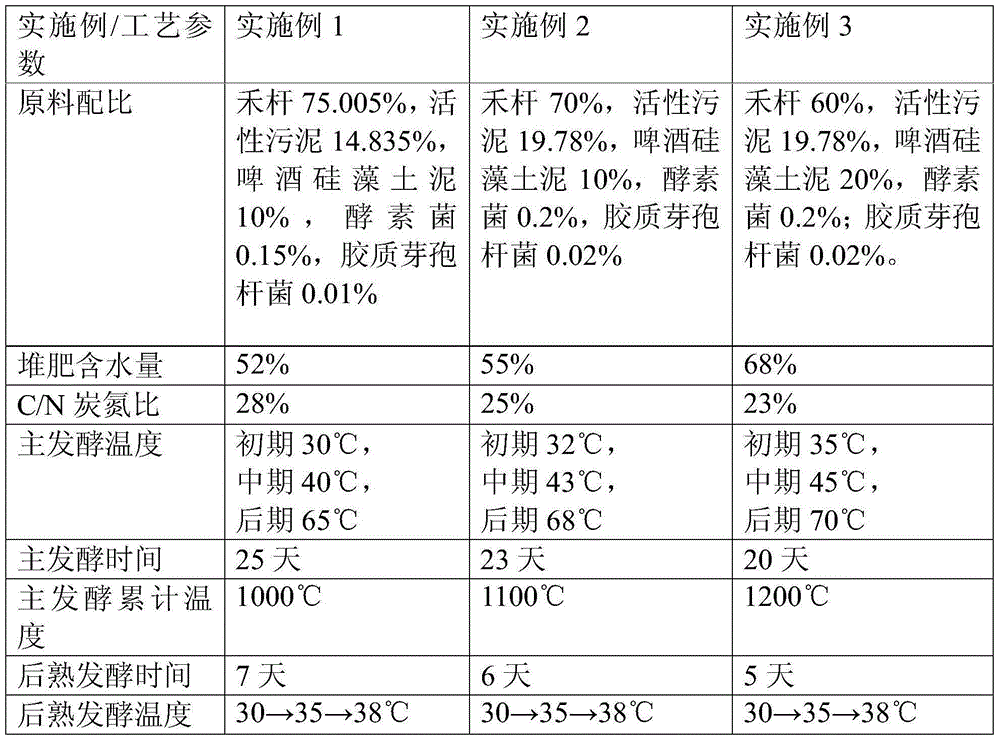

[0050] Such as figure 1 Shown, the preparation method of straw bioorganosilicon potassium ferment bacterial fertilizer of the present invention comprises the following steps (ton scale operation):

[0051] (1) Prepare materials: 60-80% of straw, 9.89-19.78% of activated sludge, 10-20% of beer diatomite mud, 0.1-0.2% of starter, and 0.01-0.02% of silicate bacteria. Compared with preparing raw materials, the straws used in the embodiments are the air-dried rice straws and leaves left after harvesting the seeds, and the stems and leaves of crops such as wheat, corn, and soybeans can also be used, and the straws are crushed or cut into 1 to 2 The activated sludge is a sludge filter cake that has undergone in-situ reduction of OSA-compound enzyme sludge, harmless treatment, and squeezed by a diaphragm filter press. Its solid content is 50% to 60%, and its organic matter The content is 300-600g / kg, the nitrogen content is 20-50g / kg, and the phosphorus content is 10-20g / kg; beer dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com