Batch distillation process for separating isopropanol-isopropyl acetate azeotrope through mixed extraction agent

A technology of isopropyl acetate and mixed extractant, applied in the field of isopropyl alcohol-isopropyl acetate azeotrope extraction and rectification, can solve problems such as high investment cost, high energy consumption cost, difficult industrial application, etc. The effect of production cost and energy consumption, reduction of separation energy consumption, improvement of product purity and extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

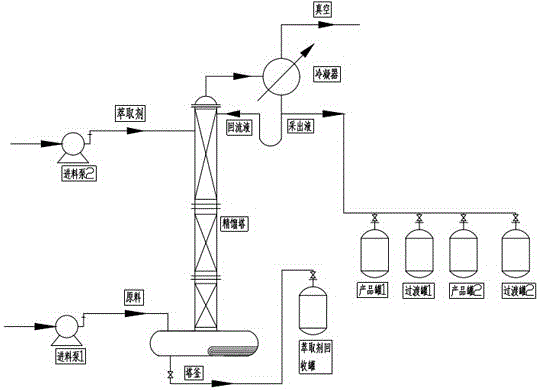

Image

Examples

Embodiment 1

[0018] A batch rectification process for separating isopropanol-isopropyl acetate azeotrope with mixed extractant. The extractant is selected from ethylene glycol and 1-ethyl-3-methylimidazolium tetrafluoroborate ([Emim][BF 4 ]) (20wt%); the raw material processing capacity is 1000kg, the raw material composition is a near-azeotropic composition of isopropanol (55wt%) and isopropyl acetate (45wt%), and the ratio of extraction agent dosage to raw material feed is 3~5 : 1, the number of extraction and rectification column trays is 60, and the extraction agent feeding position is at the 5th tray. The reflux ratio is set to 4. When the tower top temperature reaches 75~76°C, the isopropanol with a content ≥99.5% is extracted to the product tank 1 with a reflux ratio of 5:1; when the isopropanol extracted from the top of the extractive distillation tower When the alcohol product content is less than 98% and the tower top temperature is higher than 80°C, stop adding the extractant, ...

Embodiment 2

[0020] As the extractant, ethylene glycol and 1-butyl-3-methylimidazolium dibutyl phosphate ([bmim][dbp]) were selected, and other conditions were as in Example 1. The purity of the obtained isopropyl acetate and isopropanol products is more than 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com